Device and method for treating waste gas containing high-and medium-concentration benzene

A treatment method and technology of treatment device, which are applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of low technical efficiency, high cost, secondary pollution, etc., and achieve obvious economic benefits, reduce air resistance, waste gas and other problems. Deal with thorough effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

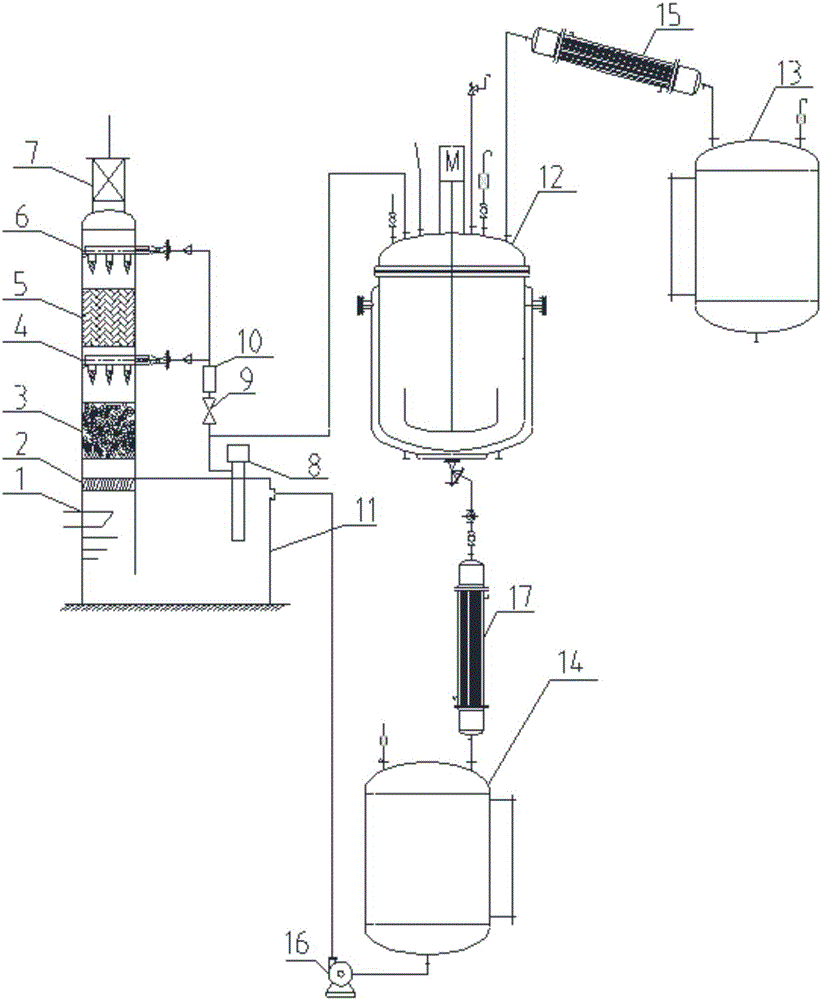

[0031] A complete set of treatment equipment for waste gas containing medium and high concentrations of benzene, such as figure 1As shown, it includes an air distribution system, an absorption system and a circulation system; the air distribution system is provided with an air inlet 1 and a grille air distribution net 2, and the grille air distribution net 2 is installed above the air inlet 1; the absorption system is arranged from bottom to top Set random packing 3, first-level sprinkler head 4, structured packing 5, second-level sprinkler head 6, and mist eliminator 7, wherein first-level sprinkler head 4 is installed on random packing 3, and structured packing 5 is installed on The first-level spray head 4 is installed on the second-level spray head 6, and the second-level spray head 6 is installed on the structured packing 5, and finally the entrained absorption liquid is removed through the demister 7; the circulation system is equipped with a submerged pump 8, an absorpti...

Embodiment 2

[0038] The intake concentration of benzene exhaust gas is 40g / m 3 , The absorbent A used is 1,4 butanediol (BDO). The exhaust gas enters from the bottom of the absorption tower, and passes through the grid gas distribution area, random packing, structured packing and demister in sequence. The empty tower coefficient of the spray tower is 4m 3 / (m 2 , h), the spray density is 0.8m / s, the height-to-diameter ratio of random packing is 1.8, and the height-to-diameter ratio of structured packing is 0.8; the removal rate of benzene reaches more than 99%.

[0039] The saturated solvent A is desorbed in the desorption tank, and the 80°C fraction is taken separately to obtain benzene with a product purity of 95%. The desorbed 1,4-butanediol (BDO) is recycled for spray absorption.

Embodiment 3

[0041] Containing toluene waste gas inlet concentration is 18g / m 3 , The absorbent A used is sulfolane. The waste gas enters from the bottom of the absorption tower, and passes through the grid gas distribution area, random packing, structured packing and demister in sequence, among which, the empty tower coefficient of the spray tower is 5m 3 / (m 2 , h), the spray density is 1.5m / s, the ratio of random packing height to tower diameter is 1.5, and the ratio of structured packing height to tower diameter is 1.5; the removal rate of toluene reaches 97%.

[0042] The saturated solvent A is desorbed in the desorption kettle, and the 111°C fraction is taken separately to obtain toluene with a product purity of 94%. The desorbed sulfolane is recycled for spray absorption.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com