Antibacterial water treatment material and preparing method thereof

An antibacterial water and chitin fiber technology, applied in the direction of sterilization/microdynamic water/sewage treatment, water/sludge/sewage treatment, special treatment targets, etc., can solve the problems of difficult recycling, water turbidity, etc., and achieve stable effect , The preparation method is simple, the effect of good sterilization and antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh 50kg of polyvinyl butyral, 6kg of chitin fibers with a diameter of 5 microns, 5kg of diisobutyl phthalate, 2kg of phenoxyethanol, 1,8-diazabicyclo (5,4, 0) 7-undecene 1kg, phthaloyl peroxide 0.8kg, 5,6,7,3',4'-pentamethoxyflavone 0.5kg, zinc borate 0.5kg, ammonium oxalate 0.2kg, aluminum sulfate 0.2kg and perillaldehyde 0.08kg, pulverized and finely ground at 100°C for 10 minutes;

[0027] (2) Put into a high-pressure homogenizer and mix for 10 minutes at 70° C. and 20 MPa, adjust the pH to 7.8, and cool to room temperature to obtain an antibacterial water treatment material.

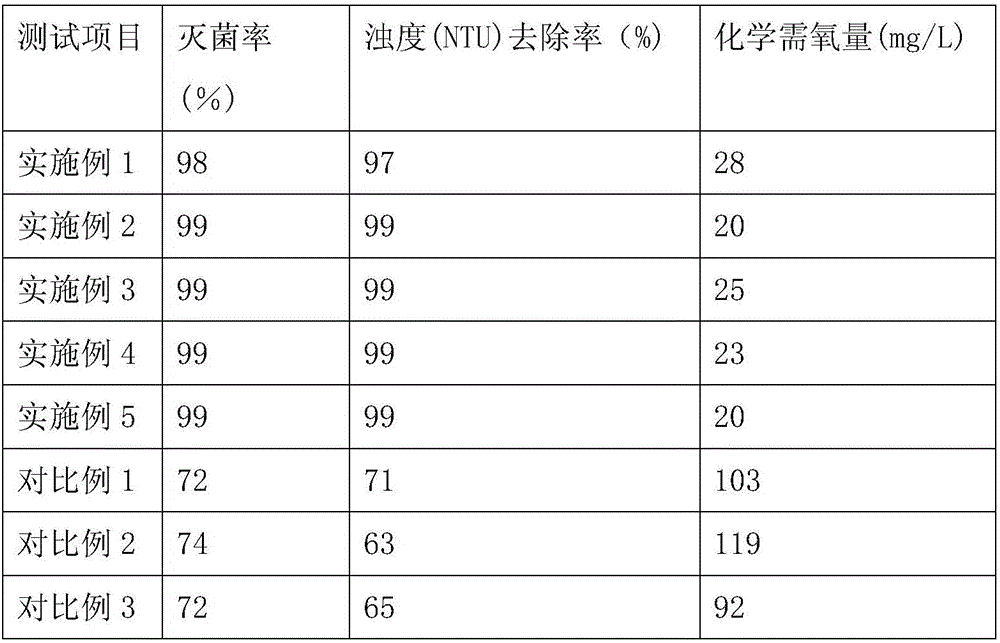

[0028] The performance test results of the prepared antibacterial water treatment materials are shown in Table 1.

Embodiment 2

[0030] (1) Weigh 50kg of polyvinyl butyral, 6kg of chitin fibers with a diameter of 5 microns, 5kg of diisobutyl phthalate, 2kg of phenoxyethanol, 1,8-diazabicyclo (5,4, 0) 7-undecene 1kg, phthaloyl peroxide 0.8kg, 5,6,7,3',4'-pentamethoxyflavone 0.5kg, zinc borate 0.5kg, ammonium oxalate 0.2kg, aluminum sulfate 0.2kg, perillaldehyde 0.08kg and sodium polyacrylate 1kg, pulverized and finely ground at 100°C for 10 minutes;

[0031] (2) Put into a high-pressure homogenizer and mix for 10 minutes at 70° C. and 20 MPa, adjust the pH to 7.8, and cool to room temperature to obtain an antibacterial water treatment material.

[0032] The performance test results of the prepared antibacterial water treatment materials are shown in Table 1.

Embodiment 3

[0034] (1) Weigh 58kg of polyvinyl butyral, 9kg of chitin fibers with a diameter of 15 microns, 7kg of diisobutyl phthalate, 3kg of phenoxyethanol, 1,8-diazabicyclo (5,4, 0) 7-undecene 2kg, phthaloyl peroxide 1kg, 5,6,7,3',4'-pentamethoxyflavone 1kg, zinc borate 0.8kg, ammonium oxalate 0.5kg, aluminum sulfate 0.3kg , 0.5kg of perillaldehyde and 1kg of sodium polyacrylate, pulverized and finely ground at 120°C for 20 minutes;

[0035] (2) Put it into a high-pressure homogenizer and mix at 85° C. and 22 MPa for 20 minutes, adjust the pH to 8.2, and cool to room temperature to obtain an antibacterial water treatment material.

[0036] The performance test results of the prepared antibacterial water treatment materials are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com