Flexible film random laser device adjustable in polarization degree and preparation method thereof

A random laser and flexible film technology, applied in the field of random laser, can solve the problems of narrow polarization adjustment range, unstable laser wavelength, complicated preparation process, etc., and achieve the effects of stable laser wavelength, simple structure and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

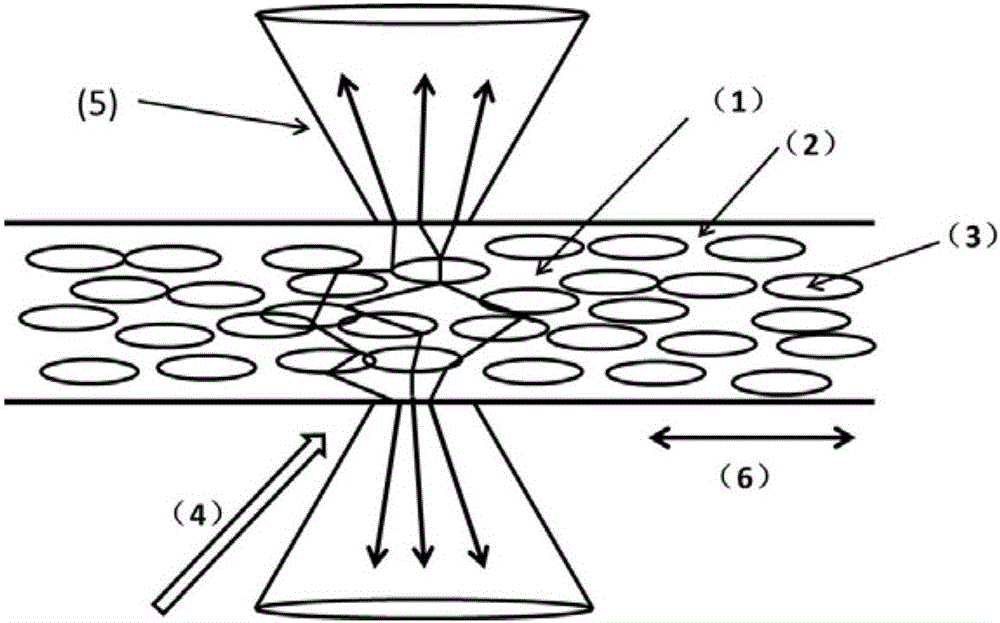

[0049] The preparation method of the above-mentioned flexible thin-film random laser with adjustable degree of polarization comprises the following steps:

[0050] a. The laser dye and the nematic liquid crystal are uniformly mixed under ultrasonic conditions to form a dye-nematic liquid crystal mixed solution;

[0051] b. Add the dye nematic liquid crystal mixed solution and polyhydric alcohol into the aqueous solution of polyvinyl alcohol, heat and stir evenly;

[0052] c. The homogeneously mixed polyvinyl alcohol aqueous solution, polyhydric alcohol, and dye nematic liquid crystal solution are prepared into an emulsion containing dye liquid crystal droplets through ultrasonic treatment;

[0053] d. performing film-forming treatment on the emulsion containing the dye liquid crystal micro-droplets, and evaporating water to obtain a polyvinyl alcohol film containing the dye liquid crystal micro-droplets.

[0054] In step b, the heating temperature is 50°, and the stirring tim...

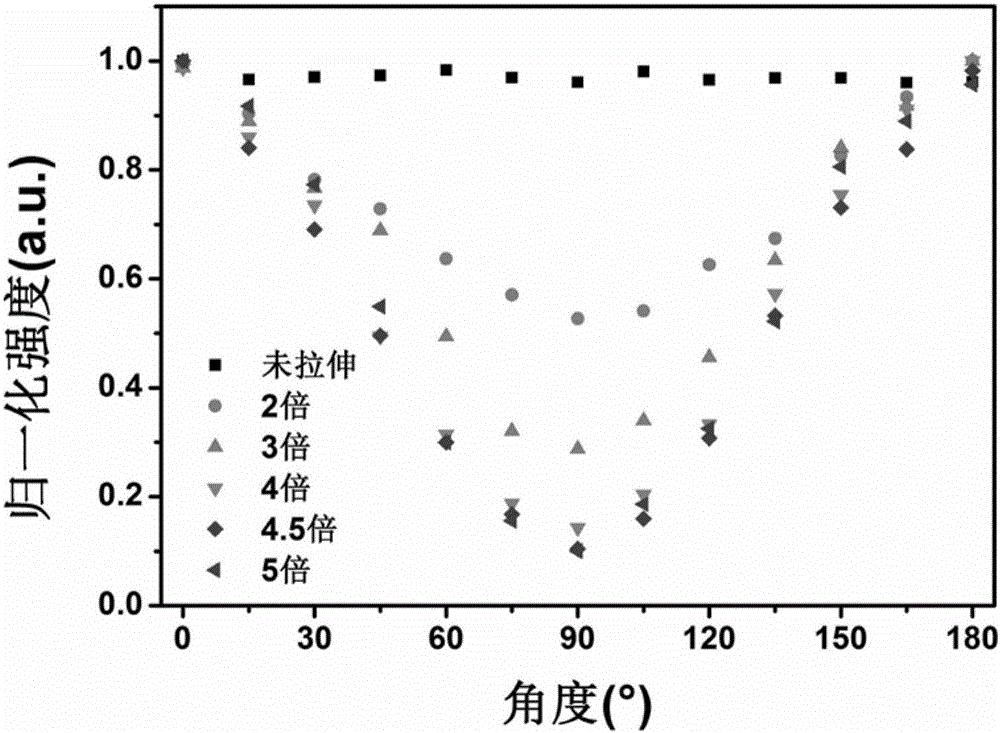

Embodiment 1

[0058] A polarization-tunable flexible thin-film random laser containing polyvinyl alcohol (n p =1.49), glycerin, laser dye PM597, nematic liquid crystal E7 (n e = 1.75, n o = 1.52). Concrete preparation process is as follows:

[0059] (1) The laser dye PM597 is ultrasonically mixed with the nematic liquid crystal E7, wherein the laser dye PM597 accounts for 1wt%;

[0060] (2) Add the dye liquid crystal mixed solution and glycerin to an aqueous solution containing 15wt% polyvinyl alcohol, heat to 50°, stir for 1 hour, and mix well;

[0061] (3) Utilize an ultrasonic cell breaker (power 325W, frequency 20KHz, ultrasonic 2s, interval 3s, total time 3min) to disperse the dye liquid crystal mixture to prepare a viscous emulsion containing dye liquid crystal droplets;

[0062] (4) Put the liquid crystal emulsion on the glass substrate by the wet film-making method to form a film with a length of 1cm, a width of 0.5cm, and a thickness of 40um. The film is peeled off from the gla...

Embodiment 2

[0067] A polarization-tunable flexible thin-film random laser containing polyvinyl alcohol (n p =1.49), glycerin, laser dye PM597, nematic liquid crystal E7 (n e = 1.75, n o = 1.52). Concrete preparation process is as follows:

[0068] (1) The laser dye PM597 is ultrasonically mixed with the nematic liquid crystal E7, wherein the laser dye PM597 accounts for 0.1wt%;

[0069] (2) Add the dye liquid crystal mixed solution and glycerin to an aqueous solution containing 15wt% polyvinyl alcohol, heat to 50°, stir for 1 hour, and mix well;

[0070] (3) Utilize an ultrasonic cell breaker (power 325W, frequency 20KHz, ultrasonic 2s, interval 3s, total time 3min) to disperse the dye liquid crystal mixture to prepare a viscous emulsion containing dye liquid crystal droplets;

[0071] (4) Put the liquid crystal emulsion on the glass substrate by the wet film-making method to form a film with a length of 1cm, a width of 0.5cm, and a thickness of 10um, and peel the film from the glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com