AlGaInP light-emitting diode

A technology of light-emitting diodes and light-emitting layers, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of inability to meet market demand, deterioration of anti-aging performance under high current, etc., to improve current expansion, improve aging performance, and improve reliability. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

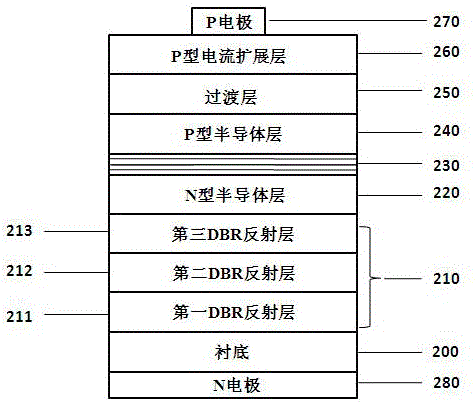

[0037] Such as figure 2As shown, this embodiment provides an AlGaInP light-emitting diode, including the following process steps: using metal organic chemical vapor deposition (MOCVD) to sequentially epitaxially grow a first DBR reflective layer 211, a second DBR reflective layer 212, and a second DBR reflective layer 212 on a substrate 200. Three DBR reflective layer 213 , N-type semiconductor layer 220 , quantum well light-emitting layer 230 , P-type semiconductor layer 240 , transition layer 250 and P-type current spreading layer 260 .

[0038] The manufacturing process of the AlGaInP light-emitting diode described in the present invention uses high-purity hydrogen (H2) as the carrier gas, trimethylgallium (TMGa), trimethylaluminum (TMAl), trimethylindium (TMIn), arsine ( AsH3), phosphine (PH3) are respectively used as sources of Ga, Al, In, As, and P, and silane (Si2H6) and dimagnesium (Cp2Mg) are used as N and P-type dopants respectively. The specific method is describe...

Embodiment 2

[0050] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that the doping concentration of the multispectral DBR is increased, and the doping concentration of the three-stage DBR is increased by 20% respectively. That is: the doping concentration of the first DBR reflective layer 211 is 2.4×10 19 cm -3 , the doping concentration of the second DBR reflective layer 212 is 1.2×10 19 cm -3 , the doping concentration of the third DBR reflective layer 213 is 7.2×10 18 cm -3 , and the rest of the structure remains unchanged.

[0051] The new AlGaInP structure LED, after preparing the P-type electrode 270 and the N-type electrode 280, is evaluated with a small-sized chip of 5.8mil*5.8mil. At 100mA and a high temperature of 50°C, the long-term aging light decay value can be controlled at minus 5%. within. It can be seen that by increasing the DBR doping concentration, the high current resistance performance of small-sized chips can be significant...

Embodiment 3

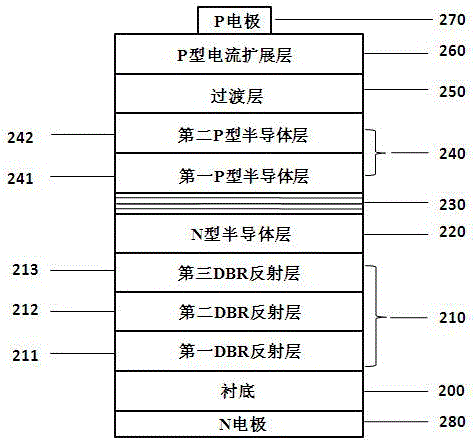

[0053] The difference between Embodiment 3 and Embodiment 2 lies in that on the basis of Embodiment 2, the doping concentration of the second P-type semiconductor layer adjacent to the transition layer is reduced to prepare a segmented doped P-type semiconductor layer. Such as image 3 As shown, grow a P-type semiconductor layer on the 230 quantum well light-emitting layer, preferably Al x In (1-x) p. The growth temperature was adjusted to 670 degrees, the pressure of the reaction chamber was set to 60 Torr, and Mg was selected for doping. When growing the first P-type semiconductor layer 241 adjacent to the quantum well light-emitting layer, Cp2Mg needs to be introduced, and the flow setting should be kept constant for 10 minutes, with a doping concentration of 1.0×10 18 cm -3 , the growth thickness is about 0.5 μm. Next, when growing the second P-type semiconductor layer 242 adjacent to the transition layer, it is necessary to use a 1min gradual change method to reduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com