Method for preparing triethyl phosphite

A technology of triethyl phosphite and absolute ethanol, which is applied in the chemical industry, can solve the problems of long production cycle, high discharge of "three wastes" and difficult wastewater treatment, so as to improve the purity and conversion rate, avoid the problem of wastewater discharge, Conducive to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

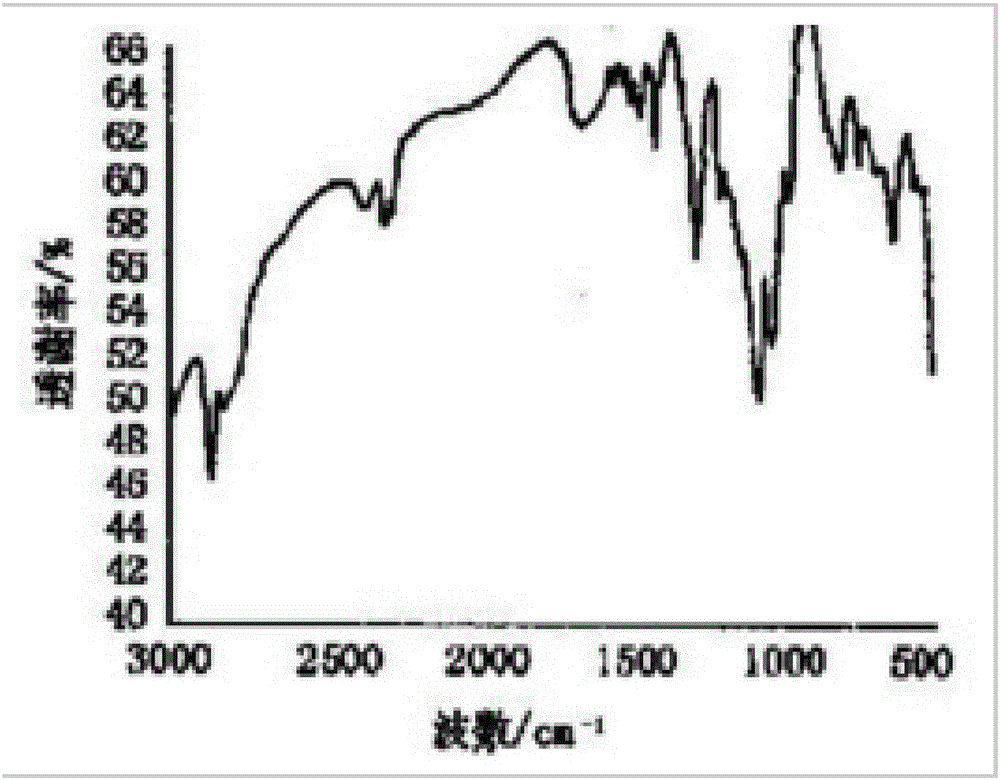

Image

Examples

Embodiment 1

[0019] A kind of preparation method of triethyl phosphite proposed by the present invention comprises the following steps,

[0020] S1: Add 46g of absolute ethanol, 100ml of toluene, 6.5g of di-n-butylamine to a 500ml reactor equipped with electric stirring, thermometer, constant pressure dropping funnel, acid absorption system, vacuum system and condenser, and start the stirring device , mix the materials evenly, use an ice-water bath to lower the temperature of the system to 20°C, and observe the temperature displayed on the thermometer all the time, and control the reaction temperature between 15-20°C by adding ice cubes to the ice-water bath, and rotate The plunger of the constant pressure dropping funnel adjusts the dropping speed, so that 45g of phosphorus trichloride solution in the constant pressure dropping funnel is slowly added dropwise to the reactor. After 1 hour of dropping, the temperature of the reaction system is raised to 50°C by a heater in 30 minutes. ;

...

Embodiment 2

[0024] A kind of preparation method of triethyl phosphite proposed by the present invention comprises the following steps,

[0025] S1: In a 500ml reactor equipped with electric stirring, thermometer, constant pressure dropping funnel, acid absorption system, vacuum system and condenser, add absolute ethanol 46g, toluene 100ml, triethylamine 5g, open the stirring device, make Mix the materials evenly, use an ice-water bath to lower the temperature of the system to 20°C, and observe the temperature displayed on the thermometer all the time, and control the reaction temperature between 15-20°C by adding ice cubes to the ice-water bath, and rotate at a constant pressure The plunger of the dropping funnel adjusts the dropping speed so that 45g of phosphorus trichloride solution in the constant pressure dropping funnel is slowly added dropwise to the reactor, and the dropping is completed within 1 hour, and the temperature of the reaction system is raised to 50°C within 30 minutes; ...

Embodiment 3

[0029] A kind of preparation method of triethyl phosphite proposed by the present invention comprises the following steps,

[0030] S1: In a 500ml reactor equipped with electric stirring, thermometer, constant pressure dropping funnel, acid absorption system, vacuum system and condenser, add 46g of absolute ethanol, 100ml of toluene, 8g of di-n-butylamine, start the stirring device, Mix the materials evenly, use an ice-water bath to lower the system temperature to 20°C, and observe the temperature displayed on the thermometer all the time, and control the reaction temperature between 15 and 20°C by adding ice cubes to the ice-water bath, and rotate it constantly Press the plunger of the dropping funnel to adjust the dropping speed, so that 45g of phosphorus trichloride solution in the constant pressure dropping funnel is slowly added dropwise to the reactor, after 0.6h the dropping is completed, and the temperature of the reaction system is raised to 50°C within 30min;

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com