A method for preparing porous material with silkworm silk fibroin and carboxymethyl chitosan

A technology of carboxymethyl chitosan and porous materials, applied in medical science, prosthesis, etc., can solve problems such as poor water absorption, unsatisfactory uniformity of pore size, rough shape and surface, etc., and achieve soft texture and strong plasticity , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

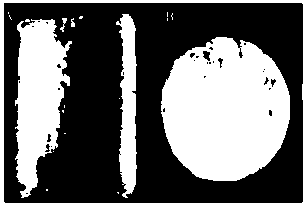

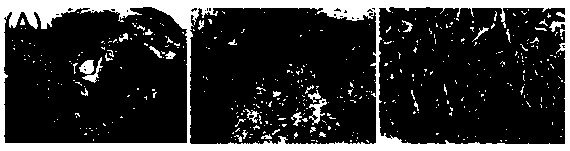

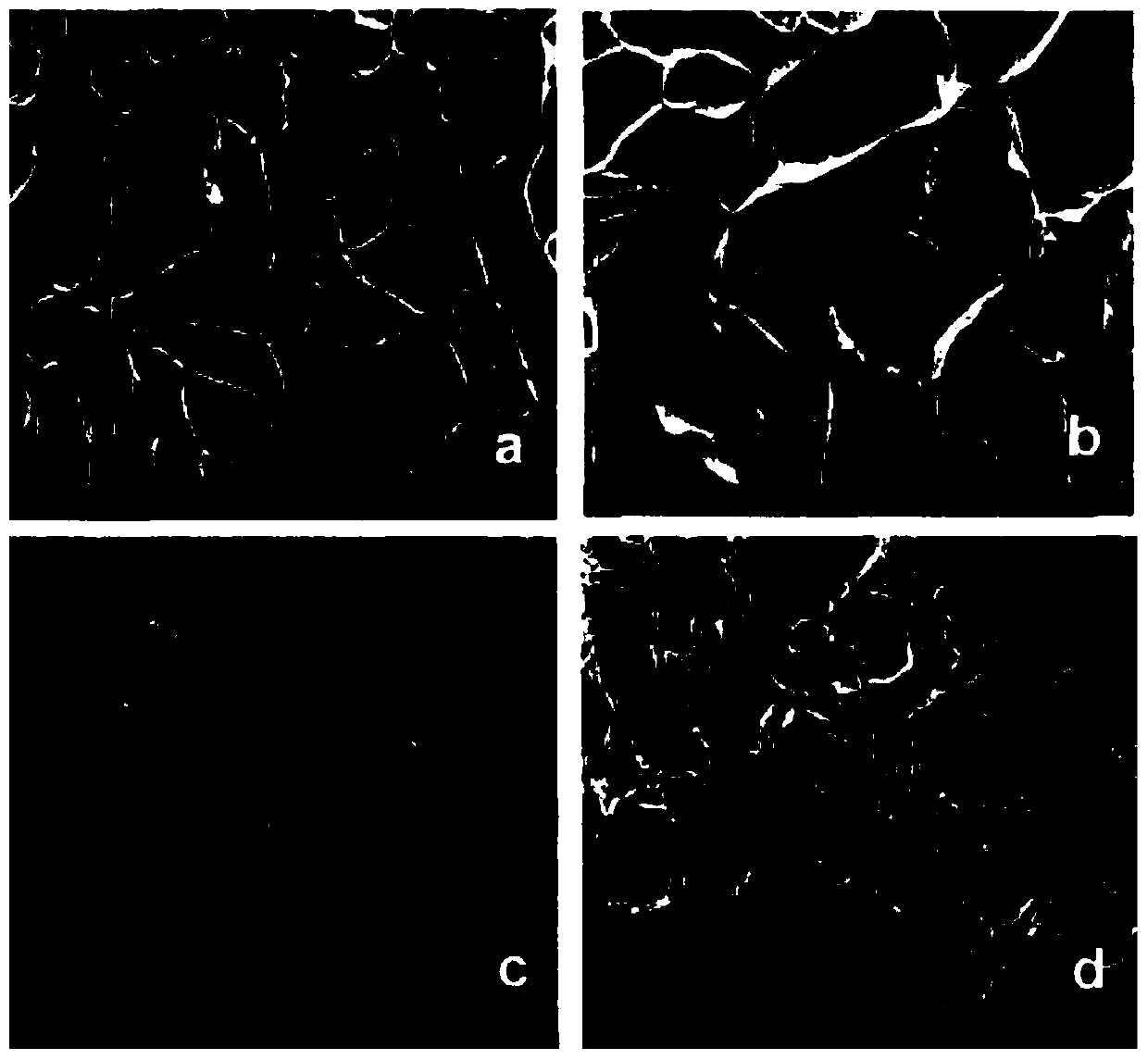

Image

Examples

Embodiment 1

[0035] A method for preparing a porous biological material, carried out according to the following steps:

[0036] Table 1 The ratio of silk fibroin / carboxymethyl chitosan and the ratio of glycerol and glutaraldehyde

[0037]

[0038] 1. Preparation of regenerated silk fibroin solution

[0039] at 0.5% Na 2 CO 3 Degumming in solution to obtain fibrous silk fibroin, and then in CaCl 2 、CH 3 CH 2 OH, H 2 O dissolved silk fibroin in a ternary solvent with a molar mass ratio of 1:2:8, and obtained a regenerated silk fibroin solution after dialysis. Specific steps are as follows:

[0040] (1) Degumming

[0041] Weigh a certain amount of silkworm cocoons, cut the cocoon shells into 1 square centimeter pieces after removing the silkworm chrysalis, add boiling 0.5% Na 2 CO 3 The solution (bath ratio is 1:50) was boiled for 30 minutes. Take out the cocoons and wash them repeatedly with deionized water until there is no greasy feeling. Repeat 2 times, and then detect with...

Embodiment 2

[0088] A method for preparing a porous biological material, carried out according to the following steps:

[0089] Table 2 silk fibroin / carboxymethyl chitosan ratio and the ratio of glycerol and glutaraldehyde

[0090]

[0091] 1. Preparation of regenerated silk fibroin solution

[0092] at 0.5% Na 2 CO 3 Degumming in solution to obtain fibrous silk fibroin, and then in CaCl 2 、CH 3 CH 2 OH, H 2 O dissolved silk fibroin in a ternary solvent with a molar mass ratio of 1:2:8, and obtained a regenerated silk fibroin solution after dialysis. Specific steps are as follows:

[0093] (1) Degumming

[0094] Weigh a certain amount of silkworm cocoons, cut the cocoon shells into 1 square centimeter pieces after removing the silkworm chrysalis, add boiling 0.5% Na 2 CO3 The solution (bath ratio is 1:50) was boiled for 30 minutes. Take out the cocoons and wash them repeatedly with deionized water until there is no greasy feeling. Repeat 2 times, and then detect with bitter y...

Embodiment 3

[0107] A method for preparing a porous biological material, carried out according to the following steps:

[0108] Table 3 silk fibroin / carboxymethyl chitosan ratio and the ratio of glycerol and glutaraldehyde

[0109]

[0110] 1. Preparation of regenerated silk fibroin solution

[0111] at 0.5% Na 2 CO 3 Degumming in solution to obtain fibrous silk fibroin, and then in CaCl 2 、CH 3 CH 2 OH, H 2 O dissolved silk fibroin in a ternary solvent with a molar mass ratio of 1:2:8, and obtained a regenerated silk fibroin solution after dialysis. Specific steps are as follows:

[0112] (1) Degumming

[0113] Weigh a certain amount of silkworm cocoons, cut the cocoon shells into 1 square centimeter pieces after removing the silkworm chrysalis, add boiling 0.5% Na 2 CO 3 The solution (bath ratio is 1:50) was boiled for 30 minutes. Take out the cocoons and wash them repeatedly with deionized water until there is no greasy feeling. Repeat 2 times, and then detect with bitter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com