Artificial red agate made from coal gangue and making method thereof

A coal gangue and agate technology, which is applied in the field of artificial onyx and its manufacture, can solve the problems of limited onyx resources, unstable quality, and ecological environment hazards, and achieve high practicality and promotion and application value. The preparation process is simple and the price is low. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

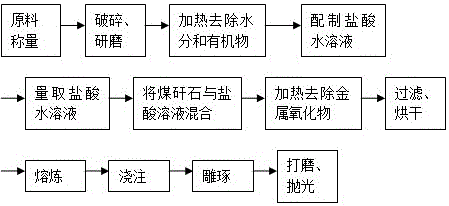

[0032] Example 1: Press figure 1 As shown, the production raw materials and proportions:

[0033] Coal gangue: 100%.

[0034] The preparation method of artificial red agate is:

[0035] (1) Weigh a certain weight of coal gangue;

[0036] (2) Crushing and grinding massive coal gangue raw materials;

[0037] (3) Put the coal gangue that has been ground into powder into a heat treatment furnace for heating to remove moisture and organic matter in the gangue. The feature is: put the coal gangue powder into a crucible, put it into the heat treatment furnace at room temperature, and heat up with the furnace; The temperature is 600°C, heat preservation for 10 hours; then cool to room temperature;

[0038] (4) Take out the cooled coal gangue powder, weigh it, and put it into a heat-resistant glass container;

[0039] (5) Prepare 10% hydrochloric acid aqueous solution;

[0040] (6) Use a measuring cup to measure the hydrochloric acid aqueous solution, the amount to be measured is...

Embodiment 2

[0049] Example 2: Press figure 1 As shown, the production raw materials and proportions:

[0050] Coal gangue: 100%.

[0051] The preparation method of artificial red agate is:

[0052] (1) Weigh a certain weight of coal gangue;

[0053] (2) Crushing and grinding massive coal gangue raw materials;

[0054] (3) Put the coal gangue that has been ground into powder into a heat treatment furnace for heating to remove moisture and organic matter in the gangue. The feature is: put the coal gangue powder into a crucible, put it into the heat treatment furnace at room temperature, and heat up with the furnace; The temperature is 800°C, heat preservation for 8 hours; then cool to room temperature;

[0055] (4) Take out the cooled coal gangue powder, weigh it, and put it into a heat-resistant glass container;

[0056] (5) Prepare 10% hydrochloric acid aqueous solution;

[0057] (6) Use a measuring cup to measure the hydrochloric acid aqueous solution, and the quantity to be measur...

Embodiment 3

[0066] Embodiment 3: press figure 1 As shown, the production raw materials and proportions:

[0067] Coal gangue: 100%.

[0068] The preparation method of artificial red agate is:

[0069] (1) Weigh a certain weight of coal gangue;

[0070] (2) Crushing and grinding massive coal gangue raw materials;

[0071] (3) Put the coal gangue that has been ground into powder into a heat treatment furnace for heating to remove moisture and organic matter in the gangue. The feature is: put the coal gangue powder into a crucible, put it into the heat treatment furnace at room temperature, and heat up with the furnace; The temperature is 900°C, heat preservation for 6 hours; then cool to room temperature;

[0072] (4) Take out the cooled coal gangue powder, weigh it, and put it into a heat-resistant glass container;

[0073] (5) Prepare 10% hydrochloric acid aqueous solution;

[0074] (6) Use a measuring cup to measure the hydrochloric acid aqueous solution, and the amount to be measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com