A membrane electrode with double metal layer anode for electrolysis of water and preparation method thereof

A bimetallic layer and membrane electrode technology, applied in the field of electrochemistry, can solve problems such as low electrolysis efficiency, insufficient binding force, and reduced stability of electrolyzed water devices, and achieve advanced preparation technology, solve weak bonding, and excellent stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

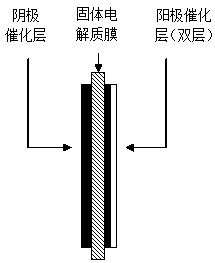

[0039] A membrane electrode with a double metal layer anode and a preparation method thereof comprise the following steps:

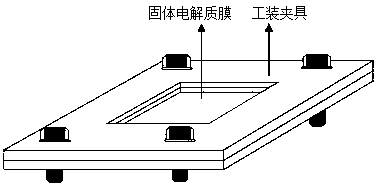

[0040] 1) Soak the solid polymer membrane (Nafion proton exchange membrane) with pure water, take it out and blot the surface water, cut out the required size with a die cutter, and use the hollow special tooling fixture of the present invention (see attached figure 1 ) are clamped to form a cavity on both sides of the solid polymer film for the exchange deposition of the catalytic layer;

[0041] 2) Take a certain concentration of Pt(NH 3 ) 4 Cl 2 Or other solutions containing platinum ions, added to the cavity on the side intended to be the anode, to exchange the platinum ions with the hydrogen ions on the surface of the solid polymer membrane. The exchange time is 1-3 hours. In order to ensure the exchange effect, the solution can also be replaced Perform 2 to 3 exchanges; to ensure that a sufficient amount of platinum ions are exchanged to the sur...

Embodiment 1

[0047] Nafion115 membrane (DuPont, USA, thickness 127 microns)) soaked in pure water for 3 hours, took out and blotted the surface water, then cut out a 60cm×60cm square piece, carefully placed the cut solid polymer membrane in a special tooling mold, such as figure 1 The cavity area of the mold shown is 50×50cm, which is composed of two symmetrical splints up and down and fastened with screws. Add 25g / L of Pt(NH 3 ) 4 Cl 2 Solution 25ml, standing exchange 3h at room temperature, then reclaim Pt(NH 3 ) 4 Cl 2 Solution, replaced with a new solution for another 3 hours to ensure sufficient exchange of hydrogen protons and platinum ions on the surface of the solid polymer membrane. After the exchange is complete, remove the platinum-containing solution and add 0.01mol / L NaBH 4 Solution 20ml, reduction reaction at room temperature for 30 minutes, the platinum particles exchanged to the surface of the solid polymer film are reduced to form a uniform and dense bright platin...

Embodiment 2

[0056] Except that the preparation of the iridium catalyst layer is different from Example 1, other steps are the same as Example 1.

[0057] The iridium catalyst layer is prepared by electrodeposition.

[0058] The formula of electrodeposition solution is: ammonium chloroiridate 10g / L, boric acid 40g / L, sodium malonate 2g / L;

[0059] The platinum catalyst layer deposited on the proton exchange membrane is used as the cathode, and the platinum sheet is used as the anode, at 85°C, the deposition current density is 2mA / cm 2 Deposition for 6 hours; the amount of iridium deposition is 0.3mg / cm 2 .

[0060] Electrolyzed water test at 70°C with a current density of 500mA / cm 2 , the cell voltage is 1.60V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com