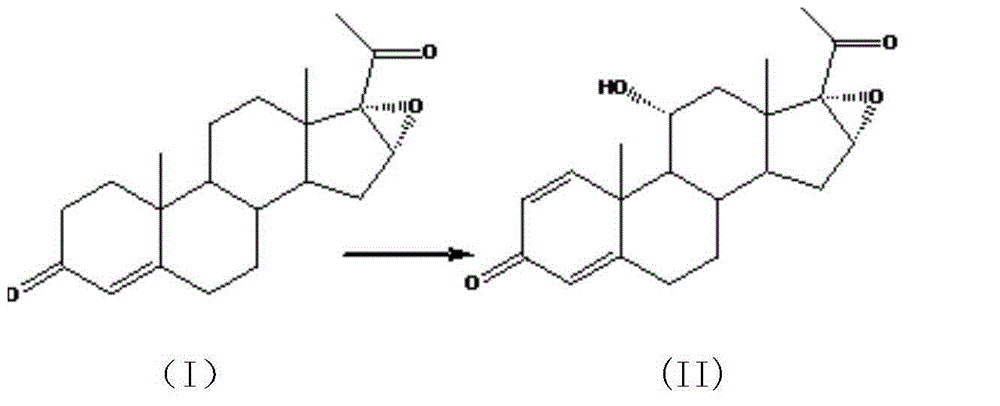

Method for preparing 16alpha, 17alpha-epoxy-11alpha-hydroxy-pregna-1,4-diene-3,20-dione through combined microbial fermentation

A combined fermentation and microorganism technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems that the yield and content of the target product do not exceed 50%, and are not easy to repeat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The selection of embodiment 1 fermentation medium

[0040] In the following examples, the influence of the fermentation medium on the conversion rate of the target product was investigated. Incline, seed cultivation method as described in the summary of the invention.

Embodiment 1-1

[0042] In 1L of water, ferment substrate 16α, 17α-epoxy progesterone 30g, fermentation medium components glucose 20g, sucrose 20g, silkworm chrysalis powder 5g, corn steep liquor 20g, diammonium phosphate 5g, ammonium dihydrogen phosphate 2g, soak Enemy 0.2g, pH 6.0. For the secondary culture of Arthrobacter simplex, after 24 hours of primary seed culture, insert 10% of the inoculum into the secondary seed medium, and after 22 hours of secondary culture, insert 15% of the inoculum into the above fermentation medium ; After 24 hours of culturing the primary seeds of Ochraus ochratum, they were inserted into the above-mentioned fermentation medium according to 30% inoculum amount. Use a 5-ton fermenter for conversion, with a liquid volume of 80%, a tank pressure of 0.05MPa, and an air flow of 40m 3 / hr, temperature 28°C, stirring 180rpm, conversion for 72 hours, sampling by TLC analysis, the conversion of the substrate was complete, the sample was extracted with ethyl acetate, ...

Embodiment 1-2

[0045] In 1L of water, ferment substrate 16α, 17α-epoxyprogesterone 30g, fermentation medium components glucose 30g, sucrose 20g, silkworm chrysalis powder 5g, corn steep liquor 20g, diammonium phosphate 5g, ammonium dihydrogen phosphate 2g, soak Enemy 0.2g, pH 6.0. For the secondary culture of Arthrobacter simplex, after 24 hours of primary seed culture, insert 10% of the inoculum into the secondary seed medium, and after 22 hours of secondary culture, insert 15% of the inoculum into the above fermentation medium ; After 24 hours of culturing the primary seeds of Ochraus ochratum, they were inserted into the above-mentioned fermentation medium according to 30% inoculum amount. Use a 5-ton fermenter for conversion, with a liquid volume of 80%, a tank pressure of 0.05MPa, and an air flow of 40m 3 / hr, temperature 28°C, stirring 180rpm, conversion for 72 hours, sampling by TLC analysis, the conversion of the substrate was complete, the sample was extracted with ethyl acetate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com