Steel mesh and fiber reinforced integrated foam concrete lightweight wallboard and manufacturing method thereof

A foamed concrete, fiber-reinforced technology, applied in the direction of walls, ceramic products, other household appliances, etc., to achieve the effect of small foam diameter, simple production process and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the embodiments do not limit the present invention in any form.

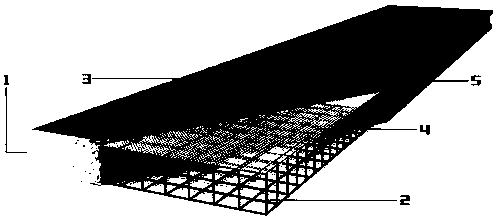

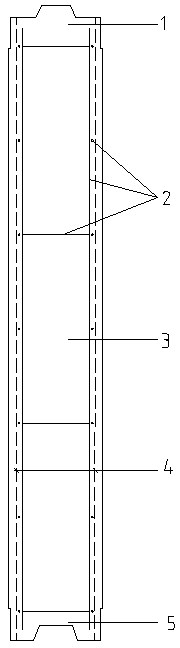

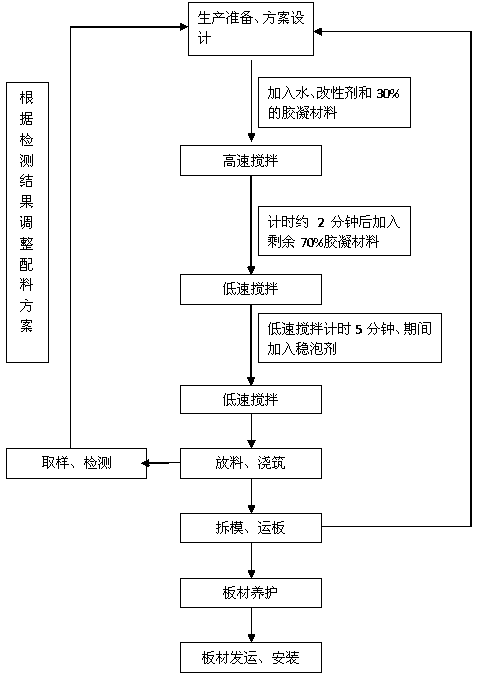

[0029] see figure 1 , figure 2 , a steel wire mesh and fiber reinforced integrated foam concrete lightweight wallboard, its structure is: 3D steel mesh 2 wrapped inside the foam concrete 3, 3D steel mesh 2 has alkali-resistant glass fiber mesh cloth 4 on the surface, 3D steel mesh 2 1. The alkali-resistant glass fiber mesh cloth 4 is integrally cast and formed by the foam concrete 3 slurry; the tenon 1 and the matching groove 5 are reserved on both sides of the plate respectively, and the tenon 1 and the groove 5 are trapezoidal. The thickness of the trapezoid is 15-20mm, the length of the upper side is 20mm, and the length of the lower side is 40mm; the diameter of the steel wire of the 3D steel wire mesh 2 is 1.5-3mm, and the distance between the steel wires is 50-100mm.

[0030]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com