Biomembrane process packing ball

A biofilm method and filler ball technology, applied in the field of filler balls and asymmetric impeller biofilm method filler balls, can solve the problems of difficult biofilm growth, low flow rate, waste of design space, etc., to achieve ideal treatment effects and reduce resistance. , the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

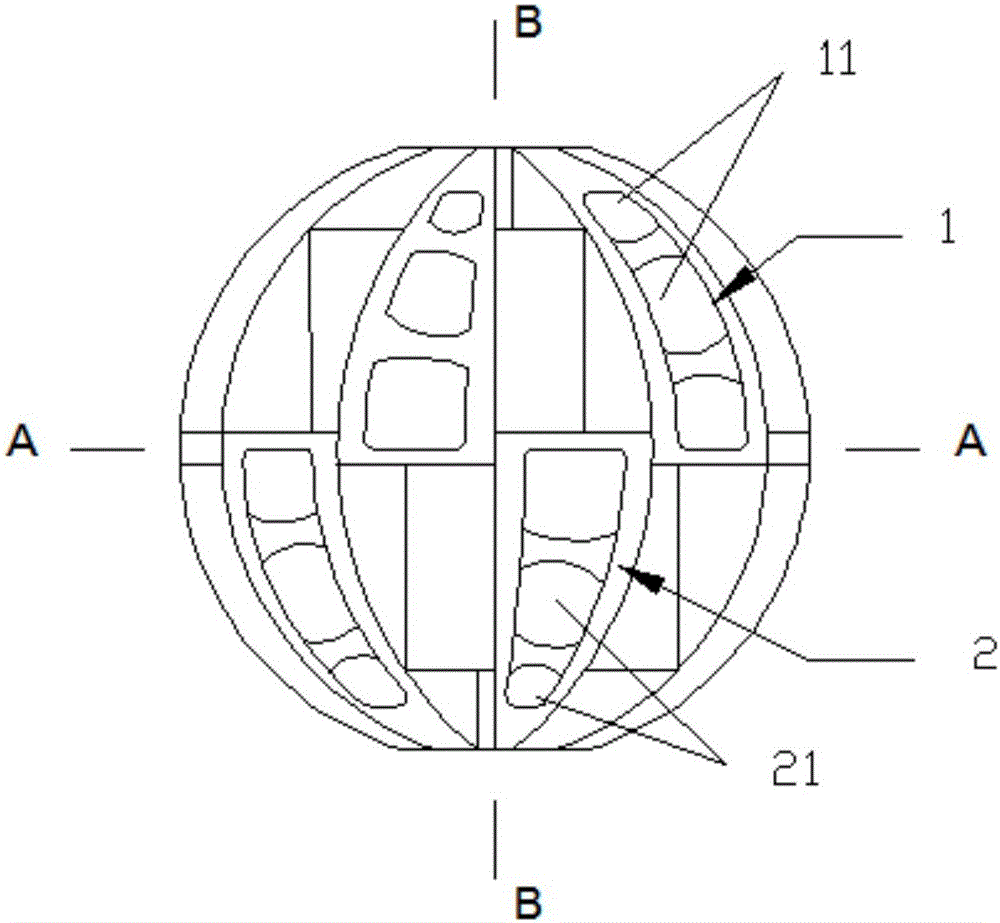

[0060] Such as Figure 1-3 As shown, this embodiment provides a biofilm packing ball, which has a non-symmetrical impeller structure, and any cross-section passing through the center of the ball, the two parts that divide the packing ball are not symmetrical with respect to the cross-section.

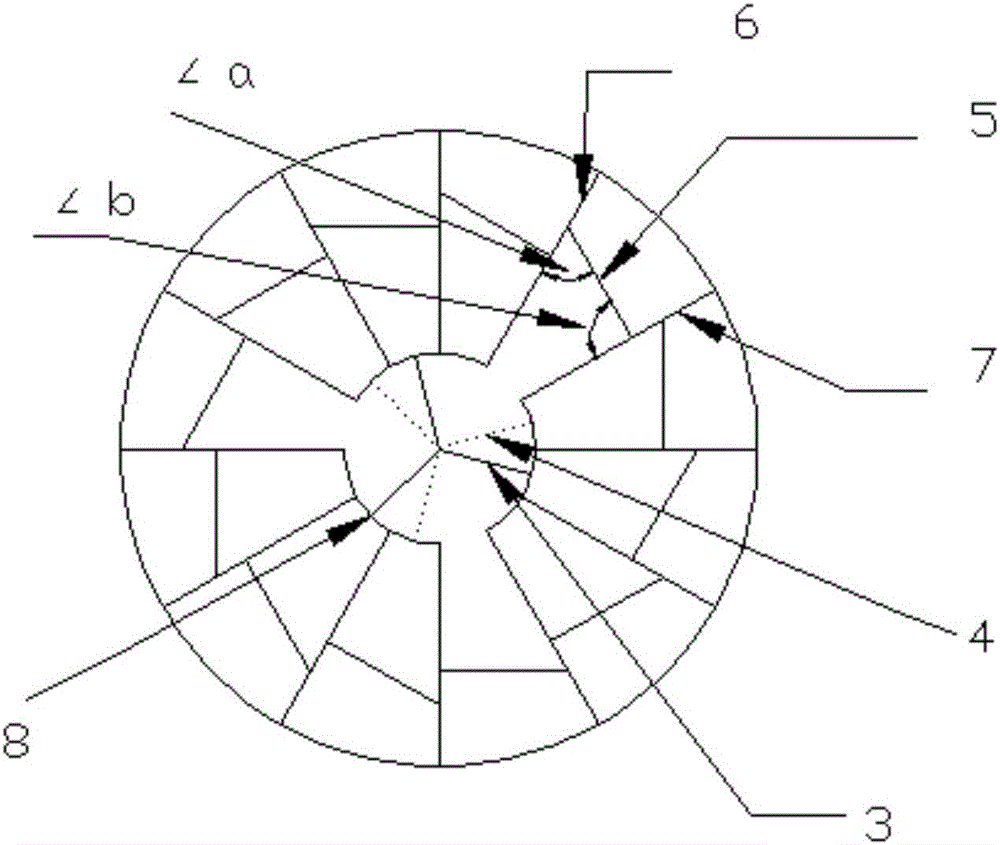

[0061] The filler ball is mainly composed of several blades, including spherical blades, axial blades, tangential blades and radial blades. The spherical blades include upper and lower hemispherical spherical blades, and the axial blades include upper and lower hemispherical axial blades;

[0062] Specifically, in this embodiment, the filler balls include:

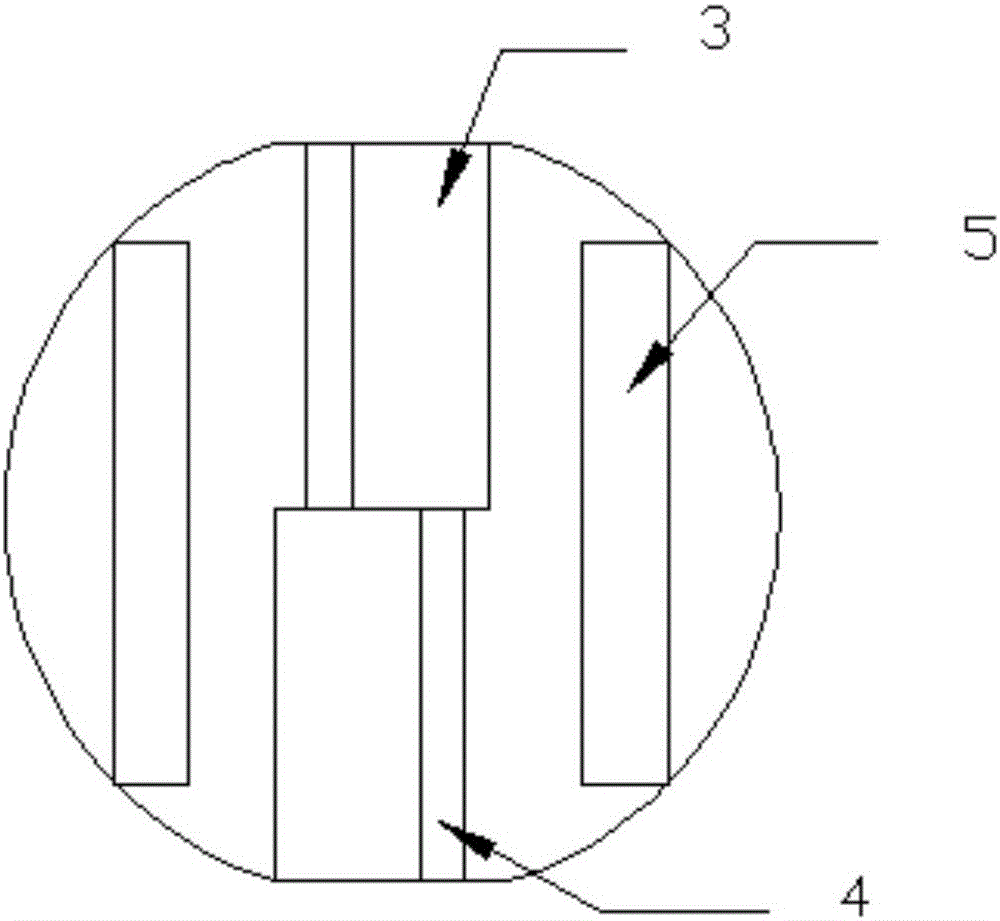

[0063] The upper hemisphere axial blade 3 and the corresponding lower hemisphere axial blade 4, the upper hemisphere axial blade 3 and the lower hemisphere axial blade 4 are staggered by 30° (such as figure 2 shown); the upper hemisphere axial blade 3 and the lower hemisphere axial blade 4 are trident impeller structures, and the ...

Embodiment 2

[0078] The difference between this embodiment and embodiment 1 is that

[0079] The radial blades of this embodiment are provided with elongated water holes, which can increase the water flow. The structural design of the strip-shaped water holes on the radial blades will reduce the overall specific surface area of the filler ball to a certain extent, so the size of the strip-shaped water holes should be as small as possible while ensuring smooth water flow.

Embodiment 3

[0081] The difference between this embodiment and embodiment 1 is that

[0082] In this embodiment, the height of the axial blades of the upper hemisphere is not equal to the height of the axial blades of the lower hemisphere, and the width is consistent, and the radius of the filler ball is 5cm;

[0083] The height of the axial blade of the upper hemisphere is 0.6 times the radius R of the filler ball, which is 3.0cm;

[0084] The height of the axial blade of the lower hemisphere is 1.2 times the radius R of the filler ball, which is 6.0cm;

[0085] The height of the tangential blade is 1.8 times the radius R, which is 9.0 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com