A kind of concrete viscosity modifier and preparation method thereof

A viscosity modifier and concrete technology, applied in the field of building materials, can solve the problems of precipitation and delamination, affecting the fluidity of concrete, setting time strength and plastic accommodation, etc. Structured novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of high-efficiency and low-cost concrete viscosity modifier, comprising the following steps:

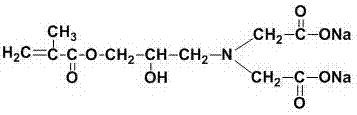

[0020] (1) Add 266g (2mol) of iminodiacetic acid (2mol), 160g (4mol) of sodium hydroxide and 2L of deionized water into a three-neck round bottom flask equipped with a thermometer and an electric stirrer, raise the temperature to 65°C and stir to make it homogeneous Dissolve in water; then slowly add 284g (2mol) of glycidyl methacrylate dropwise, and drop evenly within 4~5 hours, keep stirring at 65°C for 3 hours after the dropwise addition, and obtain a transparent and uniform product after the reaction solution, the concentration of the reaction product GMA-IDA was 1 mol / L.

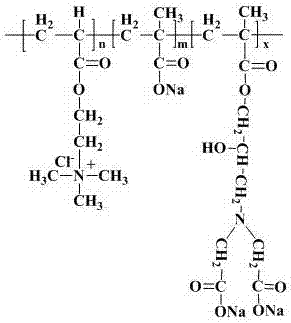

[0021] (2) Take 42.85g of the GMA-IDA solution obtained above, 75g of acryloyloxyethyltrimethylammonium chloride, and 60g of acrylic acid, and prepare an aqueous solution with a mass concentration of 30%. Add water-soluble initiator equivalent to 0.05% of the total amount of materi...

Embodiment 2

[0024] A preparation method of high-efficiency and low-cost concrete viscosity modifier, comprising the following steps:

[0025] (1) Add 266g (2mol) of iminodiacetic acid (2mol), 160g (4mol) of sodium hydroxide and 2L of deionized water into a three-neck round bottom flask equipped with a thermometer and an electric stirrer, raise the temperature to 65°C and stir to make it homogeneous Dissolve in water; then slowly add 284g (2mol) of glycidyl methacrylate dropwise, and drop evenly within 4~5 hours, keep stirring at 65°C for 3 hours after the dropwise addition, and obtain a transparent and uniform product after the reaction solution, the concentration of the reaction product GMA-IDA was 1 mol / L.

[0026] (2) Take 34.28g of the GMA-IDA solution obtained above, 90g of acryloyloxyethyltrimethylammonium chloride, and 48g of methacrylic acid, and prepare an aqueous solution with a mass concentration of 30%, and pass nitrogen gas for 30 minutes at 25°C Finally, add a water-soluble...

Embodiment 3

[0029] A high-efficiency and low-cost concrete viscosity regulator, comprising the following steps:

[0030] (1) Add 266g (2mol) of iminodiacetic acid (2mol), 160g (4mol) of sodium hydroxide and 2L of deionized water into a three-neck round bottom flask equipped with a thermometer and an electric stirrer, raise the temperature to 65°C and stir to make it homogeneous Dissolve in water; then slowly add 284g (2mol) of glycidyl methacrylate dropwise, and drop evenly within 4~5 hours, keep stirring at 65°C for 3 hours after the dropwise addition, and obtain a transparent and uniform product after the reaction solution, the concentration of the reaction product GMA-IDA was 1 mol / L.

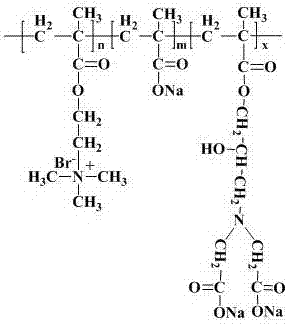

[0031] (2) Take 35.71g of the GMA-IDA solution obtained above, 62.5g of methacryloyloxyethyltrimethylammonium bromide, and 50g of methacrylic acid, and prepare an aqueous solution with a mass concentration of 25%. After 30 minutes of nitrogen gas, add a water-soluble initiator equivalent to 0.08% of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com