A kind of preparation method of synthetic phospholipid DPPC

A technology for synthesizing phospholipids and palmitoyl phosphatidyl choline, which is applied in the field of medicine and chemical industry, can solve the problems of cumbersome post-processing process, high toxicity of reaction solvent, serious environmental pollution, etc., and achieves the advantages of cheap raw materials, easy industrial production and high economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

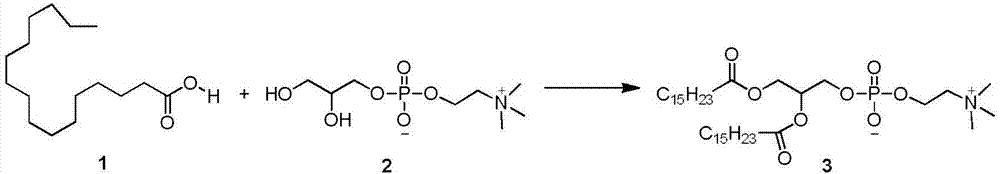

Method used

Image

Examples

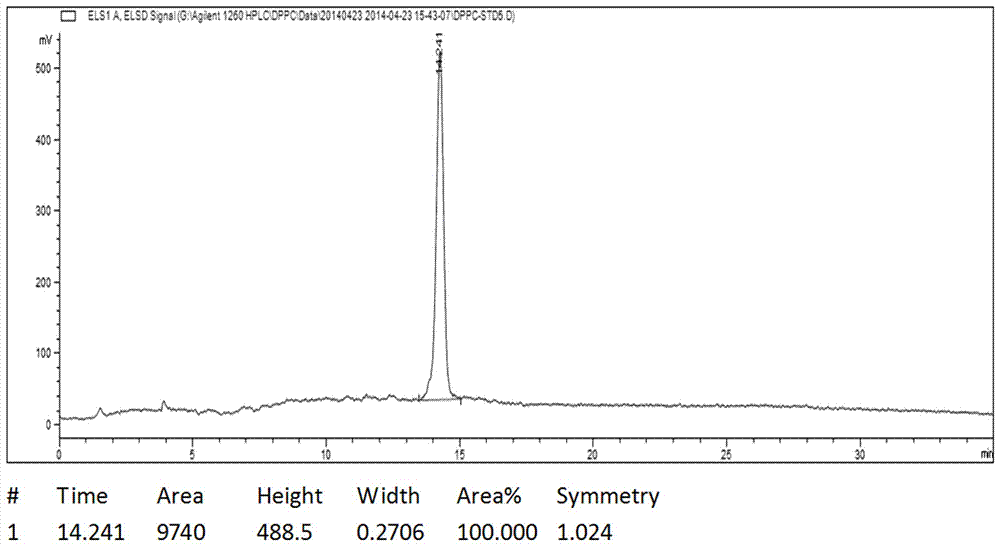

Embodiment 1

[0029] Add 50g glycerylphosphonocholine, 200g palmitic acid, 95g DMAP, and 1000mL chloroform to a clean and dry 2000mL three-necked flask. Stir evenly with magnetic force, and protect with argon replacement. Dissolve 165 g of DCC with 1000 mL of chloroform, and quickly drop the DCC chloroform solution into the reaction system. Avoid light and react at 20°C for 5h. During the reaction process, a large amount of white insoluble solids appeared, and the reaction was stopped if no further progress was detected by TLC. The reaction solution was filtered to remove the white insoluble solid DCU to obtain a bright yellow transparent liquid, which was evaporated to dryness to obtain a yellow viscous liquid, which was beaten with 3000 mL of acetone for 10 h, and a large amount of white solids were precipitated in the system. The catalyst 4-dimethylaminopyridine (DMAP) in the system was removed by filtration. Repeat once, filter off-white solid, and dry to obtain crude product 130g. ...

Embodiment 2

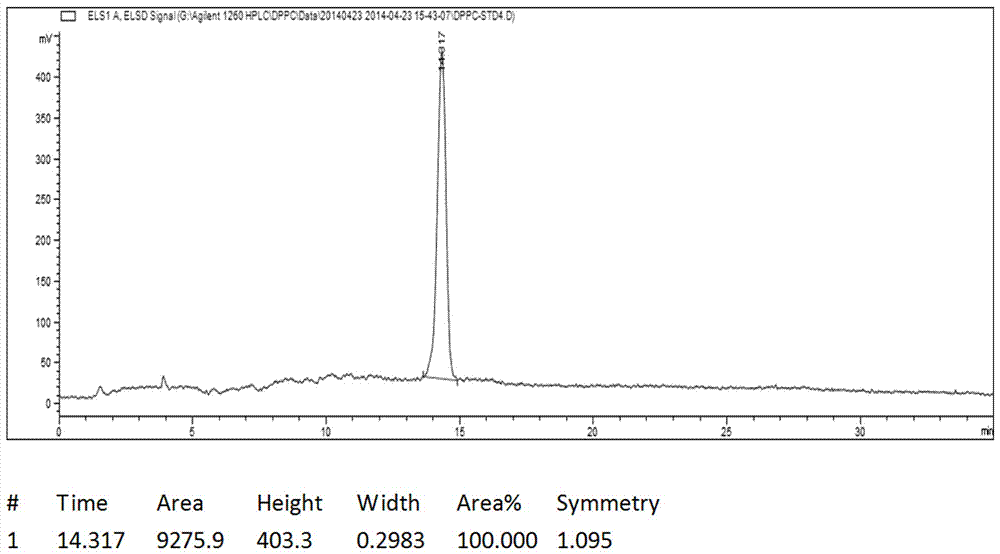

[0033] Add 5g glycerylphosphonocholine, 20g palmitic acid, 9.5g TEA, and 50mL chloroform into a clean and dry 200mL three-necked flask. Stir evenly with magnetic force, and protect with argon replacement. 16.5 g of DCC was dissolved in 200 mL of chloroform, and the DCC chloroform solution was quickly dropped into the reaction system. Protect from light and react below 20°C for 1d. During the reaction process, a large amount of white insoluble solids appeared, and the reaction was stopped if no further progress was detected by TLC. The reaction solution was filtered to remove the white insoluble solid DCU to obtain a bright yellow transparent liquid, which was evaporated to dryness to obtain a yellow viscous liquid, which was beaten with 300 mL of acetone for 10 hours, and a large amount of white solid was precipitated in the system, filtered to obtain an off-white solid, and dried to obtain Crude product 13g. Heat the crude product with 200mL of dichloromethane at 50°C with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com