Functionally-graded wear-resistant iron-based composite material and preparation method thereof

An iron-based composite material and functionally gradient technology, applied in the field of functionally graded composite materials, can solve problems such as inappropriateness, and achieve the effects of stable product quality, not easy to break and peel off, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

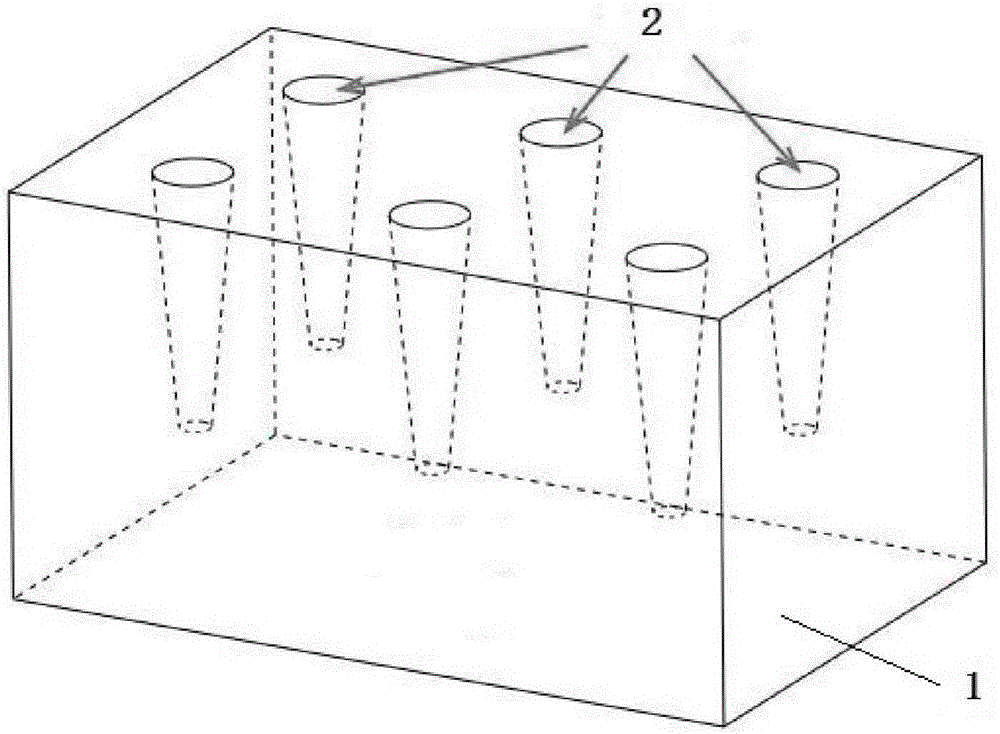

[0021] A method for preparing a functionally graded wear-resistant iron-based composite material, comprising the following steps:

[0022] Step 1, designing and preparing a graphite mold, the shape of the inner cavity is conical, the cone angle is 30°, and the bottom diameter is 10mm;

[0023] Step 2, mechanically mixing WC ceramic particles with a particle size of 100 mesh and iron powder using absolute ethanol to obtain a mixture,

[0024] Step 3: Fill the above mixture into a graphite mold, dry it at 100°C, then put the mold and the mixed particles into a vacuum sintering furnace, and sinter at 1450°C with a vacuum degree of 10 -1 Pa. The sintering time is 45 minutes. The metal powder bonds the ceramic particles together. After cooling, the mold is opened to take out the formed preform;

[0025] Step 4, put the conical preform on the bottom of the mold, keeping a certain distance;

[0026] Step 5 Melt 45 steel in an intermediate frequency induction furnace, start the vac...

Embodiment 2

[0029] A method for preparing a functionally graded wear-resistant iron-based composite material, comprising the following steps:

[0030] Step 1, designing and preparing a graphite mold, the shape of the inner cavity is conical, the cone angle is 45°, and the bottom diameter is 15mm;

[0031] Step 2, mechanically mixing WC ceramic particles with a particle size of 100 mesh and iron powder using absolute ethanol to obtain a mixture,

[0032] Step 3: Fill the above mixture into a graphite mold, dry it at 100°C, then put the mold and the mixed particles into a vacuum sintering furnace, and sinter at 1450°C with a vacuum degree of 10 -1 Pa. The sintering time is 45 minutes. The metal powder bonds the ceramic particles together. After cooling, the mold is opened to take out the formed preform;

[0033] Step 4, put the conical preform on the bottom of the mold, keeping a certain distance;

[0034] Step 5 Melt the 40Cr steel in an intermediate frequency induction furnace, start t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com