Woody plant feed additive for livestock and poultry, and preparation method of feed additive

A technology of feed additives and woody plants, applied in the field of woody plant feed additives and its preparation, can solve problems such as high cost, achieve the effects of promoting absorption, shortening the slaughter cycle, and improving gastrointestinal function and immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A woody plant feed additive for livestock and poultry, comprising the following raw materials in parts by weight: 40 parts of seabuckthorn branches, 10 parts of ginkgo leaves, 10 parts of wolfberry branches, 7 parts of alfalfa grass, 15 parts of tea residue, and 10 parts of pine needles;

[0023] The woody plant feed additive for livestock and poultry is prepared as follows:

[0024] (1) drying each raw material until the moisture content is less than 10%, and coarsely crushing to 10-20 mesh;

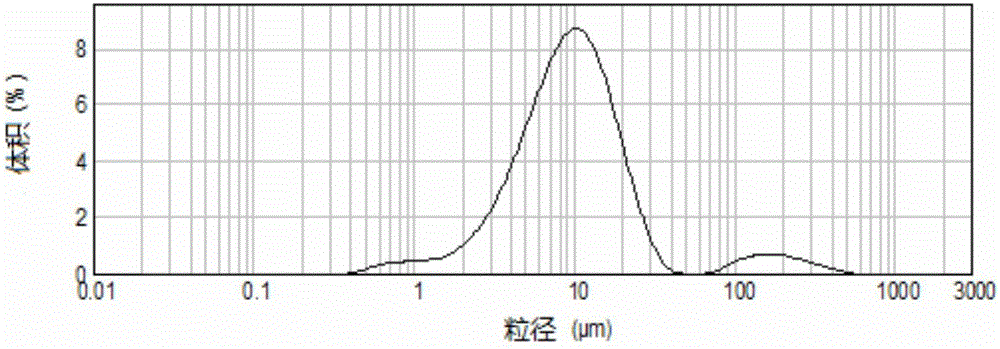

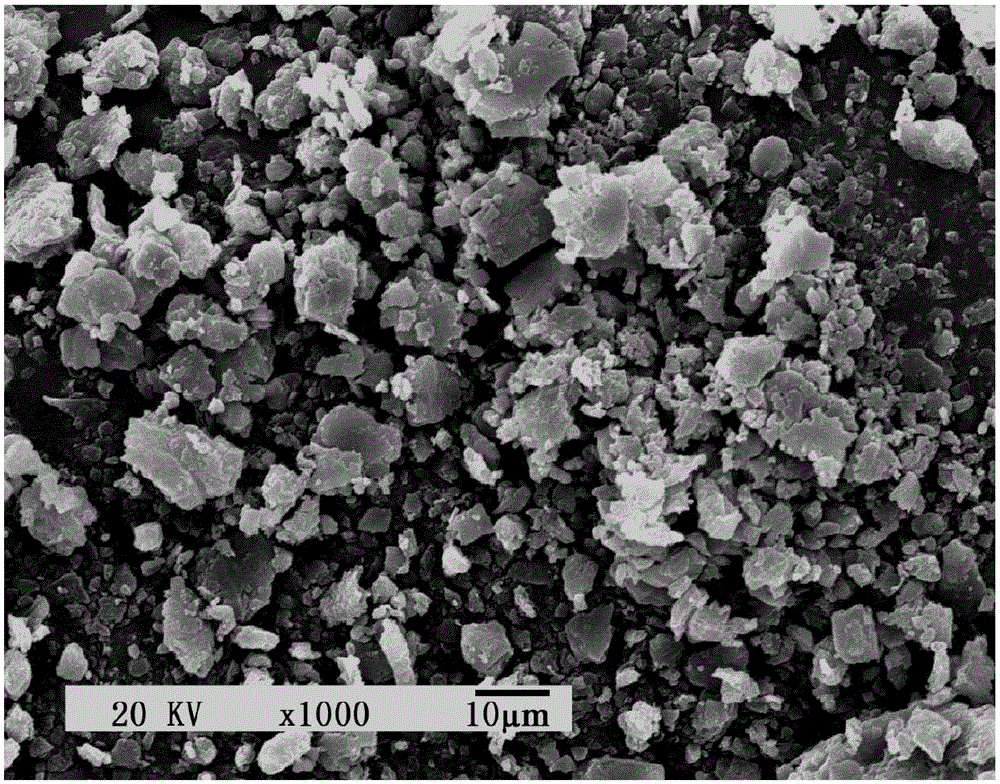

[0025] (2) Take each raw material according to the above parts by weight, mix them uniformly, and finely grind them for 15 minutes on a planetary ball mill with a cooling system to obtain an ultrafine powder with a particle size of 1-50 microns, and keep the temperature of the fine grinding process lower than 40 ℃, where the ball-to-material ratio of the ball mill is 10;

[0026] (3) After the finely ground ultrafine powder is cooled to room temperature, it is packaged and store...

Embodiment 2

[0030] In this example, Sanhuang chickens were fed with the additive of the present invention in the diet, and its growth-promoting effect and safety were investigated through relative weight gain rate, feed conversion rate and liver and kidney biochemical indicators.

[0031] The specific steps include: 120 25-day-old three-yellow chickens are randomly divided into 12 cages, 10 birds per cage, wherein 1-6 cages are the control group, fed with basic feed, and 7-12 cages are the test group, fed every 100 parts by weight The basic feed is evenly mixed into the mixed feed of 10 parts by weight of the feed additive of the present invention (prepared in Example 1). The control group and the test group were raised in the same chicken house, with free access to food and water, and were fed for 30 days.

[0032] During the feeding period, the feed intake and health status of the chickens were observed every day. At the end of the test, the weight of each cage chicken was weighed on an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com