Phenol wastewater treatment method and preparation method of CuO/ZSM-5 catalyst

A technology of ZSM-5 and treatment method, which is applied in the direction of physical/chemical process catalyst, molecular sieve catalyst, water/sewage treatment, etc., can solve the problem of low mineralization degree, achieve simple and easy method, significant environmental advantages and economic advantages , Response equipment does not require high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation of CuO / ZSM-5 catalyst comprises the following steps:

[0033] (1) Adopt commercial ZSM-5 zeolite (silicon-aluminum ratio (SiO 2 / Al 2 o 3 )=18~30; relative crystallinity: Na type>85%; pore size: ), take 150mL of deionized water to dissolve 1.758g of copper nitrate (concentration is 0.0625mol / L), impregnate 5g of dried ZSM-5 powder with this solution, stir in a constant temperature water bath at 60°C for 3h to make ZSM-5 Zeolite and copper nitrate are uniformly mixed to obtain a catalyst precursor;

[0034] (2) The obtained catalyst precursor was first dried at 120°C for 12h, washed and dried with deionized water, then roasted in a muffle furnace at 500°C for 4h, and ground into powder (the same particle size as the original ZSM-5 zeolite powder). CuO / ZSM-5 catalyst (m(Cu) / m(ZSM-5)2) = 12%).

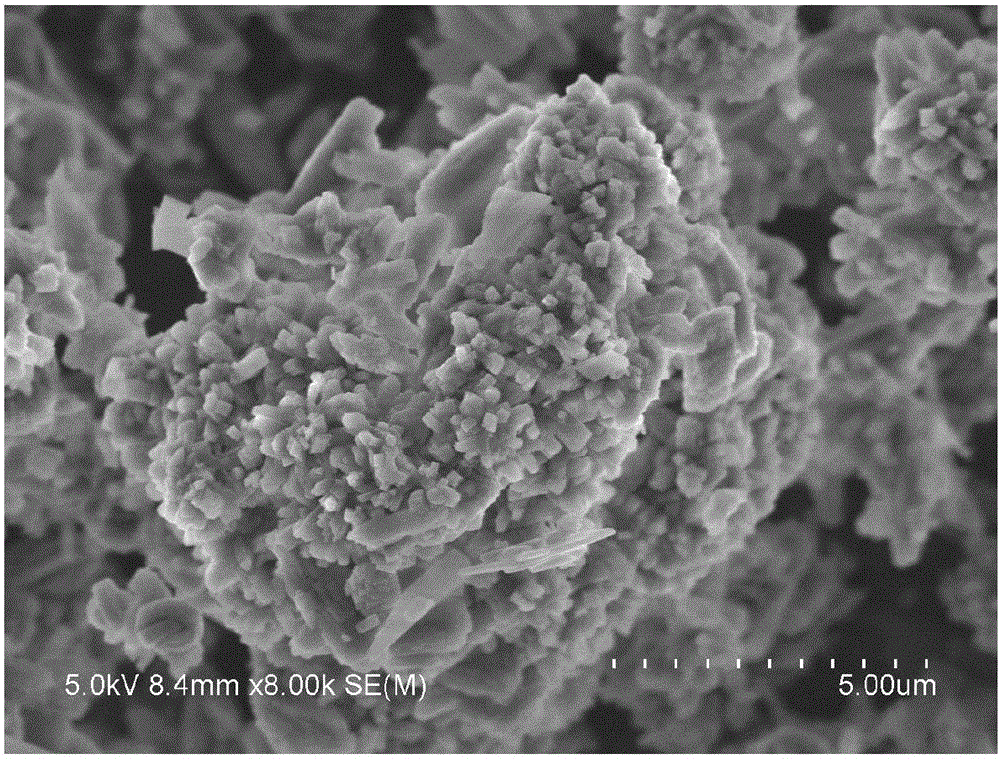

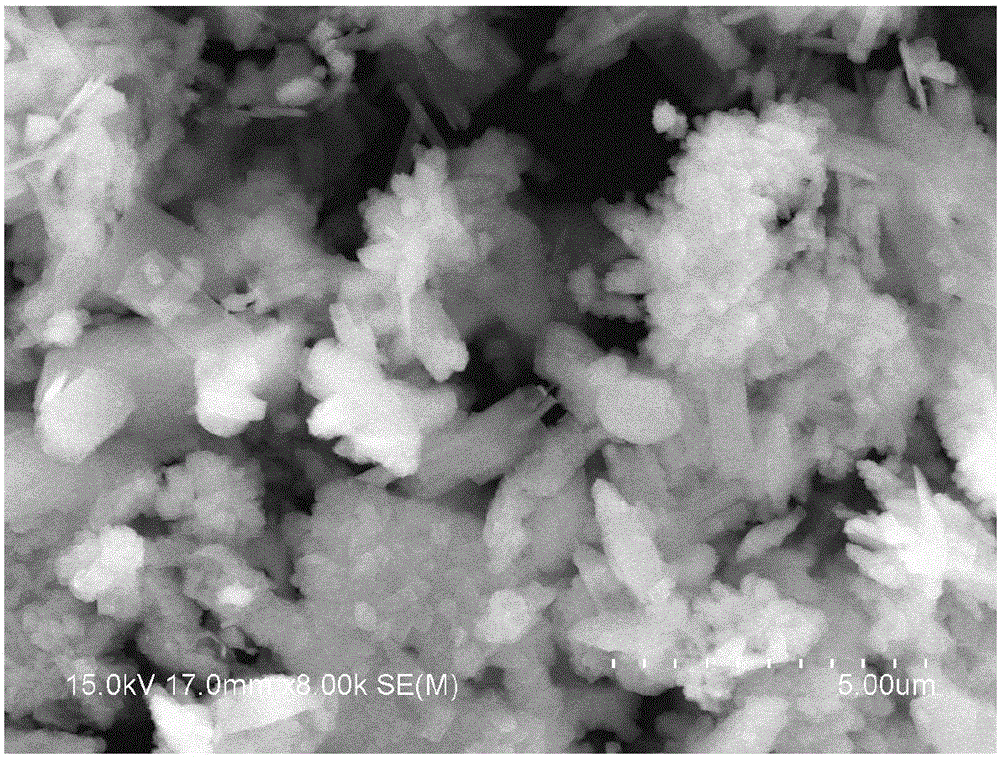

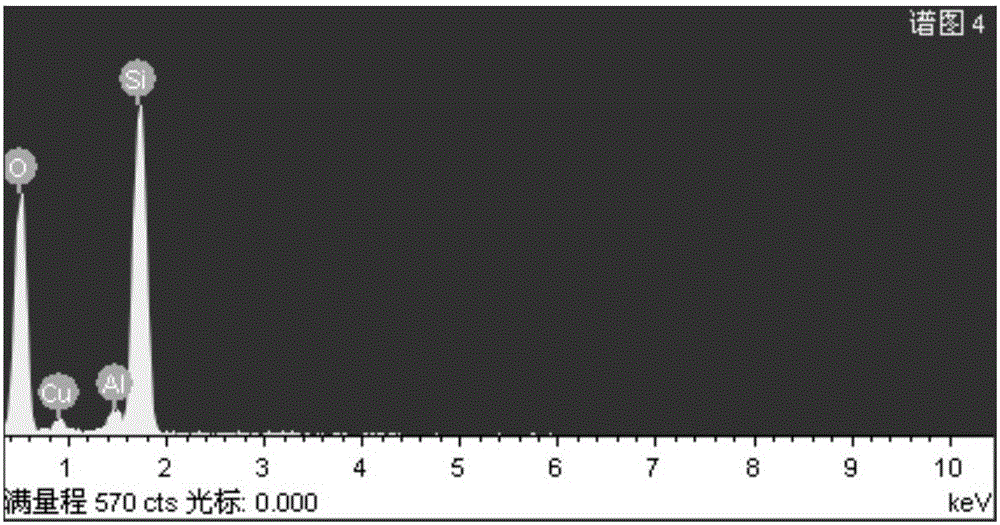

[0035] ZSM-5, CuO / ZSM-5 catalyst scanning electron microscope SEM picture and energy spectrometer EDS picture are shown in the accompanying drawings of ...

Embodiment 2- Embodiment 9

[0041] The treatment method of a kind of phenol waste water is the same as embodiment 1, changes the concentration of phenol waste water, the addition amount of CuO / ZSM-5 catalyst, the addition amount of sodium persulfate, the amount of adding sodium hydroxide are different, specifically see Table 1, other operations Same as Example 1, see Table 1 for phenol conversion rate and COD removal rate after treatment.

[0042] Table 1

[0043]

[0044] The preparation of the CuO / ZSM-5 catalyst used in embodiment 2-4 is specifically:

[0045] A kind of preparation of CuO / ZSM-5 catalyst comprises the following steps:

[0046] (1) Adopt commercial ZSM-5 zeolite (silicon-aluminum ratio (SiO 2 / Al 2 o 3 )=18~30; relative crystallinity: Na type>85%; pore size: ), take 150mL of deionized water to dissolve 1.624g of copper nitrate (concentration is 0.0577mol / L), impregnate 5g of dried ZSM-5 powder with this solution, and stir in a constant temperature water bath at 60°C for 5h to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com