Low-temperature poly-crystal thin film transistor and preparation method thereof

A thin-film transistor and low-temperature polysilicon technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of increasing process complexity, high manufacturing cost, low production efficiency, etc. The effect of reducing the requirements for pulse energy stability and beam fluence uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

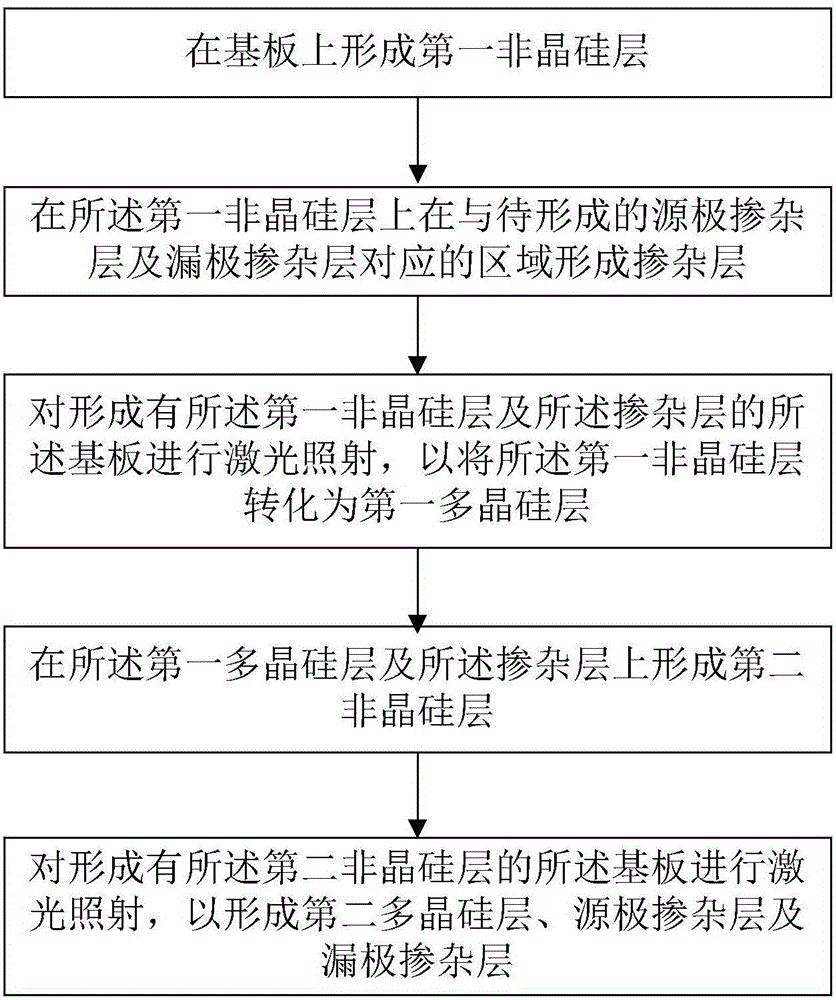

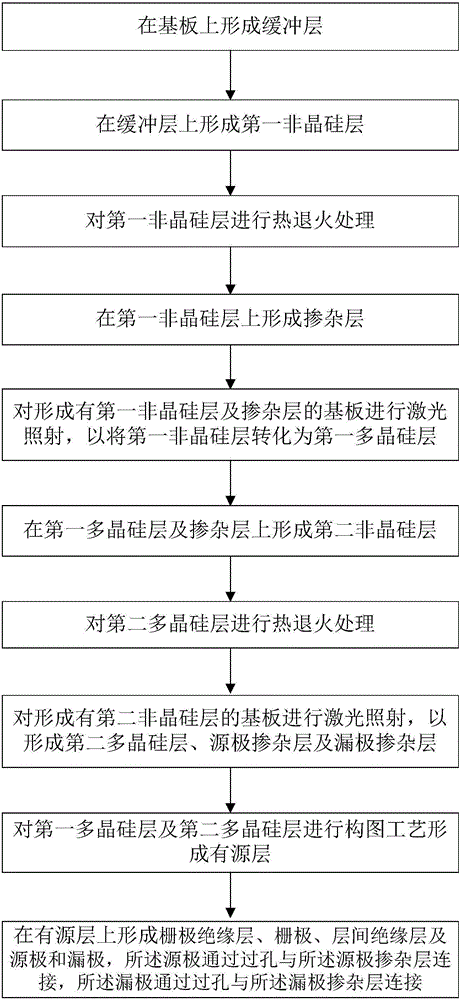

[0036] see figure 1 , which is a method for preparing a low-temperature polysilicon thin film transistor according to an embodiment of the present invention, comprising the following steps:

[0037] S110, forming a first amorphous silicon layer on the substrate;

[0038] Specifically, the thickness of the first amorphous silicon layer is 10-20 nm. Preferably, the thickness of the first amorphous silicon layer is 15 nm.

[0039] S120, forming a doped layer on the first amorphous silicon layer in regions corresponding to the to-be-formed source doped layer and drain doped layer;

[0040] In an embodiment of the present invention, a phosphorus-containing structural layer or a boron-containing structural layer is formed on the first amorphous silicon layer; a patterning process is performed on the phosphorus-containing structural layer or boron-containing structural layer, and the first amorphous silicon layer is retained. The phosphorus-containing structure layer or the boron-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com