Permeable concrete and preparing method thereof

A permeable concrete and cement technology, which is applied in the field of road paving materials, can solve the problems of low strength of permeable concrete, inability to make permeable concrete pavement, vehicle driving, etc., and achieve good construction workability, large porosity, and good frost resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

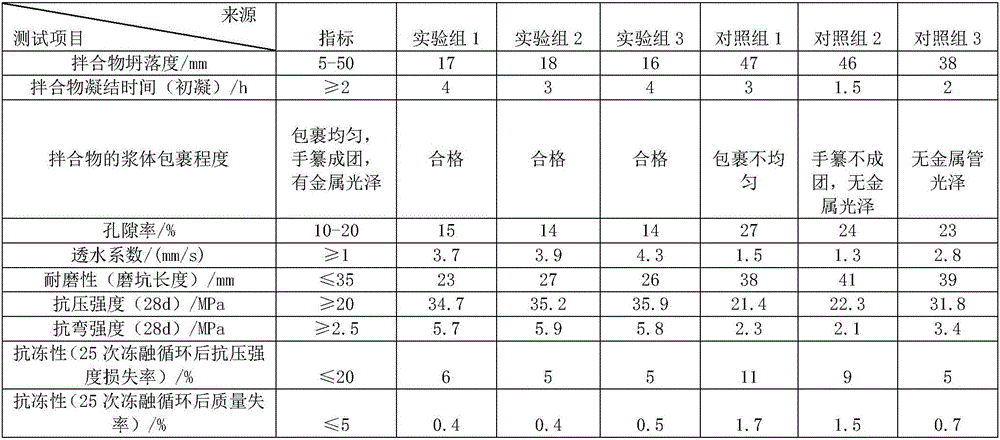

Examples

Embodiment 1

[0027] A permeable concrete, which consists of: 300kg of 425 ordinary Portland cement, 10kg of class II fly ash, 9.68kg of pozzolan, 18kg of carbide slag, 15kg of quartz sand with a particle size of 0.48mm, 2.2kg of triethanolamine, and 2.7kg of sodium sulfate kg, 2.5kg of aliphatic water reducer, 0.8kg of lignosulfonate retarder, 4.8kg of rosin soap foaming agent and 30kg of water.

[0028] The preparation method of described permeable concrete is:

[0029] A. Put 425 ordinary Portland cement, class II fly ash, pozzolan, carbide slag and quartz sand in a concrete mixer and mix for 5 minutes;

[0030] B. Add 21kg of water into the mixture obtained in step A and stir for 11min;

[0031] C. Add aliphatic water reducer, rosin soap foaming agent, lignosulfonate retarder, triethanolamine and sodium sulfate into the mixture obtained in step B and stir for 5 minutes;

[0032] D. Add the remaining 9 kg of water into the mixture obtained in step C and stir for 1 min, then vibrate and...

Embodiment 2

[0034] A permeable concrete, which consists of: 250kg of 325R ordinary Portland cement, 15kg of class II fly ash, 6.32kg of pozzolan, 25kg of carbide slag, 24kg of quartz sand with a particle size of 0.36mm, 5.3kg of triethanolamine, and 1.3kg of sodium sulfate kg, sulfamate water reducing agent 3.6kg, lignosulfonate retarder-1.7kg, rosin soap foaming agent 3.2kg and water 35kg.

[0035] The preparation method of described permeable concrete is:

[0036] A. Put 325R ordinary Portland cement, class II fly ash, pozzolan, carbide slag and quartz sand in a concrete mixer and mix for 3 minutes;

[0037] B. Add 24.5 g of water to the mixture obtained in step A and stir for 13 min;

[0038] C. Add sulfamate water reducer, rosin soap foaming agent, lignosulfonate retarder, triethanolamine and sodium sulfate to the mixture obtained in step B and stir for 2 minutes;

[0039] D. Add the remaining 10.5 kg of water into the mixture obtained in step C and stir for 3 minutes, then vibrate ...

Embodiment 3

[0041] A permeable concrete, which consists of: 277kg of 525 ordinary Portland cement, 12.6kg of class II fly ash, 7.84kg of pozzolan, 21.3kg of carbide slag, 20.4kg of quartz sand with a particle size of 0.42mm, 3.7kg of triethanolamine, Sodium sulfate 2.05kg, aliphatic water reducer 2.96kg, lignosulfonate retarder 1.2kg, rosin soap foaming agent 4.0kg and water 32.6kg.

[0042] The preparation method of described permeable concrete is:

[0043] A. Put 525 ordinary Portland cement, class II fly ash, pozzolan, carbide slag and quartz sand in a concrete mixer and mix for 4 minutes;

[0044] B. Add 22.8 g of water to the mixture obtained in step A and stir for 12 min;

[0045] C. Add aliphatic water reducer, rosin soap foaming agent, lignosulfonate retarder, triethanolamine and sodium sulfate into the mixture obtained in step B and stir for 3 minutes;

[0046] D. Add the remaining 9.78 kg of water into the mixture obtained in step C and stir for 2 minutes, then vibrate and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com