Heavy metal sewage treatment particles and preparation method thereof

A technology for sewage treatment and heavy metals, which is applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of low cleaning efficiency, high operation difficulty, poor cleaning effect, etc. Water source, the effect of reducing water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

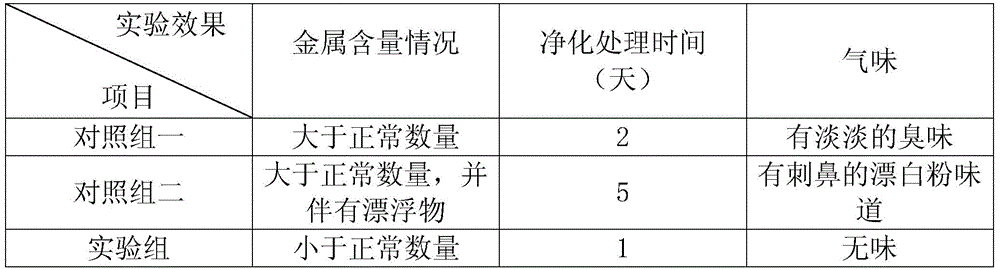

Examples

Embodiment 1

[0020] A heavy metal sewage treatment granule, made of the following materials in proportion by weight: 23 parts of activated carbon, 8 parts of chitosan, 14 parts of epoxy resin, 10 parts of sepiolite, 7 parts of montmorillonite, alginic acid 9 parts of gelatin, 6 parts of alum, 5 parts of barium sulfide, 8 parts of calcium carbonate, 11 parts of cellulose base, 4 parts of nano-titanium dioxide, 6 parts of hydrotalcite, 13 parts of silica gel and 9 parts of sodium hydrosulfide.

[0021] A preparation method for heavy metal sewage treatment particles, comprising the following steps:

[0022] 1) Mix 23 parts of activated carbon, 10 parts of sepiolite, 7 parts of montmorillonite and 6 parts of hydrotalcite, and then grind the above-mentioned materials through a grinder to make powder and set aside;

[0023] 2) Vibrating and screening the powder prepared in step 1) through a vibrating sieve, separating the coarse particles and fragments in the powder from the powder to obtain a 5...

Embodiment 2

[0031] A heavy metal sewage treatment particle, made of the following materials in proportion by weight: including 11 parts of activated carbon, 16 parts of chitosan, 26 parts of epoxy resin, 18 parts of sepiolite, 13 parts of montmorillonite, alginic acid 15 parts, gelatin 14 parts, alum 25 parts, barium sulfide 10 parts, calcium carbonate 14 parts, cellulose base 16 parts, nano titanium dioxide 8 parts, hydrotalcite 14 parts, silica gel 19 parts and sodium hydrosulfide 19 parts.

[0032] A preparation method for heavy metal sewage treatment particles, comprising the following steps:

[0033] 1) Take 11 parts of activated carbon, 18 parts of sepiolite, 13 parts of montmorillonite and 14 parts of hydrotalcite and mix them, then grind the above-mentioned materials through a grinder to make powder and set aside;

[0034] 2) Vibrating and screening the powder prepared in step 1) through a vibrating sieve, separating the coarse particles and fragments in the powder from the powder...

Embodiment 3

[0042] A heavy metal sewage treatment granule, made of the following materials in proportion by weight: 17 parts of activated carbon, 12 parts of chitosan, 20 parts of epoxy resin, 14 parts of sepiolite, 10 parts of montmorillonite, alginic acid 12 parts, gelatin 10 parts, alum 20 parts, barium sulfide 8 parts, calcium carbonate 11 parts, cellulose base 14 parts, nano titanium dioxide 6 parts, hydrotalcite 10 parts, silica gel 16 parts and sodium hydrosulfide 15 parts.

[0043] A preparation method for heavy metal sewage treatment particles, comprising the following steps:

[0044] 1) Mix 17 parts of activated carbon, 14 parts of sepiolite, 10 parts of montmorillonite and 10 parts of hydrotalcite, and then grind the above-mentioned materials through a grinder to make powder for later use;

[0045] 2) Vibrating and screening the powder prepared in step 1) through a vibrating sieve, separating the coarse particles and fragments in the powder from the powder to obtain a 50-mesh m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com