Preparation device for selenium/carbon composite electrode material and control method

An electrode material and a technology for preparing a device, applied in the field of electrochemical power supply, can solve the problems of explosive mixed air, strong toxicity of hydrogen selenide, unsafety and the like, and achieve the effects of saving preparation cost, simple process and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

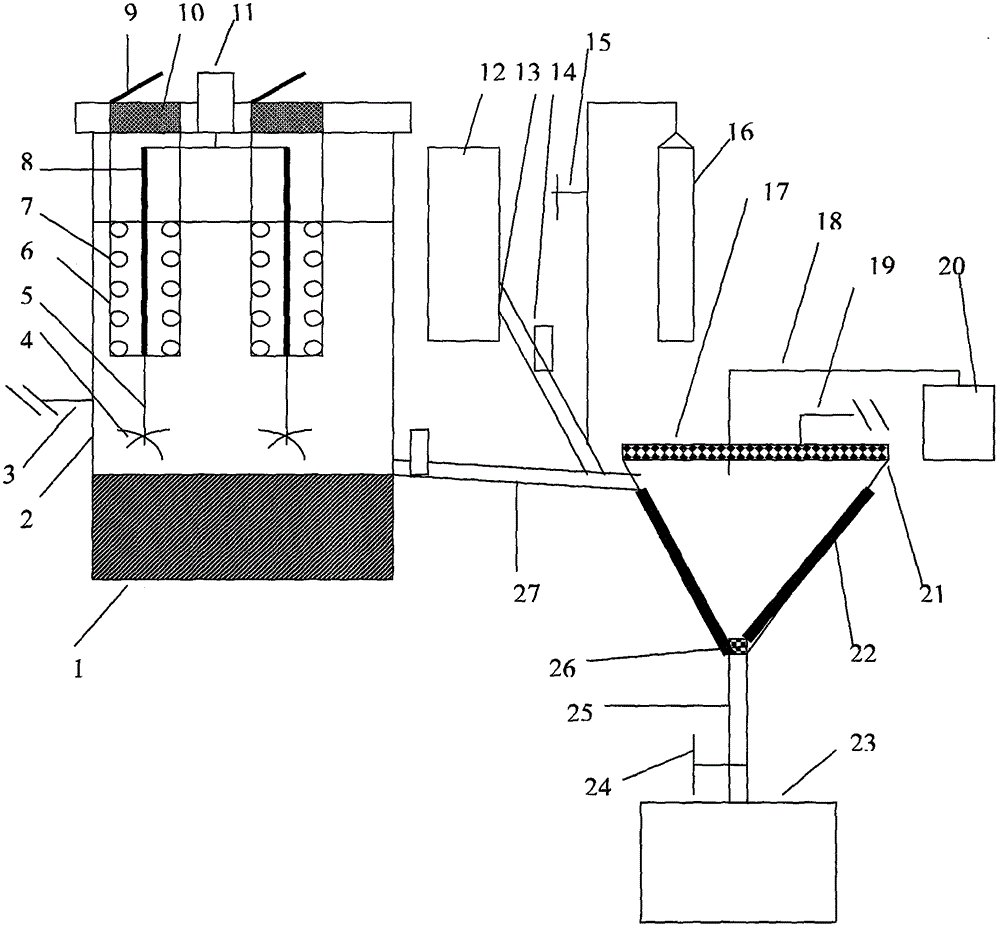

[0016] A preparation device for a selenium / carbon composite electrode material, including a stirring system, an injection system, a separation system and a waste collection system; it is characterized in that the stirring system includes 2 solid feeding pipes, a stirrer, a solid-liquid mixing tank and a heat collector type heater; the solid feeding pipe is provided with a cover and a feeding port, and 10 to 50 micropores with a diameter of 0.01 to 0.1 mm are arranged around the solid feeding pipe; the agitator is equipped with a power unit, a stirring rod, a blade, and a stirring rod There is a protective cover on the periphery; the power device of the agitator is set between two solid feeding pipes, the stirring rod passes through the solid feeding pipe, and then connects to the blade; the side wall of the solid-liquid mixing tank is provided with a liquid inlet pipe and a liquid outlet pipe. There is a collector heater at the bottom of the mixing tank; the liquid outlet pipe ...

Embodiment 2

[0025] Operation with embodiment 1, the mol ratio of sodium sulfite and selenium is 2.5; Sodium sulfite solution solubility is 12wt%; The mass ratio of selenium and carbon material is 4: 1; The mol ratio of ethanol and sodium sulfite is 1.3; Injection pressure 6MPa.

[0026] A selenium / carbon composite electrode material, comprising the following system:

[0027] Selenium simple substance, mass fraction 80%; carbon fiber, mass fraction 20wt%;

[0028] Selenium simple substance, mass fraction 80%; carbon / carbon composite material, mass fraction 20wt%;

[0029] Simple selenium, mass fraction 80%; hollow carbon spheres, mass fraction 20wt%;

[0030] Elemental selenium, mass fraction 80%; ordered mesoporous carbon, mass fraction 20wt%;

[0031] The selenium / carbon composite electrode material prepared in this example has fine particles and uniform distribution of selenium / carbon, which is used for the positive electrode of a lithium battery and has good electrochemical performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com