Production method for biomass diesel oil and bunker fuel oil

A technology for biomass diesel and production method, which is applied in chemical instruments and methods, hydrocarbon oil treatment products, treatment of hydrocarbon oil, etc., can solve the problems of high asphaltene and metal content, restricting the operation cycle of hydrogenation units, etc., and achieves reaction pressure. Low, long operating cycle of the device, reducing the effect of operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of catalyst:

[0050] Take 141.0 g of macroporous dry rubber powder, add 3.0 g of scallop powder, 2.5 g of borax (analytical pure), and mix well. Dissolve 8.0g of commercially available PVA1788 powder in 115mL of water under stirring and heating slowly. After the dissolution is complete, add it to the well-mixed dry rubber powder. , the extruded strips were dried at 120°C for 5 hours, and then baked at 550°C for 3 hours, then taken out and recorded as carrier a. The pore structure properties of the carrier are shown in Table 1. Take 4.01g of molybdenum oxide (AR), 1.40g of basic nickel carbonate (AR), 0.81g of concentrated phosphoric acid (AR), add 100mL of water, continue to heat and reflux under stirring, stop heating after the solution becomes transparent, and cool down to room temperature for later use. Take 80g of carrier sample a and impregnate it by pore saturation method. After impregnation, let it air in a fume hood for 3 hours, then dry it at 120°...

Embodiment 2

[0080] Preparation of catalyst:

[0081] Take 141.0 g of macroporous dry rubber powder, add 3.0 g of scallop powder, 2.5 g of borax (analytical pure), and mix well. Dissolve 8.0g of commercially available PVA1788 powder in 115mL of water under stirring and heating slowly. After the dissolution is complete, add it to the well-mixed dry rubber powder. , the extruded bar was dried at 150°C for 6 hours, and then baked at 600°C for 5 hours and then taken out, which was designated as carrier b. Take 4.01g of molybdenum oxide (AR), 1.40g of basic nickel carbonate (AR), 0.81g of concentrated phosphoric acid (AR), add 100mL of water, continue to heat and reflux under stirring, stop heating after the solution becomes transparent, and cool down to room temperature for later use. Take 80g of carrier sample b, impregnate by pore saturation method, dry in fume hood for 3 hours after impregnation, dry at 150°C for 3 hours, bake in muffle furnace at 450°C for 20 hours, record as catalyst II....

Embodiment 3

[0106] Hydrofining of biomass oil:

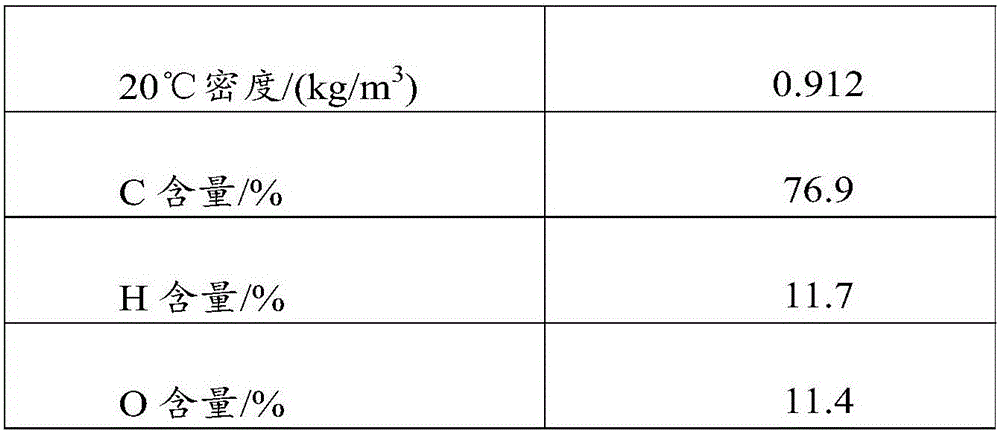

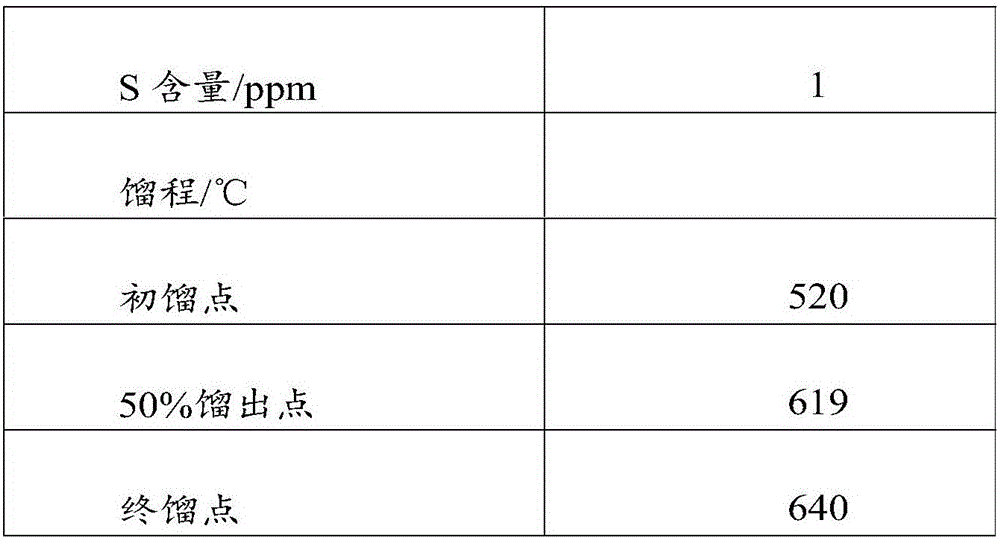

[0107] Biomass oil was firstly hydrogenated on the fixed bed hydrogenation test device, and the biomass oil was Xinjiang cottonseed oil, and its main properties are shown in Table 2. The hydrogenation catalyst adopts the commercial hydrogenation refining catalyst FHUDS5.

[0108] The hydrogenation operating conditions are: pressure 8.0MPa, reaction temperature 380°C, space velocity 5.0h -1 , The volume ratio of hydrogen to oil is 500.

[0109] Under the above operating conditions, Xinjiang cottonseed oil was subjected to hydrorefining to obtain hydrorefined cottonseed oil, the properties of which are shown in Table 11.

[0110] Table 11 Xinjiang cottonseed oil hydrorefined oil properties

[0111] Density at 20°C / (kg / m 3 )

0.812

C content / %

80.9

H content / %

14.6

O content / %

4.7

S content / ppm

<1

Fraction yield / %

<520℃

66.1

>520℃

33.9

[0112]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com