Preparation method of regular octahedral bismuth fluoride material

A technology of regular octahedron and bismuth fluoride, which is applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve problems such as inability to obtain fluorination, energy consumption, environmental pollution, and expensive products, so as to avoid energy waste and protect The effect of simplifying the environment and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 0.485gBi(NO 3 ) 3 ·5H 2 O was dissolved in 19ml of deionized water, and 1ml of HNO was added 3 , configured as a bismuth nitrate solution with a concentration of 50mM; dissolve 0.42gNaF in 80ml of deionized water, add 2gPVP, and configure a sodium fluoride solution with a concentration of 0.125M; add the bismuth nitrate solution to the sodium fluoride solution, and stir After uniformity, let stand for reaction for 5 days; wash the obtained precipitates with deionized water and absolute ethanol three times respectively, and dry in a blast drying oven at 60° C. for 12 hours to obtain octahedral bismuth fluoride materials.

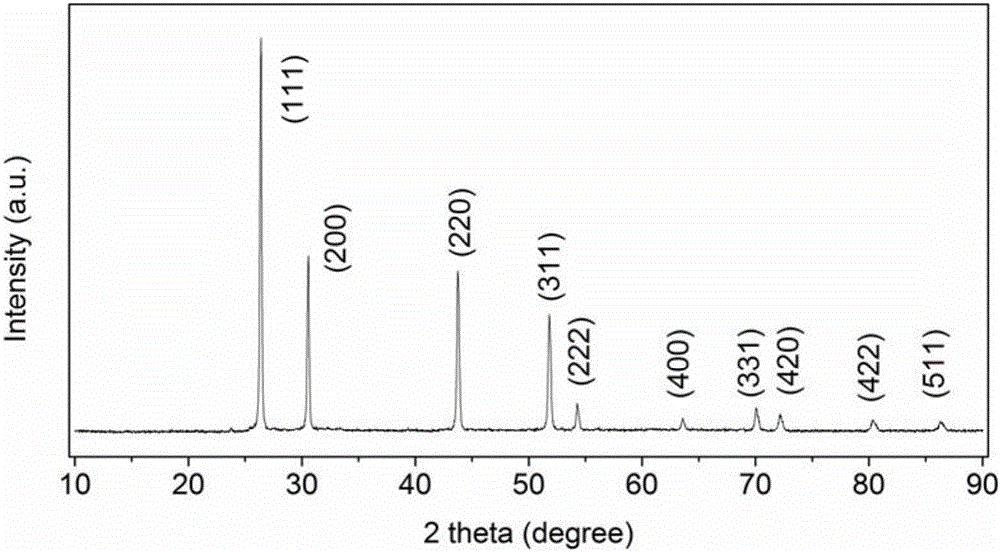

[0041] Carry out X-ray diffraction analysis to regular octahedral bismuth fluoride material, the result is as follows figure 1 As shown, the prepared bismuth fluoride has a single composition, belongs to the face-centered cubic crystal system (JCPDS51-0944), has a space group of Fm3m, and has high crystallinity.

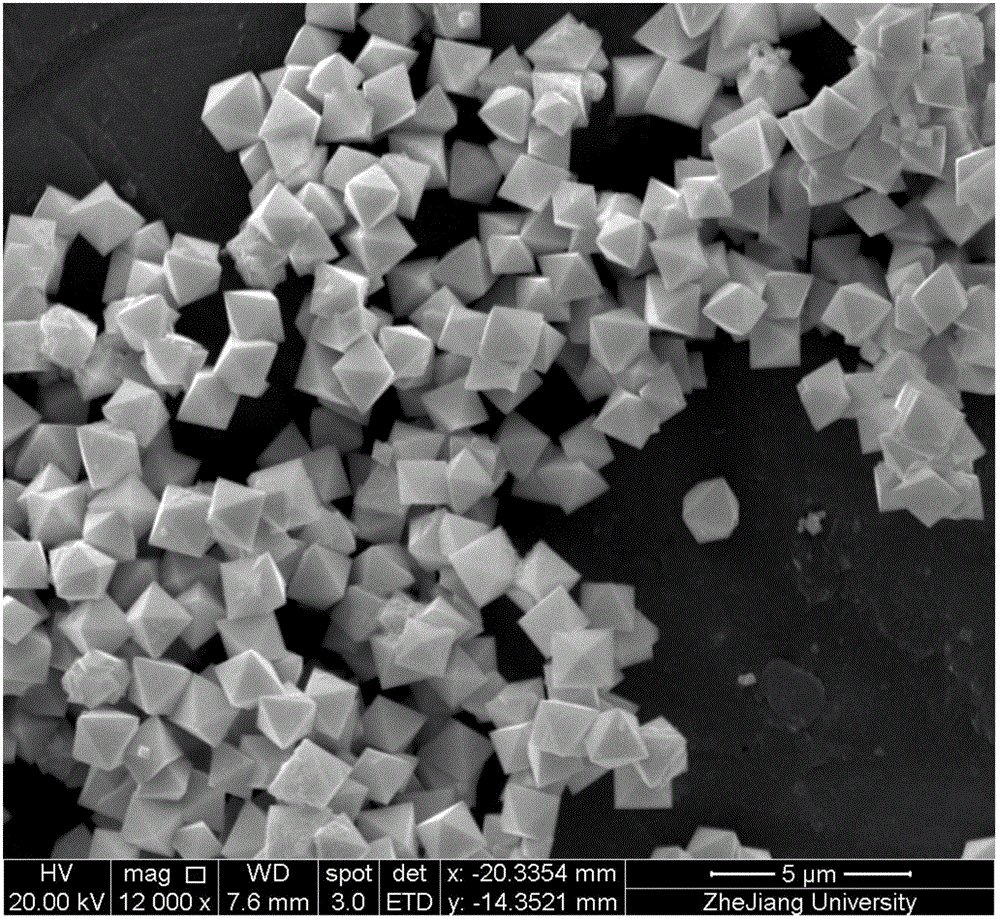

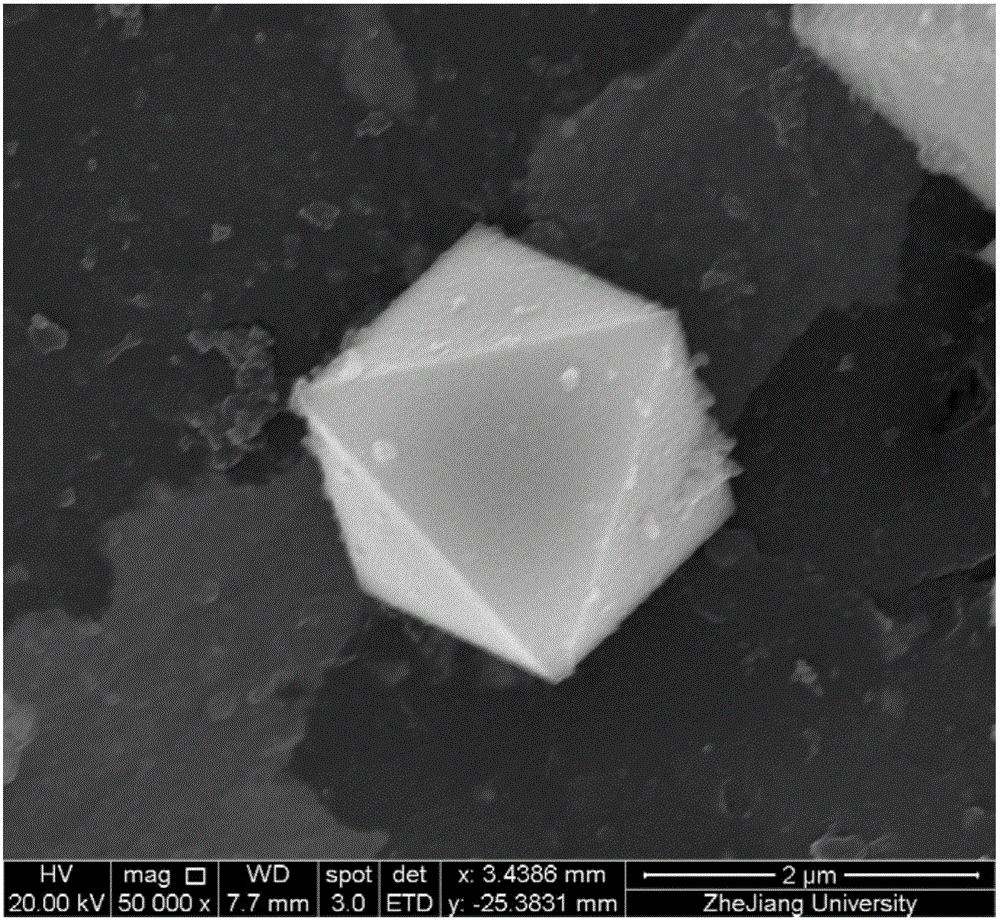

[0042] SEM analysis of octahedral ...

Embodiment 2

[0044] 0.485gBi(NO 3 ) 3 ·5H 2O was dissolved in 19ml of deionized water, and 1ml of HNO was added 3 , configured as a bismuth nitrate solution with a concentration of 50mmol / L; dissolve 0.42gNaF in 80ml of deionized water, add 0.5gPVP, and configure a NaF solution with a concentration of 0.125mol / L; add the bismuth nitrate solution to the sodium fluoride solution After mixing evenly, let it stand at 25°C for 5 days; wash the obtained precipitates with deionized water and absolute ethanol three times respectively, and dry them in a blast drying oven at 60°C for 12 hours to obtain octahedral fluorine bismuth material. Scanning electron microscope analysis was carried out to the obtained product, such as Figure 5 As shown, it consists of octahedral micro-nano structures, and the octahedral structure has a single, uniform and regular pattern.

Embodiment 3

[0046] 0.485gBi(NO 3 ) 3 ·5H 2 O was dissolved in 19ml of deionized water, and 1ml of HNO was added 3 , configured as a bismuth nitrate solution with a concentration of 50mmol / L; dissolve 0.42gNaF in 80ml of deionized water, add 3gPVP, and configure a NaF solution with a concentration of 0.125mol / L; add the bismuth nitrate solution to the sodium fluoride solution , stirred evenly and left to react at 25°C for 5 days; the obtained precipitates were washed three times with deionized water and absolute ethanol respectively, and dried in a blast drying oven at 60°C for 12 hours to obtain octahedral fluorinated bismuth material. Scanning electron microscope analysis was carried out to the obtained product, such as Image 6 As shown, it consists of octahedral micro-nano structures, and the octahedral structure has a single, uniform and regular pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com