Preparation method of nano-structure polyaniline

A nanostructure, polyaniline technology, used in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as being unsuitable for large-scale production, difficult to obtain a large number of products, and difficult to achieve regulation, etc. Simple operation, simplified synthesis process, strong controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

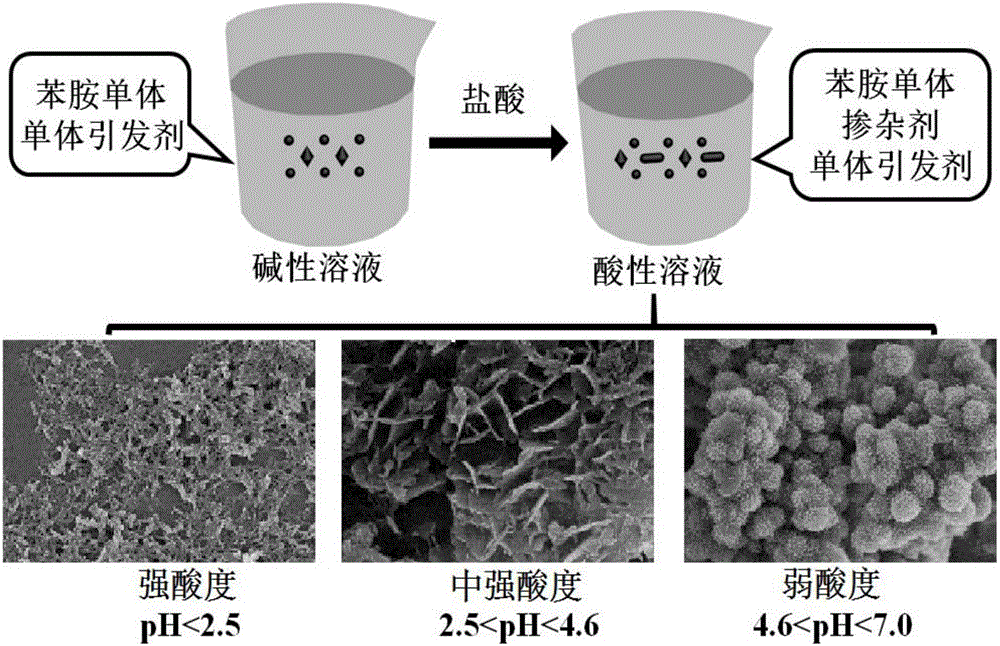

[0038] Preparation of nanostructured polyaniline by a one-pot method (see figure 1 ). First weigh 46.565g aniline (0.5mol) and dissolve in 800mL3.0mol / L ammonia solution, 28.525g ammonium persulfate (0.125mol) dissolve in 200mL3.0mol / L ammonia solution, then mix the two phases uniformly, React at 60°C for 10 minutes to obtain aniline oligomer solution; add 400mL of hydrochloric acid to adjust the reaction system to strong acidity, and its pH value is 0; weigh 279.39g of aniline (3.0mol) and dissolve it to 50mL6.0mol / L In the camphorsulfonic acid solution, 171.15g ammonium persulfate (0.75mol) is dissolved in the 50mL6.0mol / L camphorsulfonic acid solution, then monomer and monomer initiator solution are added in the above-mentioned aniline oligomer solution successively, in React at 60°C for 0.5h; after the reaction, the product is washed several times, filtered with suction, and finally dried in vacuum at low temperature. Observation by scanning electron microscope, prepare...

Embodiment 2

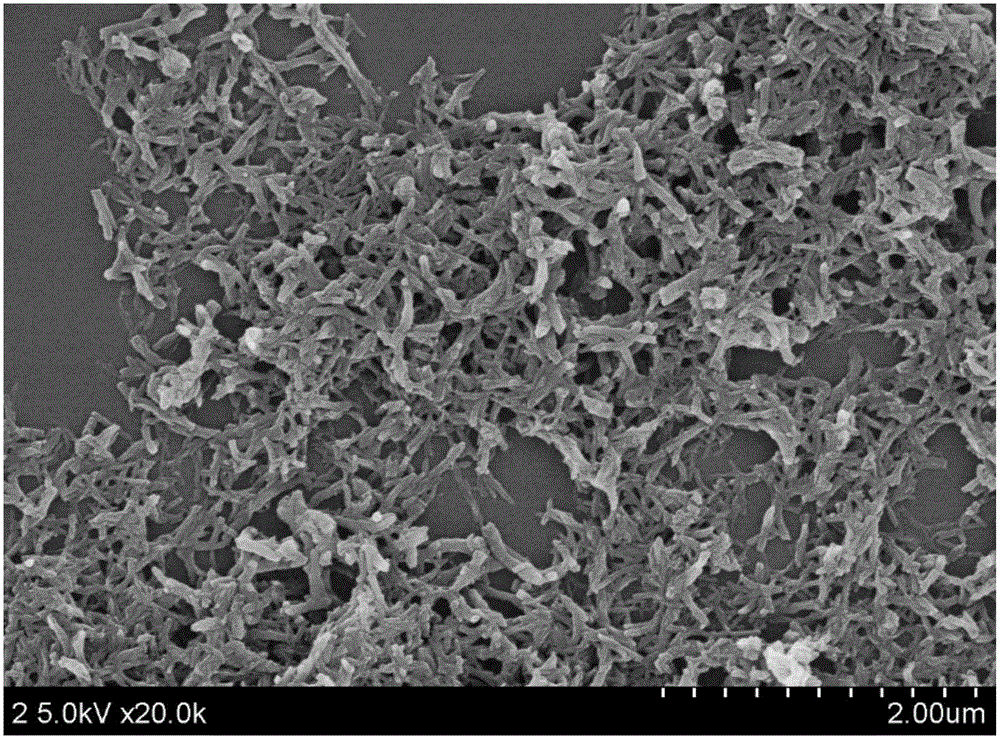

[0040] First weigh 0.093g aniline (0.001mol) and dissolve it in 800mL3.0mol / L ammonia solution, and dissolve 0.228g ammonium persulfate (0.001mol) into 200mL3.0mol / L ammonia solution, then mix the two phases uniformly, React under ice-water bath conditions for 6 hours to obtain aniline oligomer solution; add 330mL hydrochloric acid to adjust the reaction system to a moderately strong acidity, and the pH value is about 3.0; weigh 13.98g aniline (0.15mol) and dissolve it to 100mL6.0mol / In L acetic acid solution, 486.54g ferric chloride (1.8mol) is dissolved in 70mL6.0mol / L acetic acid solution, then successively monomer and monomer initiator solution are added in the aniline oligomer solution, under ice-water bath condition The reaction was carried out for 24 hours; after the reaction, the product was washed several times, filtered with suction, and finally dried in vacuum at low temperature. Observation by scanning electron microscope, prepared polyaniline is sheet structure (...

Embodiment 3

[0042] First weigh 15.832g aniline (0.17mol) and dissolve in the ammonia solution of 800mL0.1mol / L, 556.060g iron sulfate (2.0mol) dissolve in the ammonia solution of 200mL0.1mol / L, then the two phases are uniformly mixed, in React at 60°C for 10 minutes to obtain aniline oligomer solution; add 60mL of hydrochloric acid to adjust the reaction system to weak acidity, and the pH value is about 4.0; weigh 279.39g of aniline (3.0mol) and dissolve it in 100mL of 0.1mol / L sulfuric acid / sulfosalicylic acid solution, 300mL30% hydrogen peroxide (3.0mol) was dissolved in 40mL0.1mol / L sulfuric acid / sulfosalicylic acid solution, and then the monomer and monomer initiator solution were added to the aniline The oligomer solution was reacted for 24 hours in an ice-water bath; after the reaction, the product was washed several times, filtered with suction, and finally dried in vacuum at low temperature. Observed by scanning electron microscope, the prepared polyaniline is a petal-like str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com