Carbon tube microcapsule catalyst and its preparation method and use

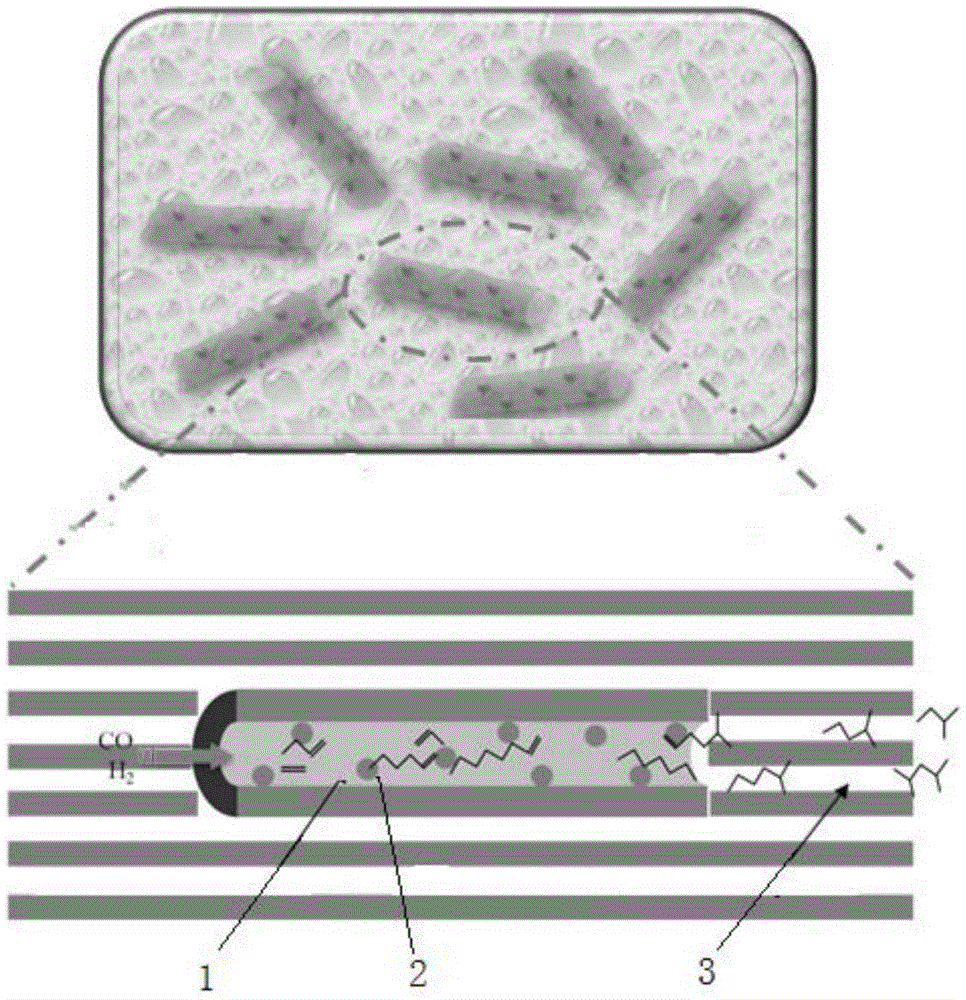

A catalyst and microcapsule technology, which is applied in the field of carbon tube microcapsule catalyst and its preparation, can solve the problems of large molecular diffusion resistance, low mechanical strength, low metal dispersion, etc., to prevent the loss of active components of the catalyst and maintain mechanical stability Good, excellent structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of carbon tube microcapsule catalyst, comprising the steps of:

[0042] 1) Preparation of Co / CNTs precursor catalyst by over-volume impregnation method:

[0043] The carbon nanotubes were treated in 65wt% nitric acid at 120°C for 14h, washed with water to pH = 7, and dried; then treated with Co(NO 3 ) 2 ·6H 2 O is impregnated with a Co source, the active metal Co loading is 10wt%, vacuum treatment for 1h, drying at 120°C for 12h, and calcination at 350°C for 3h to obtain a precursor particle catalyst; the precursor particle catalyst is crushed into powder.

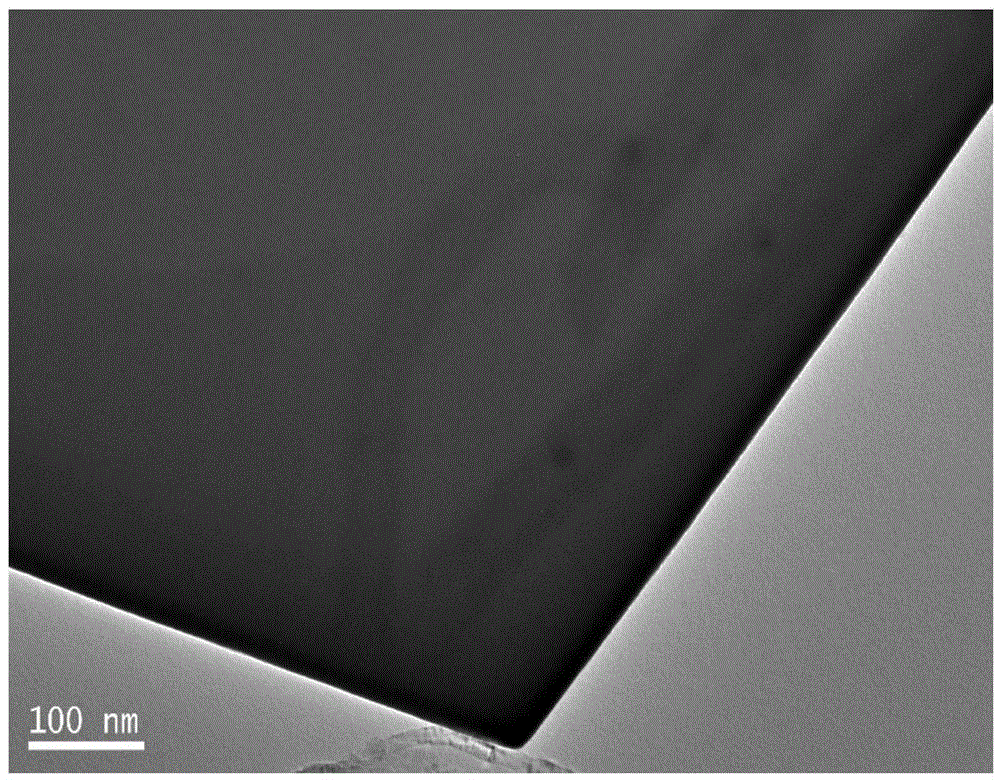

[0044] 2) Orthoethyl silicate (TEOS) is the silicon source, aluminum nitrate (Al(NO 3 ) 3 ) is the aluminum source, and tetrapropylammonium hydroxide (abbreviation: TPAOH) is the template agent; firstly, the active carbon nanotube powder, tetrapropylammonium hydroxide, aluminum nitrate, and ethanol are mixed by ultrasonic vibration, and dried after ultrasonic vibration; secondly, the Tetrap...

Embodiment 2

[0052] A kind of preparation method of carbon tube microcapsule catalyst, repeat embodiment 1, its difference is only in the treatment mode of carbon tube in Co / CNTs precursor catalyst, be about to carbon nanotube in 65wt% nitric acid 120 ℃ process 14h instead The carbon nanotubes were treated in 35wt% nitric acid at 120°C for 14h.

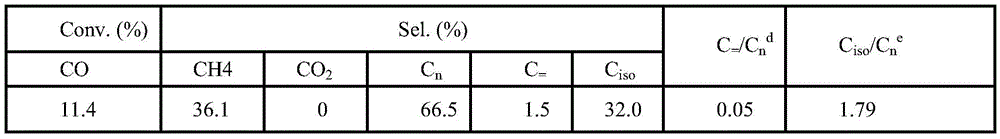

[0053] The obtained carbon tube microcapsule catalyst was used for the performance test of the fixed-bed Fischer-Tropsch synthesis reaction.

[0054] The evaluation of the Fischer-Tropsch reaction activity of the catalyst is the same as in Example 1, and the reaction results are shown in the table below.

[0055]

[0056] C n is paraffin; C = is an alkene; C iso Isoparaffins; C = / C n d for C 2 + Ratio of alkenes to paraffins; C iso / C n e for C 4 + Ratio of isoparaffins to paraffins

Embodiment 3

[0058] A method for preparing a carbon tube microcapsule catalyst, repeating Example 1, the difference is only in the cobalt source impregnation method, that is, the over-volume impregnation method is changed to the equal-volume impregnation method.

[0059] The obtained carbon tube microcapsule catalyst was used for the performance test of the fixed-bed Fischer-Tropsch synthesis reaction.

[0060] The evaluation of the Fischer-Tropsch reaction activity of the catalyst is the same as in Example 1, and the reaction results are shown in the table below.

[0061]

[0062] C n is paraffin; C = is an alkene; C iso Isoparaffins; C = / C n d for C 2 + Ratio of alkenes to paraffins; C iso / C n e for C 4 + Ratio of isoparaffins to paraffins

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com