Method for preparation of cation membrane for diffusion dialysis with mesoporous silica

A technology of mesoporous silica and diffusion dialysis, which is applied in the field of hybrid cationic membranes for diffusion dialysis, can solve the problem of further improvement of hydroxide radical flux, achieve improved alkali recovery efficiency, simple method, and improved compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

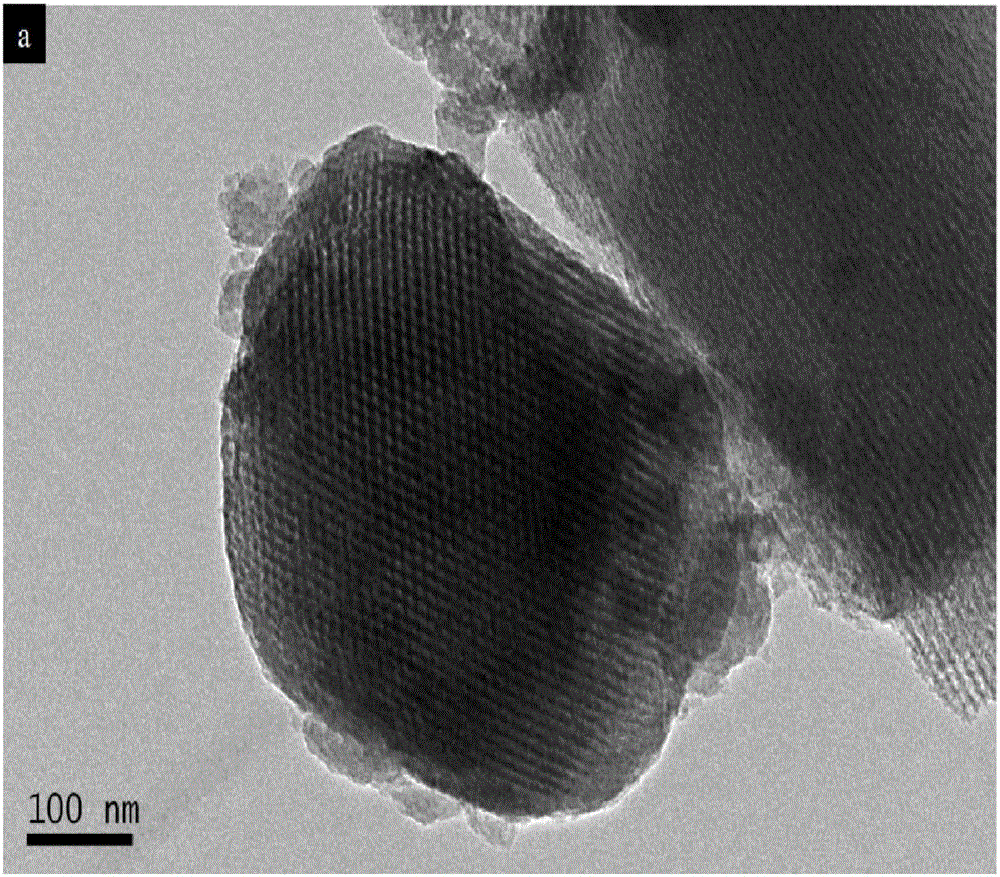

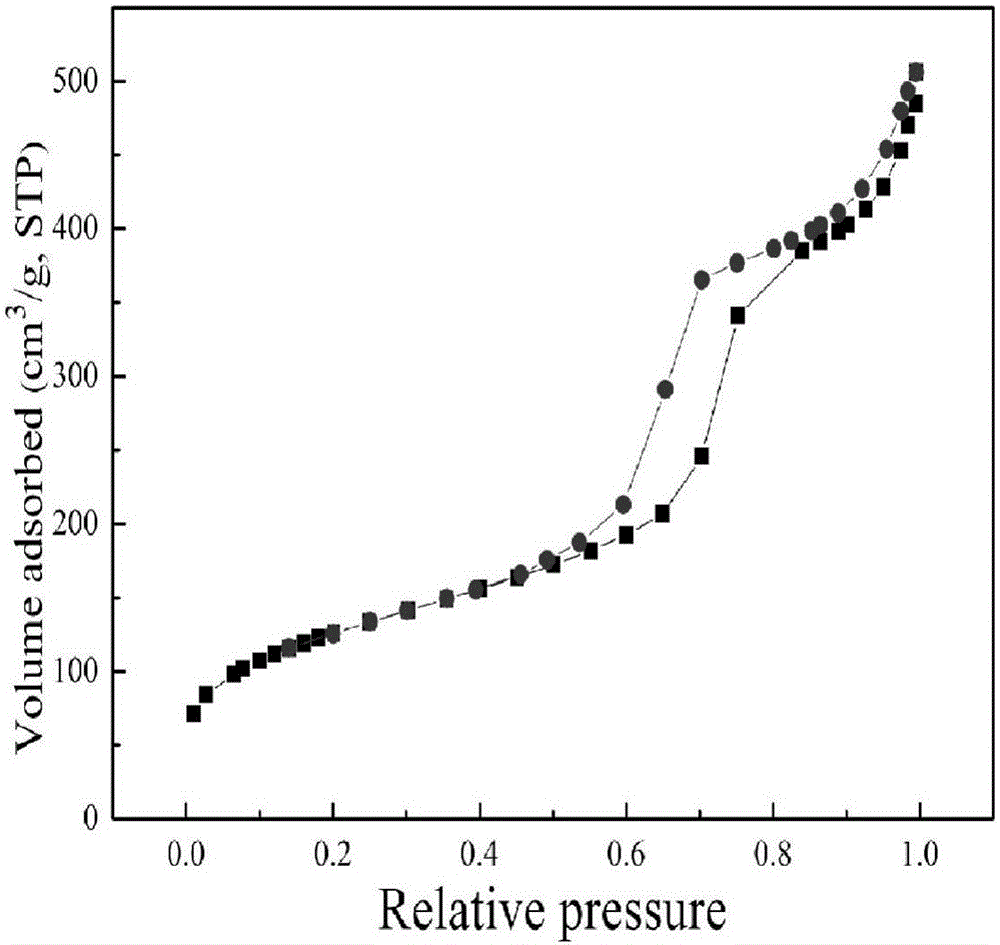

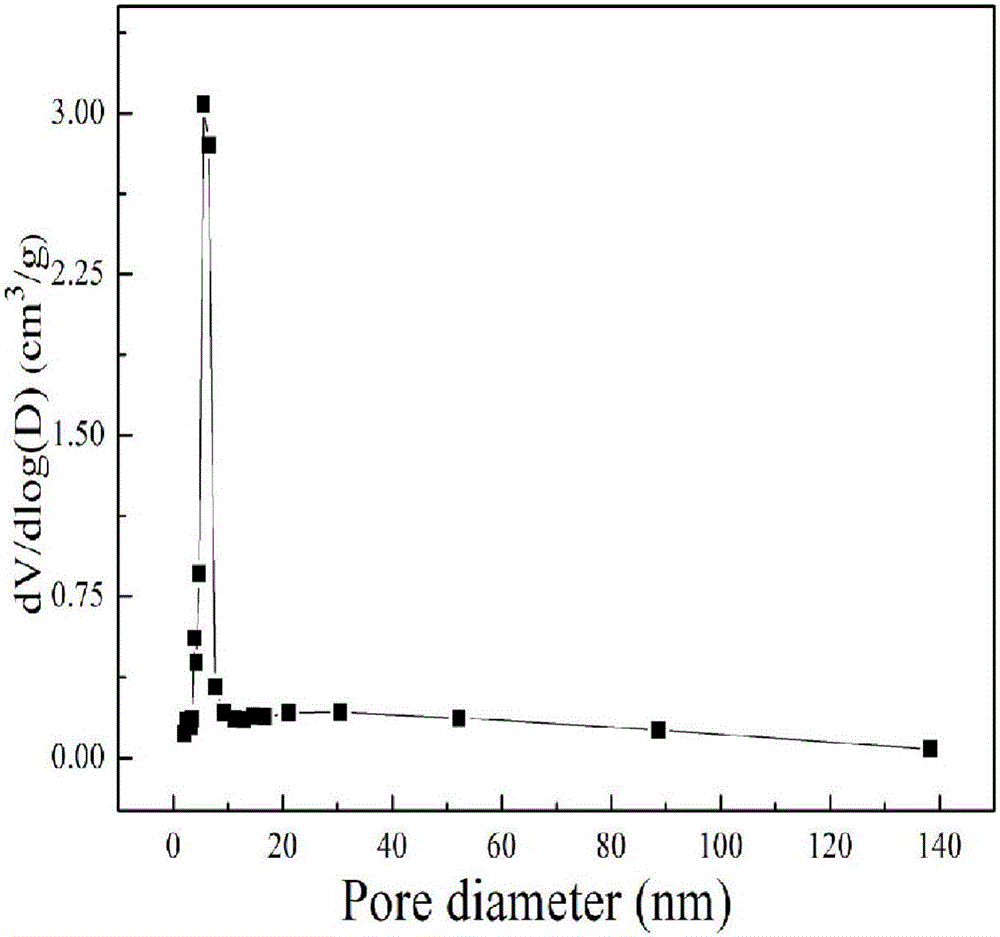

[0031] 1. Preparation of mesoporous silica

[0032] Add 120mL of 2mol / L hydrochloric acid solution and 4g of triblock copolymer P123 into the three-necked flask, set the temperature to 40°C, stir until P123 is completely dissolved, then add 10mL of tetraethyl orthosilicate (TEOS) at 40°C Pre-hydrolyze for 1.5h, then add 1mL KH550, stir and react at 40°C for 20h to obtain a suspension; place the resulting suspension at 100°C for 24h, filter with suction to obtain a white solid, dry and extract by Soxhlet (150ml (without Water and ethanol): 1.5mL concentrated hydrochloric acid: 1g (powder), time 48h, temperature 85°C) to obtain amino-modified mesoporous silica.

[0033]2. Preparation of cationic membrane for diffusion dialysis

[0034] (1) Weigh the mesoporous silica and sulfonated polyphenylene oxide prepared in step 1 according to the mass ratio of sulfonated polyphenylene ether to mesoporous silica at a ratio of 1:0.02; add mesoporous silica to DMF, and ultrasonically Dispe...

Embodiment 2

[0043] In this example, mesoporous silica and a cationic membrane for diffusion dialysis were prepared under the same conditions as in Example 1, and the same performance test was performed on them, the difference being the mass ratio of sulfonated polyphenylene ether to mesoporous silica in this example 1:0.04.

[0044] After testing, the performance parameters of the cationic membrane for diffusion dialysis obtained in this embodiment are: the water content of the membrane (W R ) is 193.66%, the ion exchange capacity is 0.20mmol / g, OH - Dialysis coefficient U OH It is 0.009m / h, and the separation coefficient is 31.0.

Embodiment 3

[0046] In this example, mesoporous silica and a cationic membrane for diffusion dialysis were prepared under the same conditions as in Example 1, and the same performance test was performed on them, the difference being the mass ratio of sulfonated polyphenylene ether to mesoporous silica in this example It is 1:0.06.

[0047] After testing, the performance parameters of the cationic membrane for diffusion dialysis obtained in this embodiment are: the water content of the membrane (W R ) is 160%, the ion exchange capacity is 0.20mmol / g, OH - Dialysis coefficient U OH It is 0.012m / h, and the separation coefficient is 40.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com