Low-temperature-resistant lubricating oil and preparation method thereof

A technology of lubricating oil and low temperature resistance, applied in the field of lubricating oil, can solve the problems of lubricating oil solidification, restricting the application of motor industry, etc., and achieve the effect of improving life expectancy and good low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

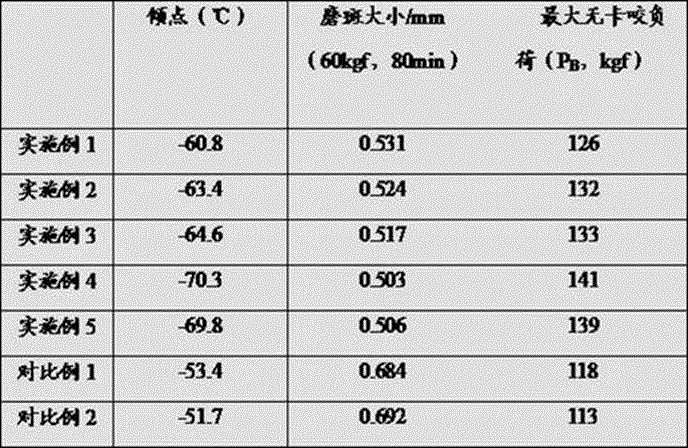

Examples

Embodiment 1

[0026] A low-temperature-resistant lubricating oil described in this embodiment includes the following components in parts by weight: 100 parts of base oil, 5 parts of nano-tin powder, 16 parts of 1-phenylcyclopentane carboxylic acid, and 4 parts of nano-vanadium hydroxide , 6 parts of silicotungstic acid, 3 parts of calcium chloride, 13 parts of bis(cyclopentadiene) hafnium dichloride, 10 parts of sulfated castor oil, 6 parts of calcium gluconate, 3 parts of sodium dodecylbenzenesulfonate , 5 parts of dandelion extract, 7 parts of barium dinonyl naphthalene sulfonate, 4 parts of glycolic acid, 5 parts of ethoxylated trisiloxane, 3 parts of monolauryl phosphate, 10352 parts of antioxidant, acrylic acid 23 parts of triol;

[0027] The base oil comprises polyalphaolefin, castor oil and polyethylene glycol in a weight ratio of 5:2:4.

[0028] The dandelion extract is obtained by crushing and sieving dried dandelion, extracting with 80% ethanol under reflux for 4 hours, and conce...

Embodiment 2

[0036] A low-temperature-resistant lubricating oil described in this embodiment includes the following components in parts by weight: 100 parts of base oil, 11 parts of nano-tin powder, 21 parts of 1-phenylcyclopentane carboxylic acid, and 8 parts of nano-vanadium hydroxide , 14 parts of silicotungstic acid, 9 parts of calcium chloride, 19 parts of bis(cyclopentadiene) hafnium dichloride, 15 parts of sulfated castor oil, 10 parts of calcium gluconate, 8 parts of sodium dodecylbenzenesulfonate , 12 parts of dandelion extract, 14 parts of barium dinonyl naphthalene sulfonate, 11 parts of glycolic acid, 14 parts of ethoxylated trisiloxane, 9 parts of monolauryl phosphate, 1035-6 parts of antioxidant , 38 parts of glycerol;

[0037] The base oil comprises polyalphaolefin, castor oil and polyethylene glycol in a weight ratio of 5:2:4.

[0038] The dandelion extract is obtained by crushing and sieving dried dandelion, extracting with 80% ethanol under reflux for 4 hours, and concen...

Embodiment 3

[0046] A low-temperature-resistant lubricating oil described in this embodiment includes the following components in parts by weight: 100 parts of base oil, 8 parts of nano-tin powder, 18 parts of 1-phenylcyclopentane carboxylic acid, and 6 parts of nano-vanadium hydroxide , 10 parts of silicotungstic acid, 6 parts of calcium chloride, 15 parts of bis(cyclopentadiene) hafnium dichloride, 12 parts of sulfated castor oil, 8 parts of calcium gluconate, 6 parts of sodium dodecylbenzenesulfonate , 8 parts of dandelion extract, 11 parts of barium dinonyl naphthalene sulfonate, 8 parts of glycolic acid, 10 parts of ethoxylated trisiloxane, 6 parts of monolauryl phosphate, 10354 parts of antioxidant, acrylic acid 30 parts of triol;

[0047] The base oil comprises polyalphaolefin, castor oil and polyethylene glycol in a weight ratio of 5:2:4.

[0048] The dandelion extract is obtained by crushing and sieving dried dandelion, extracting with 80% ethanol under reflux for 4 hours, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com