High-strength tooth-form composite halogen-free photovoltaic line cable

A compound halogen-free, high-strength technology, used in insulated cables, power cables with shielding/conducting layers, cables, etc., can solve the problems of easily damaged cable cores, toxic and harmful gases, troublesome installation, etc. It has the effect of winding with mixed wire, good limit and fixing effect, and increasing extrusion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

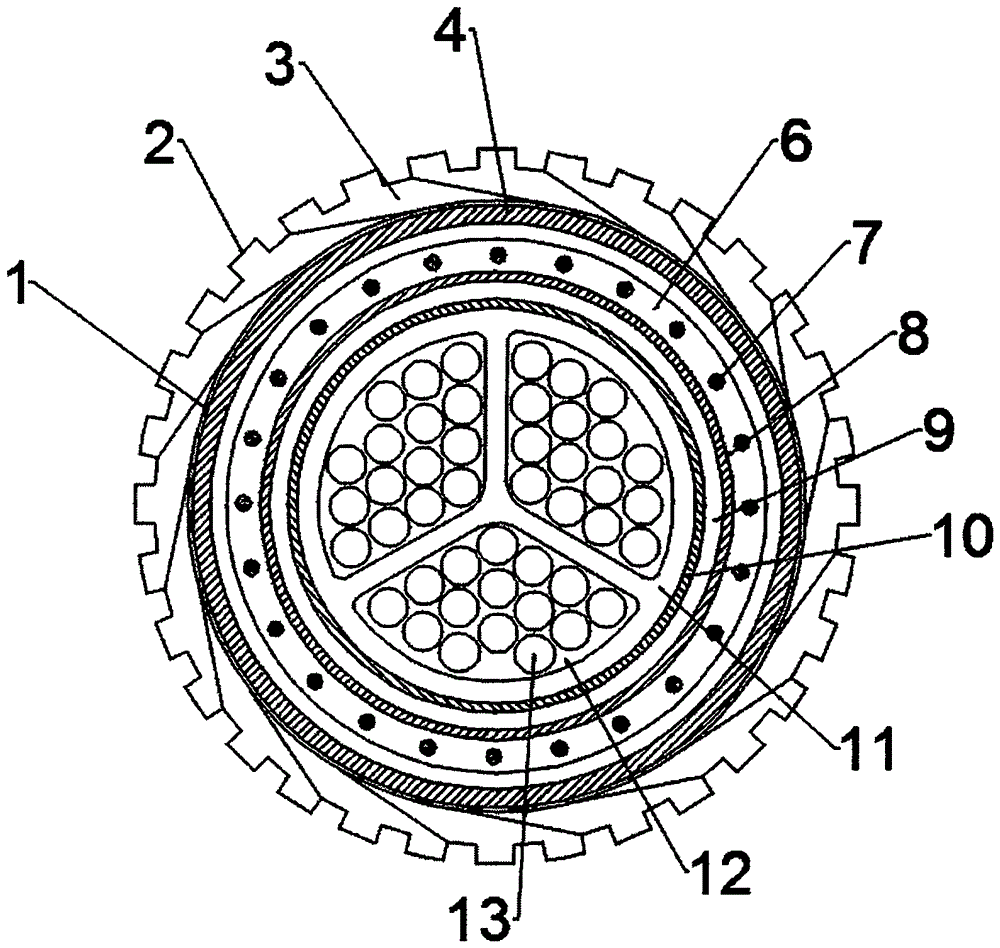

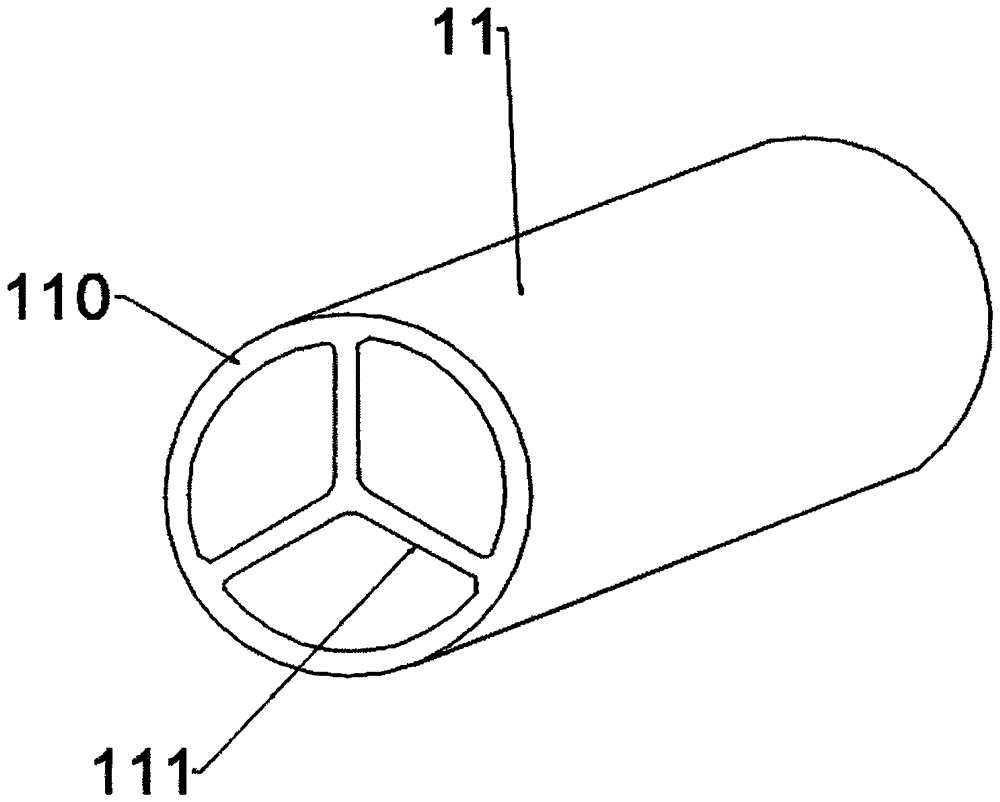

[0015] see Figure 1~2 , a high-strength tooth-shaped composite halogen-free photovoltaic line cable, including an elastic support frame 11, a conductor core wire 13, a fluoroplastic insulating layer 9, a buffer layer 6, a steel wire braided armor layer 4, an insulating silicone heat dissipation layer 1 and a heat dissipation belt 3. The conductor core wire 13 is made of copper material, and is made of an oxygen-free electrical round copper rod through a continuous annealing machine and a small drawing machine to make a round copper wire of Φ0.25-0.35mm, and the tinned round copper wire passes through the bundle The conductor core wires 13 twisted by wire machines, several conductor core wires 13 are twisted into three bundles and evenly arranged in the elastic support frame 11 on the circumference, and the space between the elastic support frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com