Amine oligomer anti-oxidant and preparation method thereof

A technology of oligomers and antioxidants, applied in additives, lubricating compositions, petroleum industry, etc., can solve the problems of weak antioxidant performance, poor solubility, low thermal decomposition temperature, etc., and achieve excellent oxidation resistance, good The effect of solubility and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

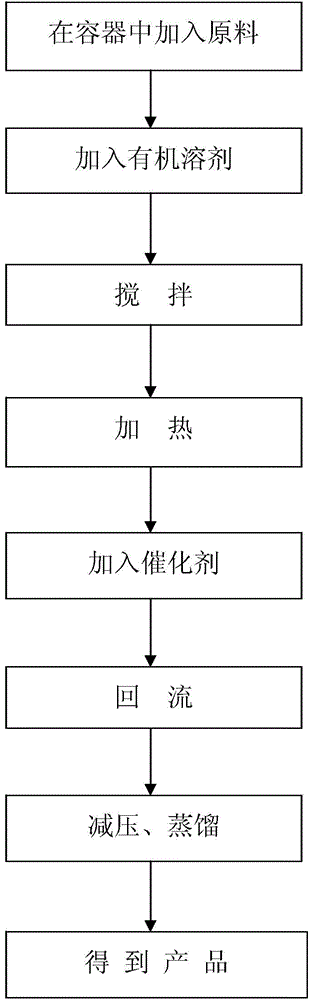

[0071] In a 500ml four-necked flask equipped with a reflux condenser and a thermometer, add 0.1mol of dioctyldiphenylamine and 0.1mol of butyloctyldiphenylamine, then add 100ml of petroleum ether as a solvent, and add 0.1mol of Peracetic acid and 0.1mol of potassium permanganate, the reaction temperature is between 65-70 ° C, reflux for 9 hours, after the reaction, dilute the product with a diluent, wash with water until neutral, and then distill under reduced pressure to obtain a brown-gray solid product.

Embodiment 2

[0073] Add 0.1mol of octyl N-phenyl-α-naphthylamine and 0.1mol of butyloctyldiphenylamine in a 500ml four-neck flask equipped with a reflux condenser and a thermometer, then add 100ml of sherwood oil as a solvent, and stir Add 0.1 mol of peracetic acid and 0.1 mol of potassium permanganate under the condition, the reaction temperature is between 65-70 ℃, reflux reaction for 6 hours, after the reaction, dilute the product with diluent, wash with water until neutral, then reduce Pressure distillation gives a brown semi-flowing liquid product.

[0074] Test results such as figure 1 and figure 2 Shown:

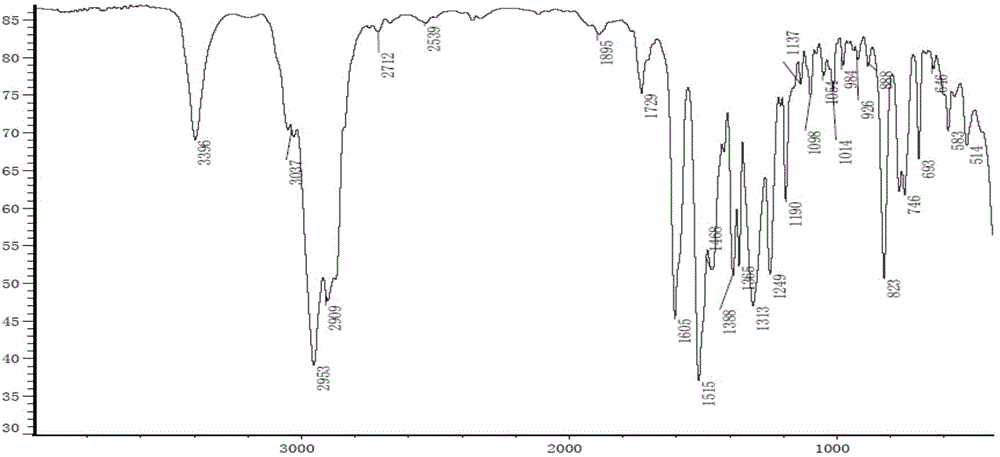

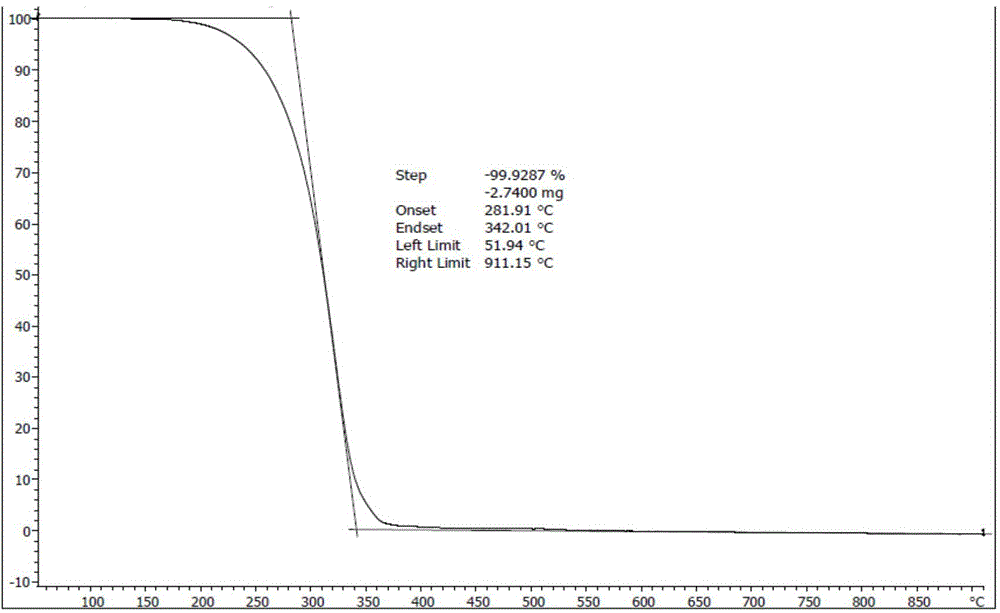

[0075] figure 1 Be that example 2 obtains the infrared spectrogram of amine oligomer antioxidant. Among them, the weak absorption peak at 1054cm-1 is the absorption peak of -N-N- bond, near 1605cm-1 is the in-plane vibration peak of -C=C- in the benzene ring, and near 2953 and 2909cm-1 is the C-H bond on the benzene ring Stretching vibration peak, near 3396cm-1 may be the vi...

Embodiment 3

[0078] Add 0.2mol alkyl N-phenyl-α-naphthylamine in the 500ml four-neck flask that reflux condenser and thermometer are housed, then add 100ml sherwood oil as solvent, add the peracetic acid of 0.11mol under the condition of stirring, The reaction temperature is between 65-70°C, and the reaction is carried out under reflux for 8 hours. After the reaction, the product is diluted with a diluent, washed with water until neutral, and then distilled under reduced pressure to obtain a dark brown solid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com