2D carbon/silicon-silicon carbide composite material pin preparation method and preparation method and structure of 2D carbon/silicon-silicon carbide composite material pin preform

A technology of composite materials and silicon carbide, which is applied in the field of corrosion-resistant and oxidation-resistant composite materials, high temperature resistance, preparation and processing of ceramic matrix composite materials, and high strength. It can solve unstable product performance, long production cycle, and high cost. problems, to achieve the effect of uniform force, improved mechanical properties, and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

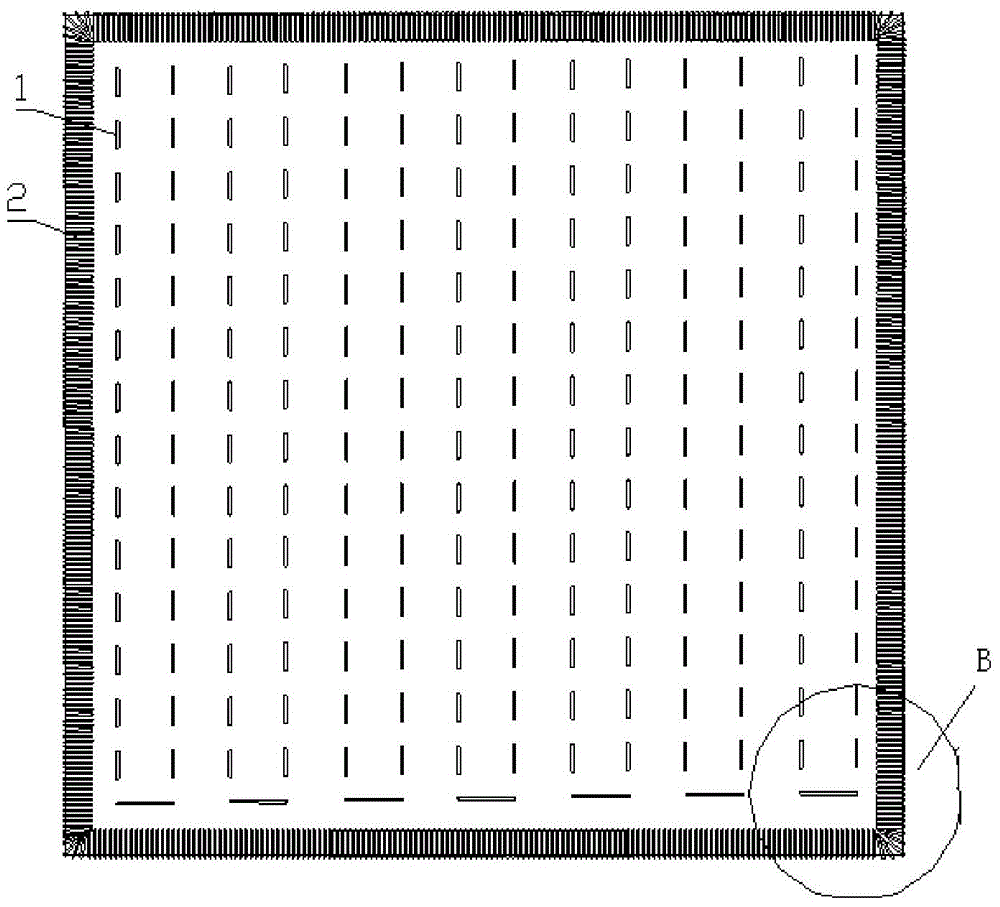

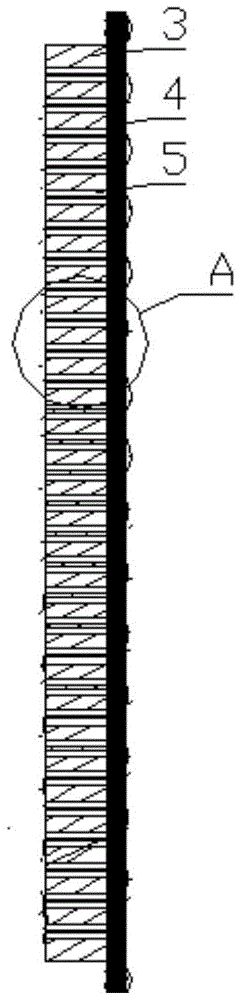

[0051] Such as Figure 2-3 As shown, the two-dimensional carbon / silicon-silicon carbide composite pin prefabricated body of the present invention includes a multilayer two-dimensional carbon cloth, and the included angle between the corresponding fibers of two adjacent two-dimensional carbon cloths in the multilayer two-dimensional carbon cloth is 45°, the two-dimensional carbon / silicon-silicon carbide composite pin preform also includes a sewing structure, the sewing structure includes a plurality of U-shaped fibers distributed in a square matrix, and the plurality of U-shaped fibers are obtained from the multi-layer two-dimensional carbon cloth One side vertically penetrates multiple layers of two-dimensional carbon cloth. The four sides of the multi-layer two-dimensional carbon cloth are locked with carbon fibers, and sometimes a U-shaped fiber is provided at the end of two adjacent rows of U-shaped fibers in the square matrix. The preparation method of the two-dimensional...

Embodiment 1

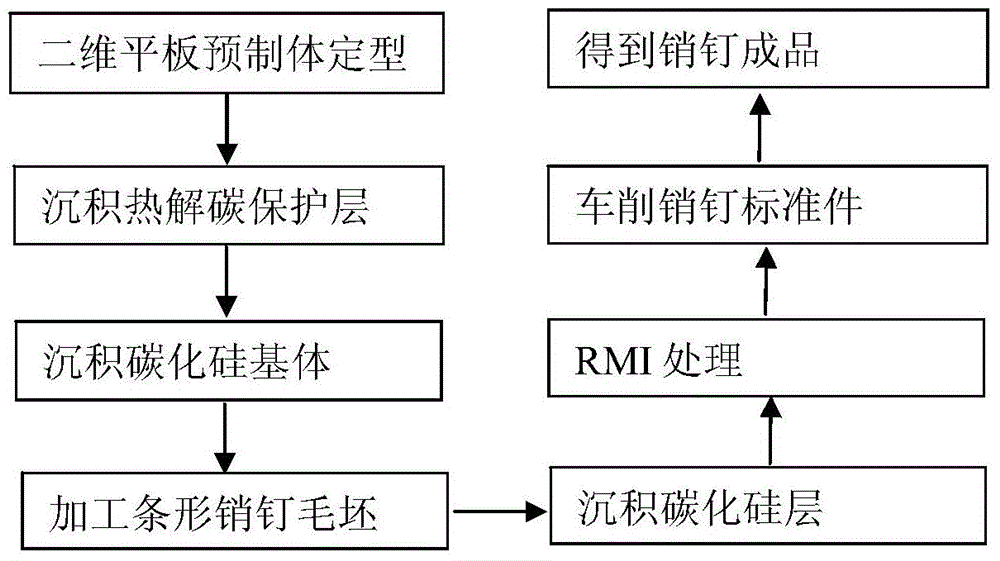

[0059] This embodiment is a method for preparing a two-dimensional carbon / silicon-silicon carbide composite pin, and its specific process is:

[0060] Step 1, making a two-dimensional flat plate preform. Use two-dimensional carbon cloth to lay alternately layer by layer in the direction of flat laying (0°) and oblique laying (45°) (the thickness is guaranteed to be greater than the diameter of the pin and a processing allowance is left), and the surface to be used is punched (8~15× 8 ~ 15mm arrangement) graphite plate flattened the carbon cloth, the bow frame is fixed on the bracket, carbon fiber is used to pass through each hole, and the carbon cloth is vertically sewn to form a two-dimensional flat plate prefabricated body.

[0061] Step 2, depositing a pyrolytic carbon interface layer. The pyrolytic carbon protective layer is infiltrated inside the two-dimensional flat plate preform through a deposition furnace. The process conditions are: the deposition temperature is 700...

Embodiment 2

[0068] Step 1, making a two-dimensional flat plate preform. Use two-dimensional carbon cloth to lay alternately layer by layer in the direction of flat laying (0°) and oblique laying (45°) (the thickness is guaranteed to be greater than the diameter of the pin and a processing allowance is left), and the surface to be used is punched (8~15× 8 ~ 15mm arrangement) graphite plate flattened the carbon cloth, the bow frame is fixed on the bracket, carbon fiber is used to pass through each hole, and the carbon cloth is vertically sewn to form a two-dimensional flat plate prefabricated body.

[0069] Step 2, depositing a pyrolytic carbon interface layer. The pyrolytic carbon protective layer is infiltrated inside the two-dimensional flat plate preform through a deposition furnace. The process conditions are: the deposition temperature is 800°C, the deposition furnace is vacuumed to 3kPa, and the flow rate is 4L / min of propylene gas as the deposition gas, 8L / min min of Ar gas was use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com