Laser rapid preparation method of inorganic molybdenum disulfide microsphere with fullerene like structure

A technology of fullerene molybdenum disulfide and molybdenum disulfide, applied in the fields of molybdenum sulfide, petroleum industry, additives, etc., can solve the problems of cumbersome preparation process and harsh conditions, and achieve simple process, easy control of conditions and low preparation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Weigh 750mg of original molybdenum disulfide powder (purity 98%, particle size 800nm) into a 100mL beaker, add 50mL dimethylformamide, and ultrasonically disperse for 30min to form a suspension;

[0037] (2) Irradiate the suspension prepared in the above step (1) with the krypton-fluorine laser beam (248nm) focused by the mirror and convex lens, and ablate the molybdenum disulfide powder in the solvent. The laser energy density is 1800mJpulse -1 cm -1 , the frequency is 10Hz, the laser pulse is 5ns, and the irradiation time is 20min. During laser beam irradiation, the container containing the suspension was placed in an ice-water mixture to keep the temperature low, and the suspension was continuously stirred with a magnetic stirrer at a speed of 1500 r / min.

[0038] (3) After irradiation, centrifuge the suspension, and then dry the powder at 60°C to obtain the product.

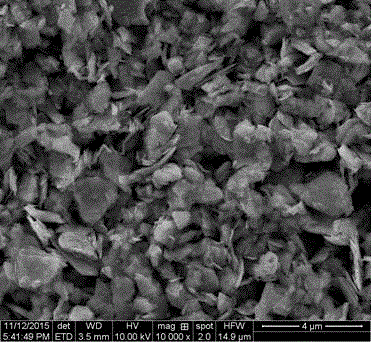

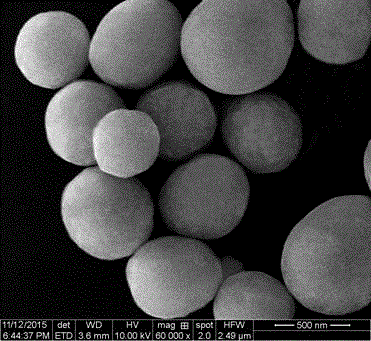

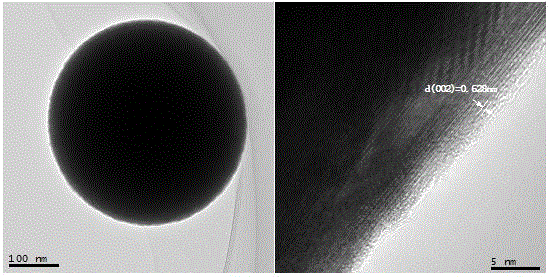

[0039] figure 1 It is the scanning electron microscope picture of the original molybdenum disu...

Embodiment 2

[0041] (1) Weigh 250mg of original molybdenum disulfide powder (purity 98%, particle size 600nm) into a 100mL beaker, add 50mL dimethylformamide, and ultrasonically disperse for 20min to form a suspension.

[0042] (2) Irradiate the suspension prepared in the above step (1) with the krypton-fluorine laser beam (248nm) focused by the mirror and convex lens, and ablate the molybdenum disulfide powder in the solvent. The laser energy density is 1600mJpulse -1 cm -1 , the frequency is 8Hz, the laser pulse is 25ns, and the irradiation time is 30min. During the laser beam irradiation process, the container containing the suspension was placed in an ice-water mixture to keep the temperature low, and the suspension was continuously stirred with a magnetic stirrer at a speed of 1000 r / min.

[0043] (3) After the irradiation, the suspension was centrifuged, and the powder was dried at 60°C to obtain fullerene-like molybdenum disulfide microspheres. The appearance of the product obtain...

Embodiment 3

[0045] (1) Weigh 25mg of original molybdenum disulfide powder (purity 98%, particle size 400nm) into a 100mL beaker, add 50mL dimethylformamide, and ultrasonically disperse for 10min to form a suspension.

[0046] (2) Irradiate the suspension prepared in the above step (1) with the krypton-fluorine laser beam (248nm) focused by the mirror and the convex lens, and ablate the molybdenum disulfide powder in the solvent, and the laser energy density is 1000mJpulse -1 cm -1 , the frequency is 5Hz, the laser pulse is 50ns, and the irradiation time is 40min. During laser beam irradiation, the container containing the suspension was placed in a mixture of ice and water to keep the temperature low, and the suspension was continuously stirred with a magnetic stirrer at a speed of 800 r / min.

[0047] (3) After the irradiation, the suspension was centrifuged, and the powder was dried at 60°C to obtain fullerene-like molybdenum disulfide microspheres. The appearance of the product obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com