Electrolyte and lithium ion battery containing electrolyte

An electrolyte and lithium salt technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as high viscosity, impact on battery performance, difficulty in infiltration of pole pieces and diaphragms, etc., to improve thermal stability and thermal stability Good performance and improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

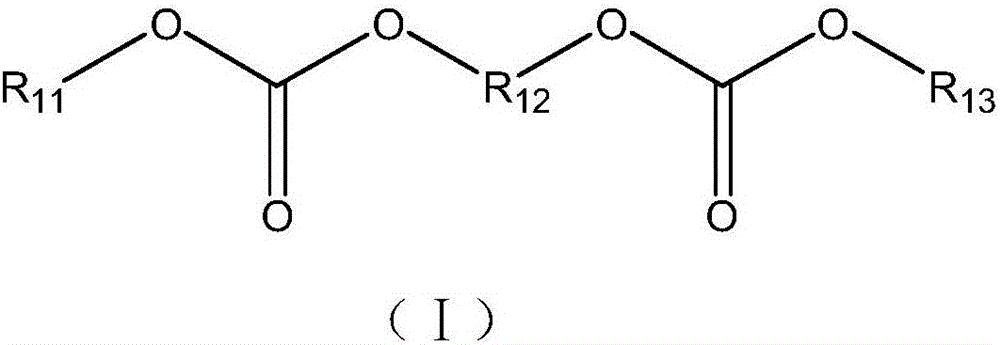

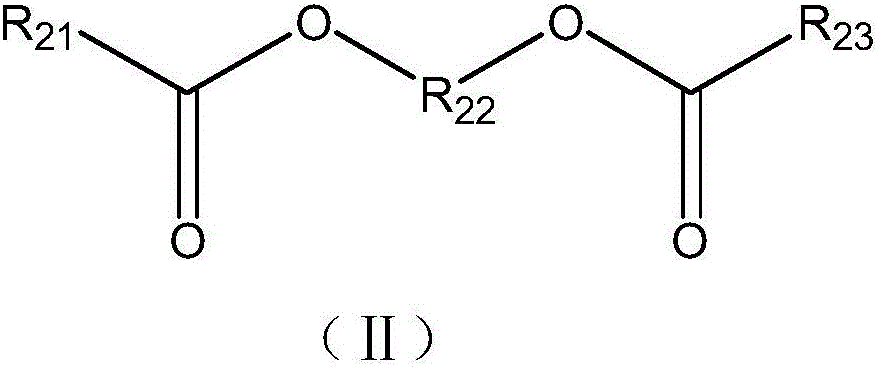

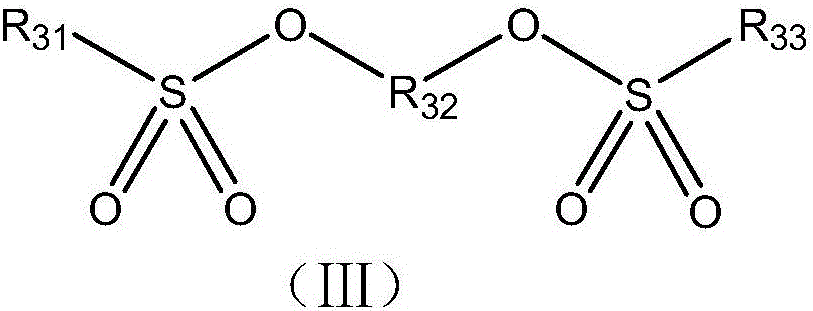

Method used

Image

Examples

Embodiment 1

[0169] The preparation of embodiment 1 lithium ion battery

[0170] In Comparative Example 1 # ~6 # As in Examples 1-10, the lithium-ion battery (hereinafter referred to as the battery) is prepared according to the following method:

[0171] (1) Preparation of positive electrode sheet

[0172] Lithium cobalt oxide (LiCoO 2 ), the binder polyvinylidene fluoride, and the conductive agent acetylene black are LiCoO in weight ratio 2 : polyvinylidene fluoride: acetylene black = 96:2:2 for mixing, then add N-methylpyrrolidone (NMP), then stir under the action of a vacuum mixer until the system becomes uniform and transparent, and obtain the positive electrode slurry; the positive electrode slurry The material was uniformly coated on an aluminum foil with a thickness of 12 μm; the aluminum foil was dried at room temperature and then transferred to an oven at 120° C. for 1 hour, and then cold-pressed and cut to obtain positive electrodes.

[0173] (2) Preparation of negative elec...

Embodiment 2

[0212] Electrolyte and lithium-ion battery were prepared according to the method of Example 1, the difference being that the composition of additives in the electrolyte was as shown in Table 4;

[0213] Table 4

[0214]

[0215]

[0216] The lithium-ion battery was prepared by using the electrolyte in Table 4, and the properties of the prepared battery were similar to those of Example 1, and will not be repeated due to space limitations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com