Chiral porous organic polymer material and preparation method

A kind of polymer material and organic technology, applied in the field of preparation of chiral porous organic polymer materials, can solve the problems of not easy to modify chiral centers, low specific surface area, etc., achieve wide industrial application prospects, simple preparation method, low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

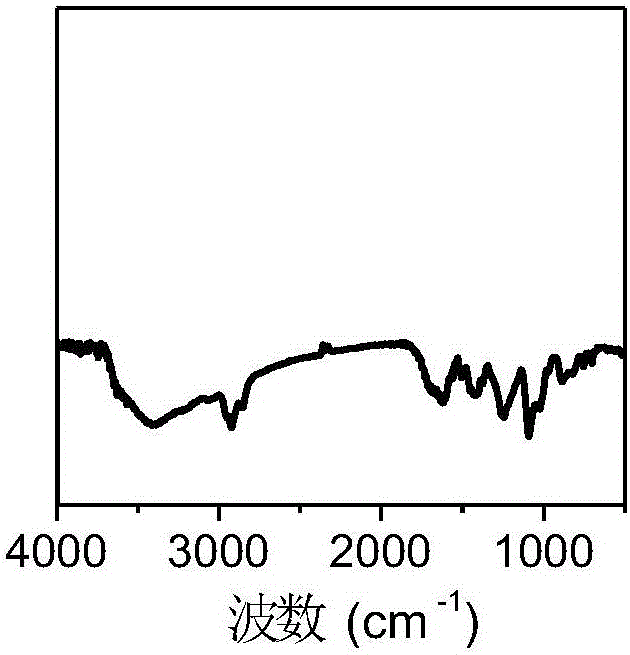

[0030] Under the protection of nitrogen, add 50 mg (0.10 mmol) of 3,3'-diphenyl-2,2'-binaphthol phosphoric acid, 35.5 μL (0.40 mmol) of dimethyl formal, and anhydrous 1,2 - Dichloroethane 2mL, stir to disperse evenly, then heat up to 50°C, add 64.9mg (0.40mmol) of anhydrous ferric chloride to the reaction bottle, and react at 50°C for 48 hours; after the reaction, filter the solid-liquid mixture , the obtained brown or black solid was washed three times with tetrahydrofuran, and then washed three times with 10-30 mL of methanol, water, dichloromethane, and acetone respectively; the obtained solid was extracted by Soxhlet with acetone for 4 hours, and finally depressurized After drying, a brown chiral porous organic polymer material was obtained. Its Fourier transform infrared spectrum (IR) is as follows figure 1 Shown, nitrogen adsorption-desorption isotherm (77K) as Figure 7 shown.

Embodiment 2

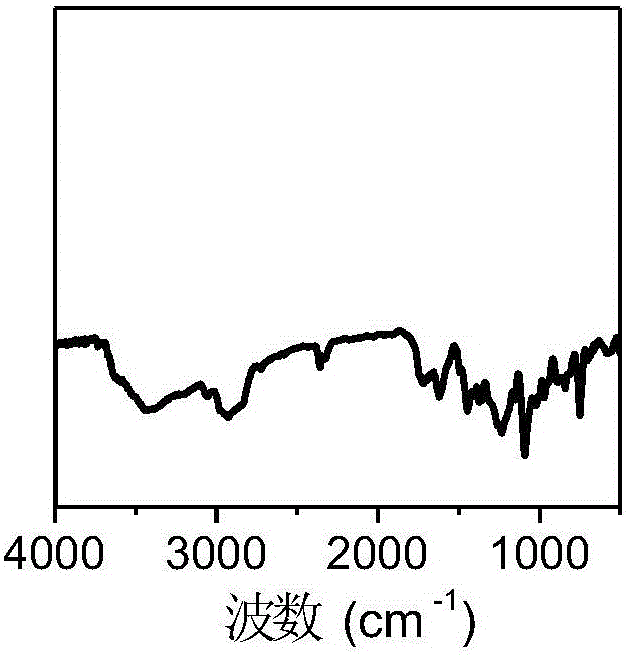

[0032] Under nitrogen protection, 50 mg (0.09 mmol) of 3,3'-bis-(4-methoxy)-phenyl-2,2'-binaphthol phosphoric acid, 32 μL (0.36 mmol), 2 mL of anhydrous 1,2-dichloroethane, stirred to disperse evenly, then heated up to 50°C, added 58mg (0.36mmol) of anhydrous ferric chloride to the reaction bottle, and reacted at 50°C for 48 hours; After the end, filter the solid-liquid mixture to obtain a brown or black solid, wash the solid three times with tetrahydrofuran, and then wash three times with 10-30 mL of methanol, water, dichloromethane, and acetone respectively; Extract for 4 hours, and finally dry under reduced pressure to obtain a brown chiral porous organic polymer material.

Embodiment 3

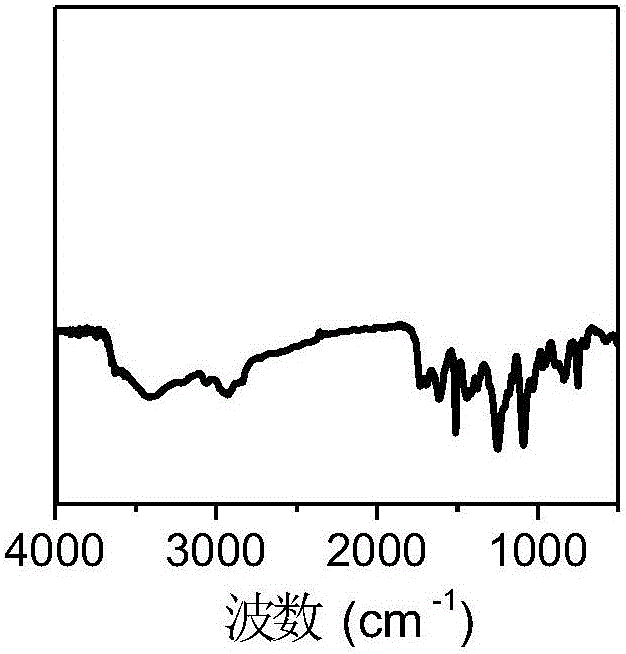

[0034] Under the protection of nitrogen, add 50 mg (0.083 mmol) of 3,3'-di-2-naphthyl-2,2'-binaphthol phosphoric acid, 29.5 μL (0.33 mmol) of dimethyl formal, and anhydrous 2mL of 1,2-dichloroethane, stir to disperse evenly, then heat up to 50°C, add 54.1mg (0.33mmol) of anhydrous ferric chloride to the reaction bottle, and react at 50°C for 48 hours; after the reaction, filter Solid-liquid mixture, the obtained brown or black solid was washed three times with tetrahydrofuran, and then washed three times with 10-30 mL of methanol, water, dichloromethane and acetone respectively; the obtained solid was extracted with acetone for 4 hours, Finally, it was dried under reduced pressure to obtain a brown chiral porous organic polymer material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com