Method for preparing photoelectric absorption and conversion layers of copper, indium, gallium and selenium thin film solar cells

A solar cell, copper indium gallium selenide technology, applied in coatings, circuits, photovoltaic power generation, etc., can solve the problems of easy mutual interference of evaporation sources, complex evaporation source design, expensive targets, etc., to avoid the complexity of process and equipment , Facilitate large-scale production, facilitate the effect of popularization and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

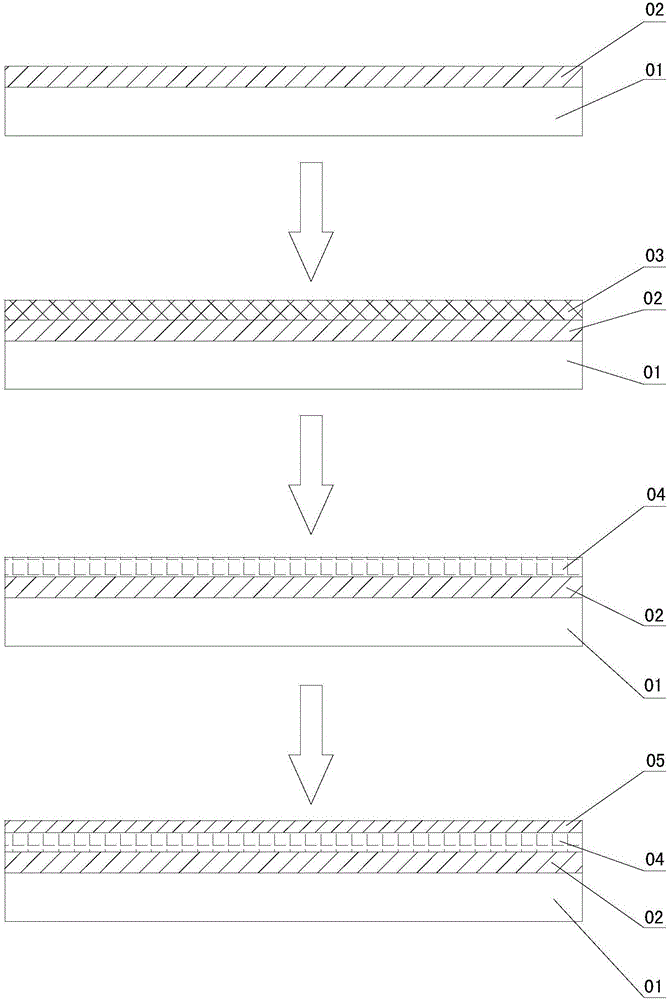

[0020] choose first figure 1 As shown in the substrate, the substrate includes a plate-shaped material 01 with a flat surface, and a layer of molybdenum film 02 deposited on the plate-shaped material. As a preferred method for manufacturing thin-film solar cells, the plate material 01 may be flat glass or a treated stainless steel plate or a treated polyimide plate. The substrate described above is an existing structure. After the substrate selection is completed, the following implementation steps are carried out:

[0021] 1. Sputter a layer of copper-gallium alloy thin film with a thickness of 0.2-2.5 μm on the substrate by vacuum sputtering. The specific method is to place the above-mentioned substrate in a vacuum sputtering chamber provided with a copper-gallium alloy target, and deposit a layer of copper-gallium alloy film by physical sputtering. The copper-gallium alloy film of the copper-gallium alloy film The two elements of gallium and copper come from the same cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com