Preparation method for large-area homogeneous organic-inorganic perovskite thin film and product and application of large-area homogeneous organic-inorganic perovskite thin film

A large-area, inorganic calcium technology, applied in the field of solar cells, can solve the problems of poor uniformity of perovskite film coverage, limitation of perovskite film preparation, waste of raw materials, etc., and achieve the goal of overcoming poor coverage uniformity, saving raw materials, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

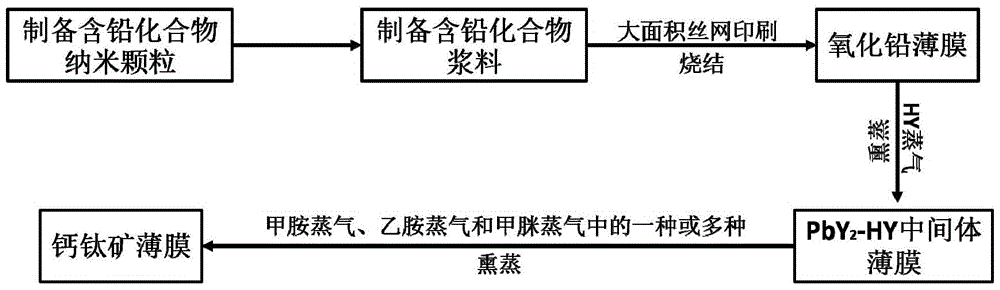

[0027] As mentioned above, the present invention provides a method for preparing a large-area homogeneous organic-inorganic perovskite film, such as figure 1 As shown, it comprises the following steps: 1) preparing lead-containing compound slurry; 2) setting a conductive substrate, and screen-printing the lead-containing compound slurry on it, and obtaining uniform lead oxide on the conductive substrate after sintering Thin film; 3) Put the lead oxide thin film obtained in step 2) into the first steam and the second steam and fumigate sequentially to prepare a large-area homogeneous organic-inorganic perovskite thin film.

[0028] What the method of the present invention prepares is a kind of large-area homogeneous organic-inorganic perovskite thin film, and described large area refers to that the area of described thin film is controllable in a large range, and this is caused by the characteristic of screen printing decided. Specifically, the screen printing technology det...

Embodiment 1

[0041] The present invention according to figure 1 The process shown prepares a large-area homogeneous organic-inorganic perovskite film, and the specific preparation steps are as follows:

[0042] 1) Preparation of PbO 2 Nanoparticles: PbO with a diameter of 5-100nm is synthesized by a solid-state chemical reaction method 2 nanoparticles.

[0043] 2)PbO 2 Preparation of conductive paste:

[0044] First weigh PbO with a diameter of 5-100nm in proportion 2 Nanoparticles and additives terpineol and ethyl cellulose, of which, PbO 2 The mass ratio of nanoparticles to additives is 1:4 to 1:15, and the PbO 2 Nanoparticles and additives were dissolved in an appropriate amount of absolute ethanol, then stirred for 30 minutes, ultrasonically crushed for 5 to 10 minutes, repeated 3 to 8 times, and then the dispersed PbO 2 The solution is ball milled for 5-20 hours, and finally the PbO is taken out 2 The dispersion was then rotary evaporated for 20 to 120 minutes to remove ethano...

Embodiment 2 and comparative example 1

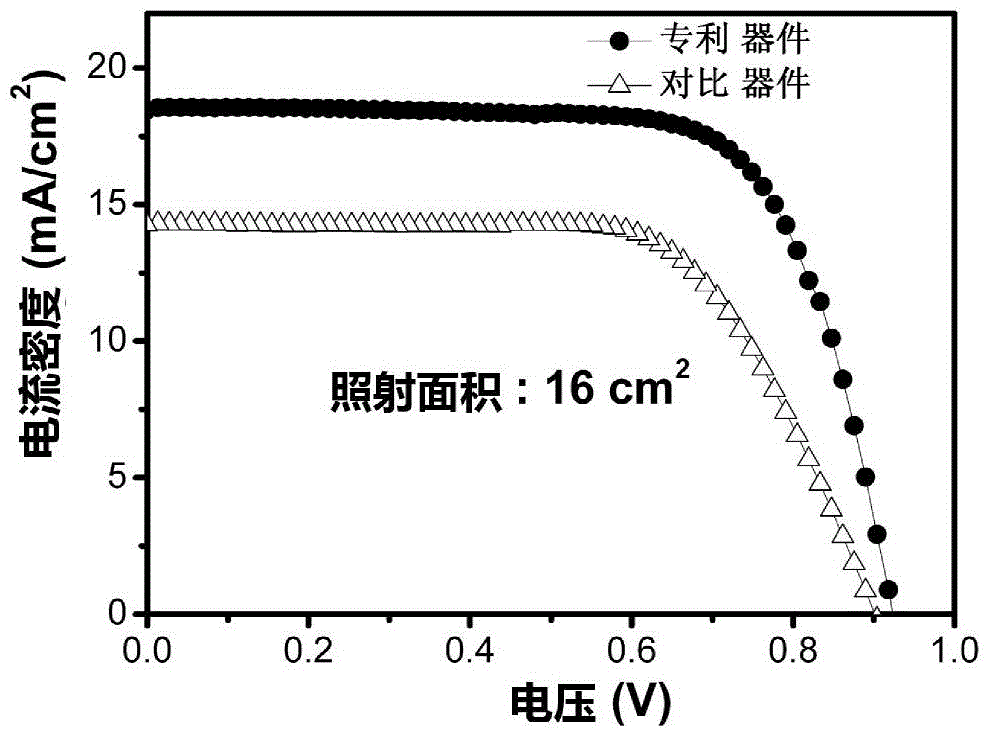

[0053] In order to show the advantages of preparing large-area homogeneous perovskite films more intuitively, a perovskite solar cell with p-i-n structure is provided below, from bottom to top are FTO transparent conductive glass, NiO dense layer, light harvesting layer (the perovskite film in embodiment 1 or the perovskite film in the prior art), Zn 2 SnO 4 Electron transport layer and metal electrode, specific implementation steps are:

[0054] Step S1) Substrate preparation: ultrasonically clean the FTO transparent conductive glass with deionized water, ethanol and acetone in sequence, and then treat it with ultraviolet and ozone for 15-30 minutes, and set aside;

[0055] Step S2) Preparation of the NiO dense layer: pre-preparing nickel acetylacetonate acetonitrile solution at a ratio of 1:10-100, preheating the clean FTO transparent conductive glass substrate at 400-600°C, and then pre-preparing the acetylacetonate Acetone-nickel-acetonitrile solution is sprayed on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com