Refining method for tedizolid phosphate

A technology of tedizolid phosphate and tedizolid phosphate disodium salt, which is applied in the field of refining tedizolid phosphate, and can solve problems such as low flash point and difficult removal of gel and ether

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

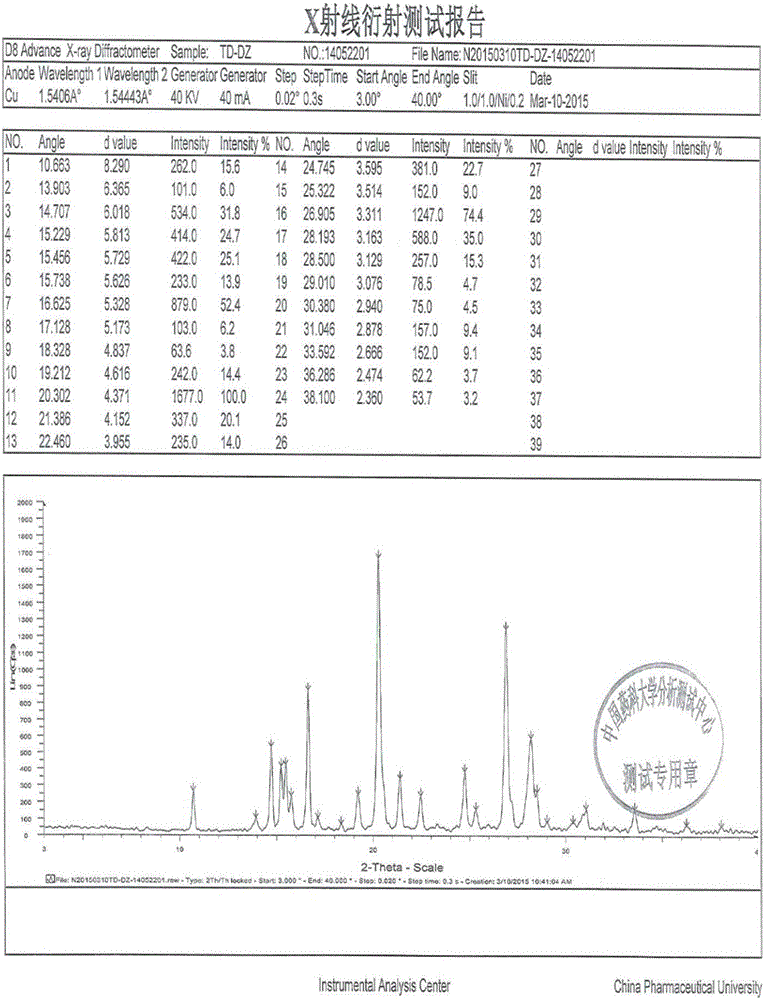

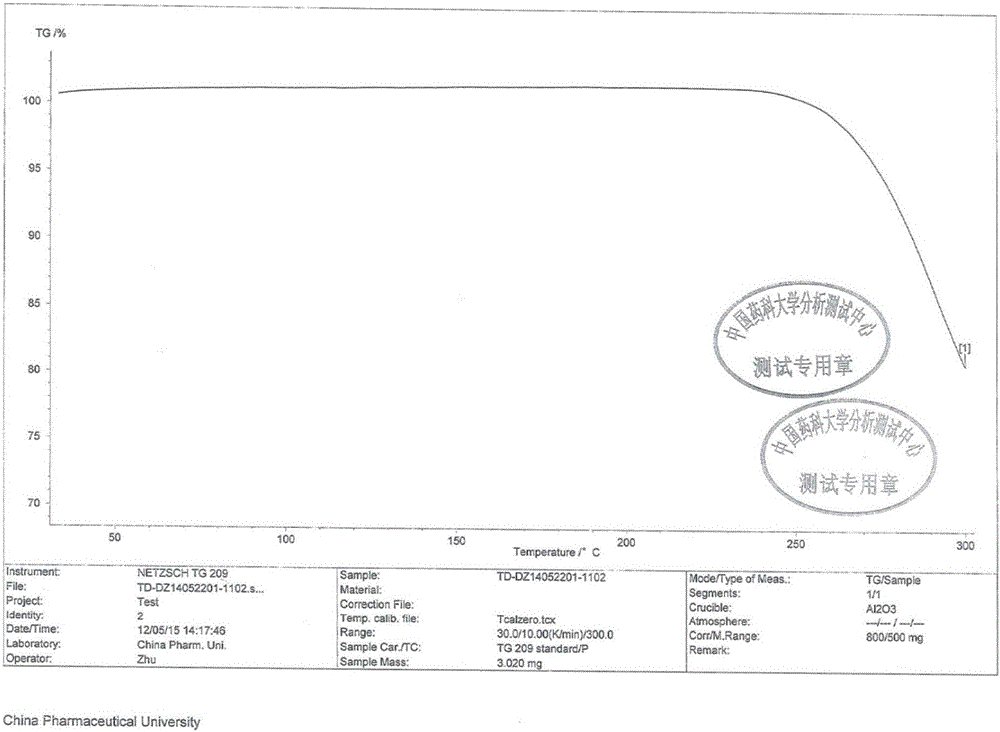

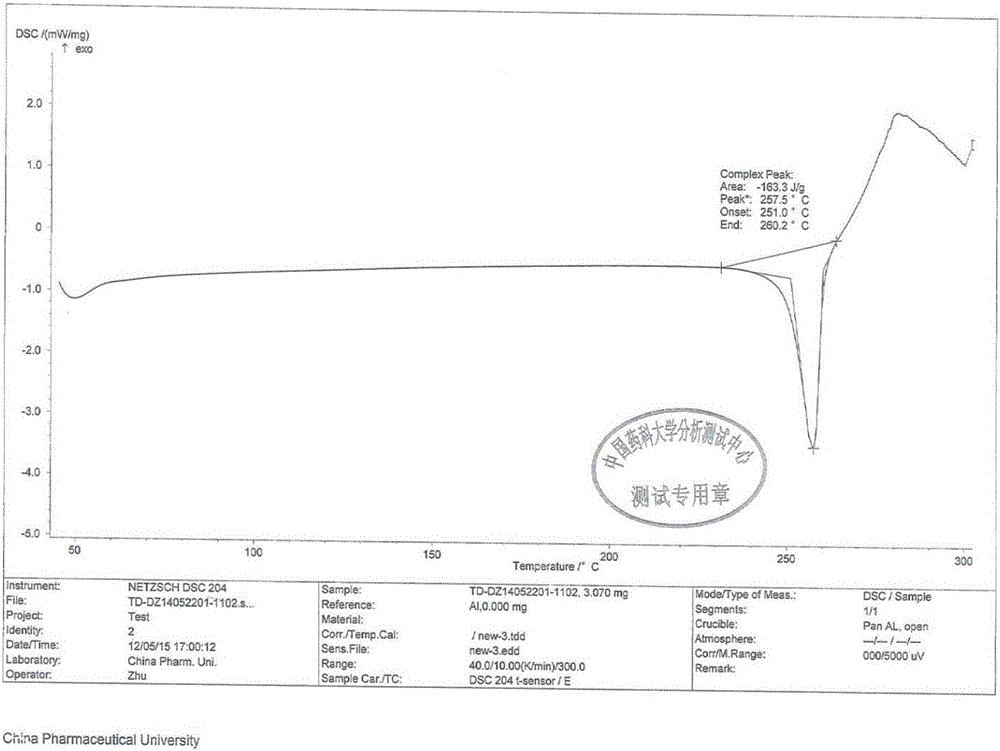

Image

Examples

Embodiment 1

[0060] Dissolve 45g of tedizolid phosphate in purified water (185ml), add dropwise 8% sodium hydroxide solution at an internal temperature of 15-25°C, adjust the pH to 7.5, add activated carbon (2.25g), and control the internal temperature at 15-25°C. Stir at 25°C for 2 hours, filter, transfer the filtrate to a reaction flask, slowly add acetone (1.73L), stir and analyze for 2 hours, a large amount of solid precipitates, filter, wash the filter cake with a small amount of acetone, and drain to obtain tedizolid phosphate sodium salt .

[0061] The tedizolid phosphate sodium salt obtained above was transferred to a reaction flask, and purified water (185 ml) was added to dissolve it. 3% hydrochloric acid solution (365ml) was added dropwise at an internal temperature of 15-25°C. After the dropwise addition was complete, the mixture was stirred at the same temperature for 1h, and then acetonitrile (890ml) was slowly added. Stir and crystallize at 15-25°C for 3h, stirring at 200r....

Embodiment 2

[0063] Dissolve 30g of tedizolid phosphate in purified water (180ml), add 10% sodium hydroxide solution dropwise at an internal temperature of 5-10°C, adjust the pH to 7.2, add activated carbon (3.0g), and control the internal temperature at 20-10°C. Stir at 25°C for 1 hour, filter, transfer the filtrate to a reaction flask, add acetone (760ml) slowly, stir and analyze for 3 hours, a large amount of solid precipitates, filter, wash the filter cake with a small amount of acetone, and drain to obtain tedizolid phosphate sodium salt.

[0064] The tedizolid phosphate sodium salt obtained above was transferred to a reaction flask, and purified water (180 ml) was added to dissolve it. 5% hydrochloric acid solution (365ml) was added dropwise at an internal temperature controlled at 5-10°C. After the dropwise addition was complete, the mixture was stirred at the same temperature for 1h, and acetonitrile (380ml) was slowly added. Stir and crystallize at 15-25°C for 5h, stirring at 230r...

Embodiment 3

[0066] Dissolve 30g of tedizolid phosphate in purified water (150ml), add 5% sodium hydroxide solution dropwise at an internal temperature of 10-15°C, adjust the pH to 7.4, add activated carbon (2.5g), and control the internal temperature at 15-15°C. Stir at 20°C for 1.5h, filter, transfer the filtrate to a reaction flask, slowly add acetone (950ml), stir and analyze for 2h, a large amount of solid precipitates, filter, wash the filter cake with a small amount of acetone, and drain to obtain tedizolid phosphate sodium salt .

[0067] The tedizolid phosphate sodium salt obtained above was transferred to a reaction flask, and purified water (150 ml) was added to dissolve it. Add 8% hydrochloric acid solution (300ml) dropwise at an internal temperature of 5-10°C. After the dropwise addition, stir at the same temperature for 2h at a stirring speed of 215r.p.m, and slowly add acetonitrile (760ml). Stir and crystallize at 5-10°C for 4 hours, filter, wash with a small amount of puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com