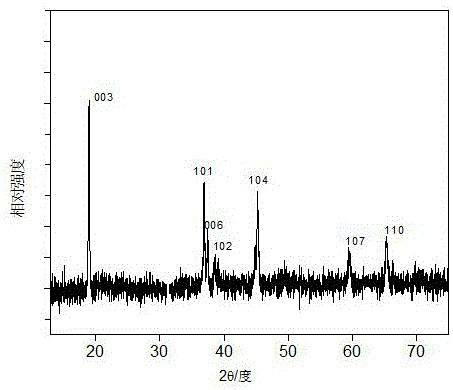

Preparation method and application of high-purity lithium cobalt oxide cathode material

A pure lithium cobalt oxide, cathode material technology, applied in chemical instruments and methods, battery electrodes, cobalt compounds, etc., can solve the problems of high equipment requirements, large investment, etc., to achieve high purity, high specific capacity, and cycle capacity does not decay Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

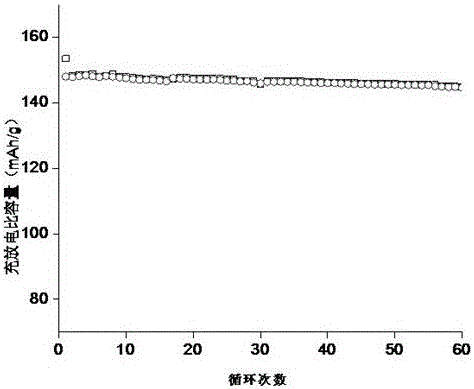

Embodiment 1

[0032] Weigh 1.6g of cobalt tetroxide, 0.2g of PVDF and 0.2g of acetylene black, grind them in a mortar for half an hour and mix well, take 0.2g of the mixture and put it into a mold, and press it under 20MPa for 1 minute to form a tablet. Use the pressed sheet as the positive electrode, select the CR2032 button battery case, assemble the battery in the order of the negative electrode case, spring sheet, gasket, lithium sheet, diaphragm, positive electrode, and positive electrode case, add 5 drops of lithium-ion battery electrolyte, and seal it with a sealing machine Prepare button cells. Put the prepared button battery on a battery tester, and discharge it at a constant current of 0.05C to a capacity of 53.42mAh. The lithium intercalated cobalt tetroxide was taken out and kept in a muffle furnace at 550° C. for 15 hours to obtain lithium cobalt oxide.

[0033] Mix the obtained lithium cobaltate with the conductive agent acetylene black and the binder PVDF at a mass ratio of ...

Embodiment 2

[0036] Weigh 12g of cobalt tetroxide, 4g of PVDF, 2g of acetylene black and 2g of SuperP, put them into a 100ml ball mill jar with a ball-to-material ratio of 3:1, grind for 2 hours and mix well, take 0.2g of the mixture and put it into a mold, press it under 15MPa for 1 minute to form a tablet . Use the pressed sheet as the positive electrode, select the CR2032 button battery case, assemble the battery in the order of the negative electrode case, spring sheet, gasket, lithium sheet, diaphragm, positive electrode, and positive electrode case, add 5 drops of lithium-ion battery electrolyte, and seal it with a sealing machine Prepare button cells. Put the prepared button battery on the battery tester, and discharge it at a constant current of 0.05C to a capacity of 40.07mAh. The lithium intercalated cobalt tetroxide was taken out, and kept in a muffle furnace at 800° C. for 8 hours to obtain lithium cobalt oxide.

[0037] Mix the obtained lithium cobalt oxide with the conducti...

Embodiment 3

[0040] Weigh 1.8g of cobalt tetroxide, 0.1g of PVDF and 0.1g of carbon nanotubes, grind them in a mortar for half an hour and mix well, take 0.2g of the mixture and put it into a mold, and press it under 30MPa for 1 minute to form a tablet. Use the pressed sheet as the positive electrode, select the CR2032 button battery case, assemble the battery in the order of the negative electrode case, spring sheet, gasket, lithium sheet, diaphragm, positive electrode, and positive electrode case, add 5 drops of lithium-ion battery electrolyte, and seal it with a sealing machine Prepare button cells. Put the prepared button battery on a battery tester, and discharge it at a constant current of 0.05C to a capacity of 60.10mAh. The lithium intercalated cobalt tetroxide was taken out, and kept in a muffle furnace at 400° C. for 24 hours to obtain lithium cobalt oxide.

[0041] Mix the obtained lithium cobalt oxide with the conductive agent acetylene black and the binder PVDF at a mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com