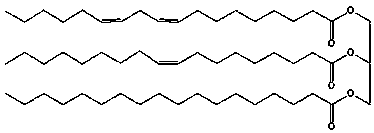

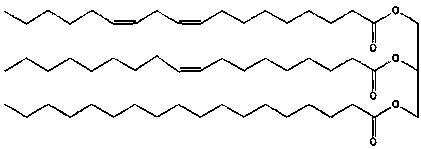

The preparation method of 1-stearic acid-2-oleic acid-3-linoleic acid glyceride

A technology of glyceryl linoleate and stearic acid, which is applied in the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., to avoid the use of a large amount of toxic organic solvents, good yield, and good extraction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Citrus seeds are washed with distilled water, dried, and pulverized. Put 100 g of citrus seed powder in a beaker, add 250 ml of water and 50 ml of ionic liquid 1-butyl-3-methylimidazole hexafluorophosphate, 25 Stir at ℃ for 3 hours, and filter with suction; the filtrate was extracted and washed with 100 ml of ethyl acetate for 3 times, combined with the ethyl acetate extraction and washing liquid, and the ethyl acetate was recovered by distillation under reduced pressure to obtain 41.0 g of the citrus seed oil mixture; the oil mixture was separated by chromatography column, The isolated pure glycerolipid 5.15 was obtained with a yield of 5.15%, and the isolated pure glycerolipid was characterized by nuclear magnetic resonance; the mixed solution of water and ionic liquid was distilled under reduced pressure to remove water, and the ionic liquid was recovered.

[0026] Using silica gel as a filler, the oil mixture is purified by column chromatography, charac...

Embodiment 2

[0031] Example 2: Put 20.0 g of citrus seed powder in a beaker, add 5.0 ml of water and 10.0 ml of ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate, stir at 25°C for 3 hours, and filter with suction; the filtrate Wash 3 times with 100ml of ethyl acetate, combine the ethyl acetate extract and washing solution, and recover ethyl acetate by distillation under reduced pressure to obtain 8.15g of citrus seed oil mixture; the oil mixture is separated by chromatographic column to obtain 0.862 g of isolated pure glyceride g, yield 4.31%.

Embodiment 3

[0032] Example 3: Put 20.0 g of citrus seed powder in a beaker, add 20.0 ml of water and 10.0 ml of ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate, stir at 25°C for 3 hours, and filter with suction; the filtrate Extract and wash with 100ml of ethyl acetate for 3 times, combine the extract and washing solution of ethyl acetate, and recover ethyl acetate by distillation under reduced pressure to obtain 8.27g of citrus seed oil mixture; the oil mixture is separated by chromatographic column to obtain 0.912 g of isolated pure glyceride g, yield 4.56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com