A process for preparing camellia petal-based sulfur and nitrogen co-doped wrinkled carbon nanosheets by explosion method and a preparation method for supercapacitor electrodes

A technology for supercapacitors and carbon nanosheets, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of high equipment requirements and low product yield, and achieve simple preparation methods, high specific surface area, and high ratio The effect of capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Washing, drying and pulverizing the collected biomass raw materials withered camellia petals, passing through a 60-mesh sieve, and taking the part under the sieve. Weigh 2g of the under-sieve part and 2g of ammonium persulfate and put them into an agate mortar for grinding at the same time to make them fully mixed, transfer the uniform mixture to a magnetic boat for compaction with a medicine spoon, put it into a tube furnace to heat up under the protection of nitrogen To the reaction target temperature, the reaction is carried out, and the temperature is kept at 800° C. for 2 hours to form sulfur and nitrogen co-doped wrinkled carbon nanosheets.

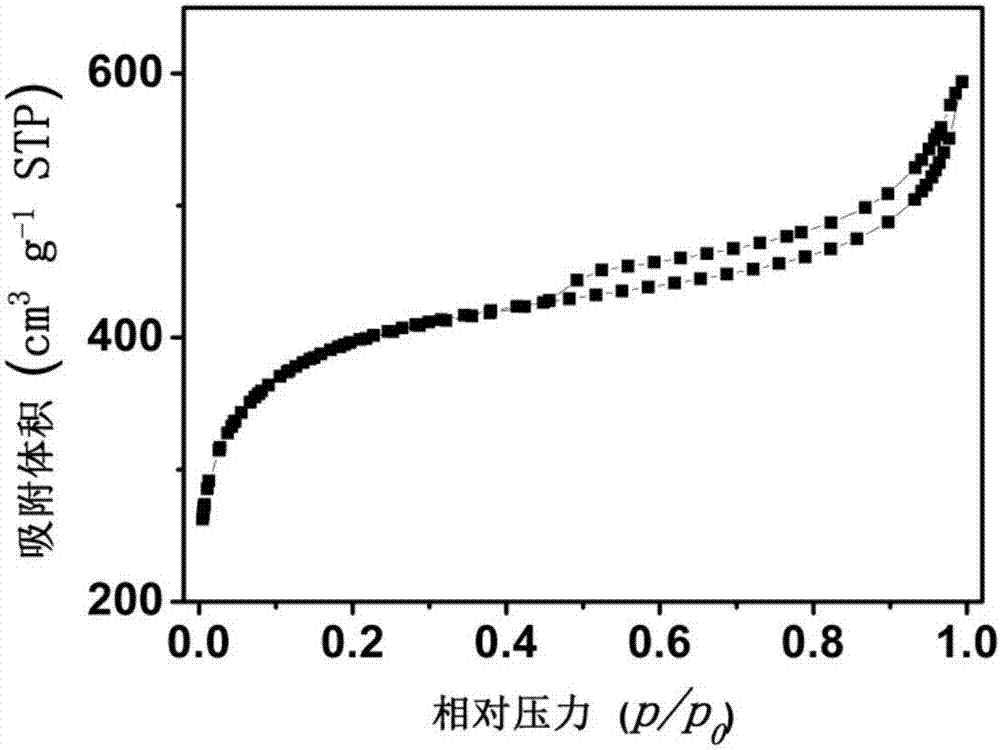

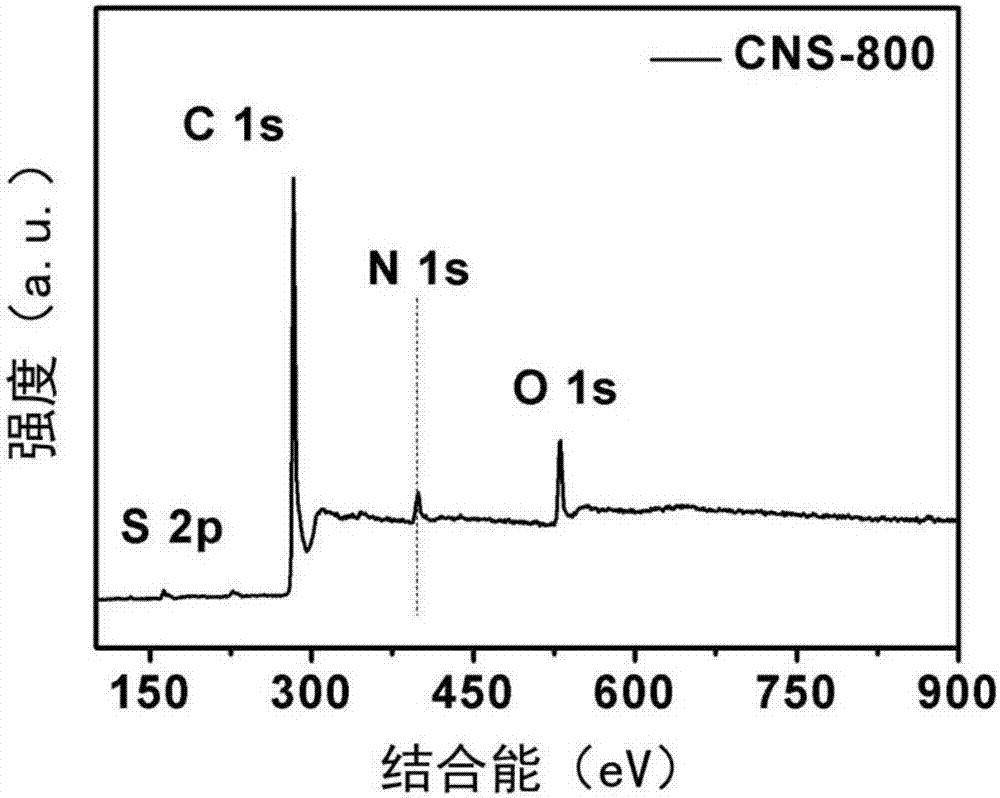

[0045] The obtained camellia petal-based sulfur and nitrogen co-doped wrinkled carbon nanosheets were washed and dried. After testing, its specific surface area reaches 1500m 2 g -1 , with a total pore volume of 0.91 cm 3 g -1 , with a sulfur content of 2% and a nitrogen content of 5%;

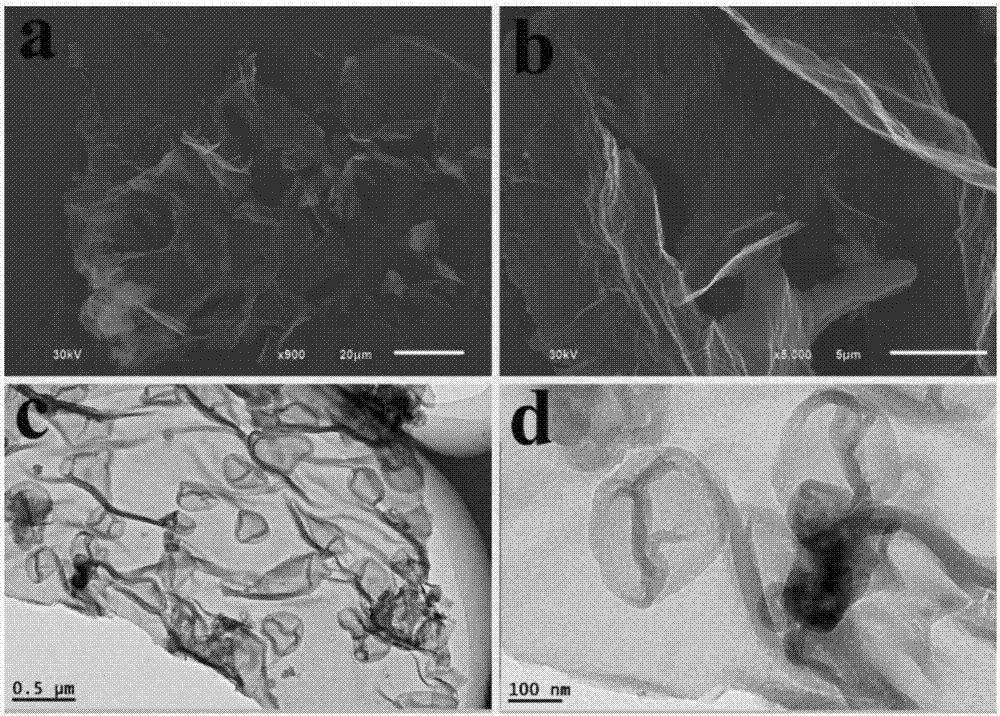

[0046] Depend on figure 1 In a a...

Embodiment 2

[0055] Washing, drying and pulverizing the collected biomass raw materials withered camellia petals, passing through a 60-mesh sieve, and taking the part under the sieve. Weigh 2g of the under-sieve part and 2g of ammonium persulfate and put them into an agate mortar for grinding at the same time to make them fully mixed, transfer the uniform mixture to a magnetic boat for compaction with a medicine spoon, put it into a tube furnace to heat up under the protection of nitrogen The reaction is carried out until the reaction target temperature is maintained at 700° C. for 2 hours to form sulfur and nitrogen co-doped wrinkled carbon nanosheets.

[0056] The obtained camellia petal-based sulfur and nitrogen co-doped wrinkled carbon nanosheets were washed and dried. After testing, its specific surface area reaches 1122m 2 g -1 , with a total pore volume of 0.61 cm 3 g -1 .

[0057] Mix acetylene black, polytetrafluoroethylene, camellia petal-based sulfur, and nitrogen co-doped ...

Embodiment 3

[0060] Washing, drying and pulverizing the collected biomass raw materials withered camellia petals, passing through a 60-mesh sieve, and taking the part under the sieve. Weigh 2g of the under-sieve part and 2g of ammonium persulfate and put them into an agate mortar for grinding at the same time to make them fully mixed, transfer the uniform mixture to a magnetic boat for compaction with a medicine spoon, put it into a tube furnace to heat up under the protection of nitrogen To the target reaction temperature, the reaction is carried out, and the temperature is kept at 900° C. for 2 hours to form sulfur and nitrogen co-doped wrinkled carbon nanosheets.

[0061] The obtained camellia petal-based sulfur and nitrogen co-doped wrinkled carbon nanosheets were washed and dried. After testing, its specific surface area reaches 1563m 2 g -1 , with a total pore volume of 0.95 cm 3 g -1 , it should be noted that the product yield is very low under this condition, below 10%.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com