Method for preparing scintillation crystal detection unit

A technology of crystal units and scintillation crystals, applied in the field of radiation detection, to achieve the effects of improving transmission efficiency, reducing losses, avoiding absorption and reducing reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

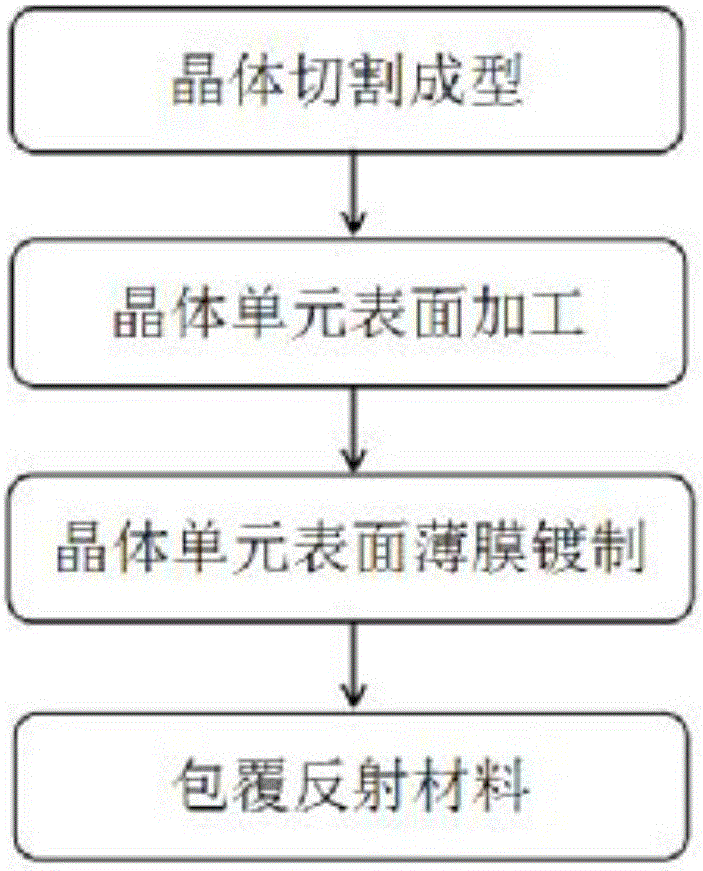

[0044] Example 1, such as figure 1 As shown, it includes crystal cutting and forming steps, crystal unit surface processing steps, crystal unit surface film coating steps and reflective material coating steps:

[0045] (1) Crystal cutting and molding step, cutting the scintillation crystal into crystal units with the same shape and size, the crystal unit is a strip crystal, the strip crystal is a quadrangular prism, and its cross section is a square, and the scintillation The crystal material is yttrium lutetium silicate;

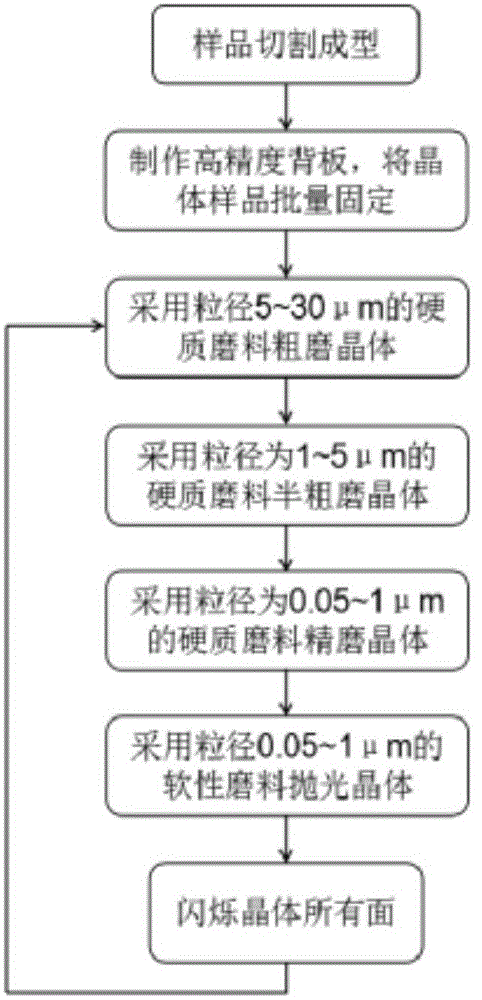

[0046] (2) The surface processing step of the crystal unit, including the following sub-steps:

[0047] (2.1) Backplane heating:

[0048] Use a constant temperature control heating device to heat the back plate, and the temperature is controlled at 80°C; spin-coat wax on the surface of the back plate;

[0049] The back plate is a plate made of fused silica glass, the shape is circular, the upper and lower sides of the back plate are parallel planes, and ...

Embodiment 2

[0065] Embodiment 2, including the crystal cutting and forming step, the crystal unit surface processing step, the crystal unit surface film coating step and the reflective material coating step:

[0066] (1) Crystal cutting and molding step, cutting the scintillation crystal into crystal units with the same shape and size, the crystal unit is a strip crystal, the strip crystal is a quadrangular prism, and its cross section is a square, and the scintillation The crystal is lutetium silicate;

[0067] (2) The surface processing step of the crystal unit, including the following sub-steps:

[0068] (2.1) Backplane heating:

[0069] Use a constant temperature control heating device to heat the back plate, and the temperature is controlled at 120°C; spin-coat epoxy resin on the surface of the back plate, the back plate is made of fused silica glass, the shape is circular, and the upper and lower sides of the back plate are parallel surfaces. The flatness of the upper and lower su...

Embodiment 3

[0085] Embodiment 3, including the crystal cutting and forming step, the crystal unit surface processing step, the crystal unit surface film coating step and the reflective material coating step:

[0086] (1) Crystal cutting and molding step, cutting the scintillation crystal into crystal units with the same shape and size, the crystal unit is a strip crystal, the strip crystal is a quadrangular prism, and its cross section is a square, and the scintillation The crystal is gadolinium lutetium silicate;

[0087] (2) The surface processing step of the crystal unit, including the following sub-steps:

[0088] (2.1) Backplane heating:

[0089] Use a constant temperature control heating device to heat the back plate, and the temperature is controlled at 120°C; spin-coat epoxy resin on the surface of the back plate, the back plate is made of fused silica glass, the shape is circular, and the upper and lower sides of the back plate are parallel surfaces. The flatness of the upper a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com