Water-sensitive fluorescent capillary tube based on amino silanization zinc oxide as well as preparation method and application of water-sensitive fluorescent capillary tube

An amino silanization and capillary technology, which is applied in chemical instruments and methods, fluorescence/phosphorescence, luminescent materials, etc., can solve the problems of insensitive end points, high environmental requirements, and large measurement errors, and achieves intuitive quantitative methods and safe reagents. The effect of portability of the virus and detection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

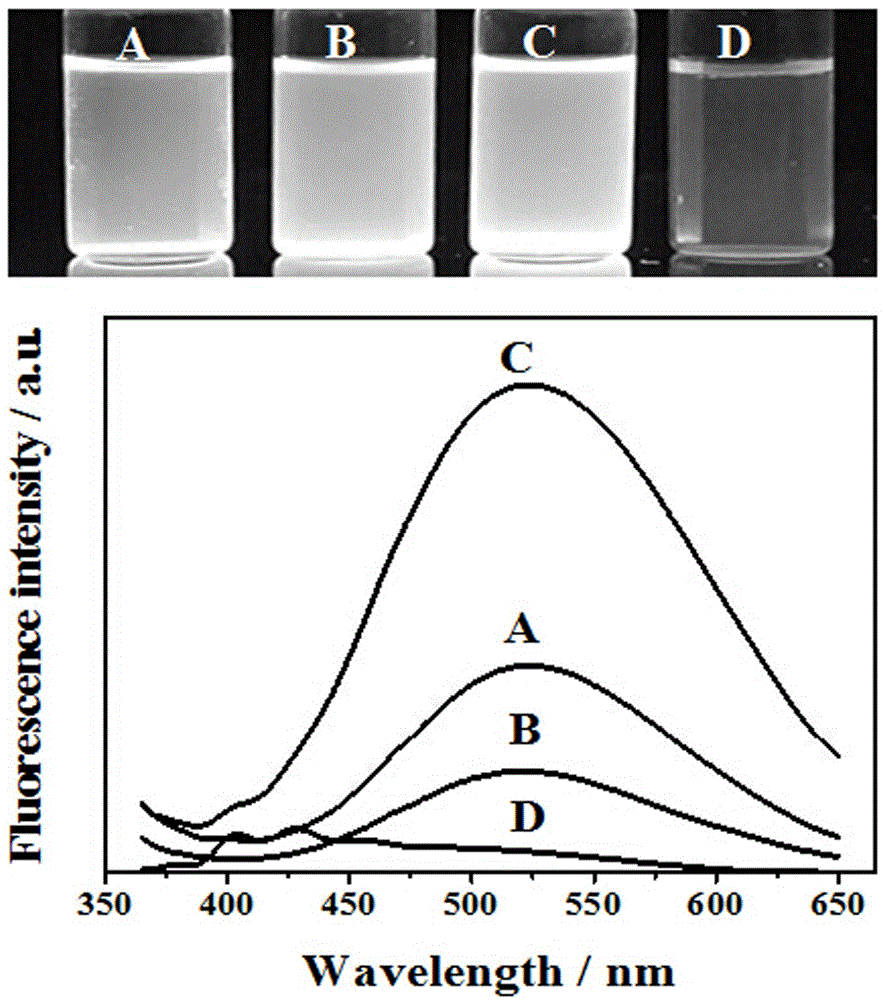

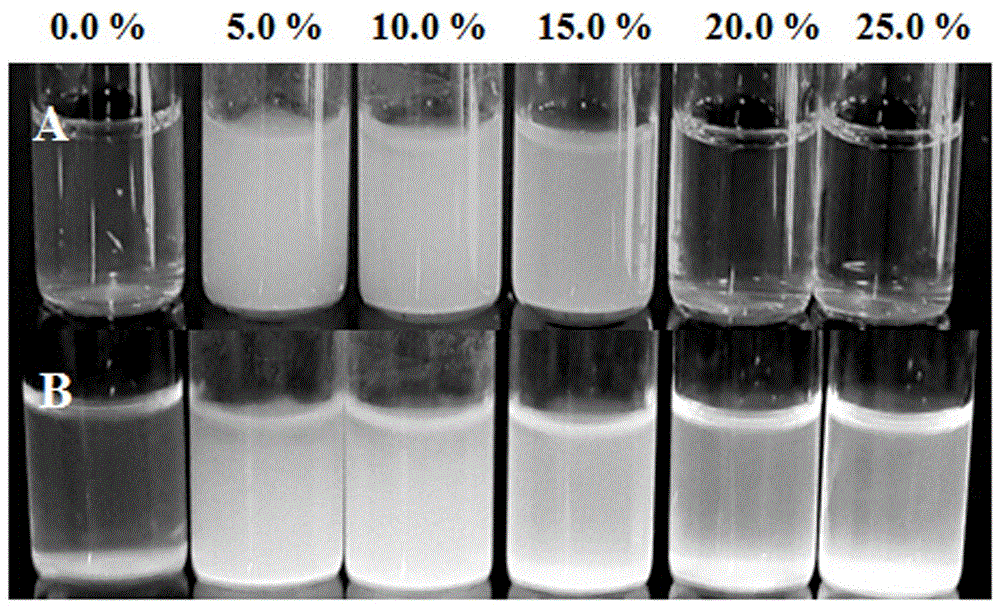

[0037] A water-sensitive fluorescent capillary based on aminosilanized nano-zinc oxide, which is composed of capillary and aminosilanized nano-zinc oxide (APS-ZnO) cured on the inner surface of the capillary, and the loading of APS-ZnO on the inner surface of the capillary is 0.03mg / mm 2 ; The APS-ZnO is a colorless transparent sol.

[0038] The capillary is a colorless and transparent glass capillary with openings at both ends, with an inner diameter of 1.0 mm, a thickness of 0.08 mm, and a length of 10.0 cm.

[0039] The water-sensitive fluorescent capillary based on aminosilanized nano zinc oxide has a colorless and transparent initial color and a size of about 3 nm.

[0040] The preparation method comprises the following steps:

[0041] 1) Preparation of fluorescent APS-ZnO water-sensitive nanosol: Zn(AC) 2 2H 2 O was dissolved in absolute ethanol at a concentration of 0.066 g / mL, sonicated at room temperature for 10 min, and then LiOH·H 2 O, Zn(AC) 2 2H 2 O and Li...

Embodiment 2

[0045] 1) Preparation of fluorescent APS-ZnO water-sensitive nanosol: Zn(AC) 2 2H 2 O was dissolved in absolute ethanol at a concentration of 0.033 g / mL, sonicated at room temperature for 10 min, and then LiOH·H 2 O, Zn(AC) 2 2H 2 O and LiOH·H 2 The ratio of the amount of O to the substance is 1.0, continue to sonicate until it is completely dissolved, and obtain a nano-zinc oxide material. The concentration of zinc oxide in the nano-zinc oxide material is 0.050mol / L, and then add 3-aminopropyl three Ethoxysilane, the ratio of 3-aminopropyltriethoxysilane to the amount of zinc oxide in the nano-zinc oxide material is 1:40, sealed, protected from light, stirred overnight at room temperature, to obtain fluorescent APS-ZnO water sensitive nano sol;

[0046] 2) Hydrophobic treatment of the capillary: Soak the capillary matrix material in a mixed solution of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 7:3 for 12 hours, wash off the excess acid on th...

Embodiment 3

[0049] 1) Preparation of fluorescent APS-ZnO water-sensitive nanosol: Zn(AC) 2 2H 2 O was dissolved in absolute ethanol at a concentration of 0.011g / mL, sonicated at room temperature for 10min, and then LiOH·H 2 O, Zn(AC) 2 2H 2 O and LiOH·H 2 The ratio of the amount of O to the substance is 1.4, continue to sonicate until it is completely dissolved, and obtain a nano-zinc oxide material. Ethoxysilane, the ratio of 3-aminopropyltriethoxysilane to the amount of zinc oxide in the nano-zinc oxide material is 1:60, sealed, protected from light, stirred overnight at room temperature, to obtain fluorescent APS-ZnO water-sensitive nano sol;

[0050] 2) Hydrophobic treatment of the capillary: Soak the capillary matrix material in a mixed solution of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 7:3 for 12 hours, wash off the excess acid on the surface with water, and introduce hydroxyl groups on the surface. After drying, soak in sixteen In the ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com