Granular iron preparation method and system

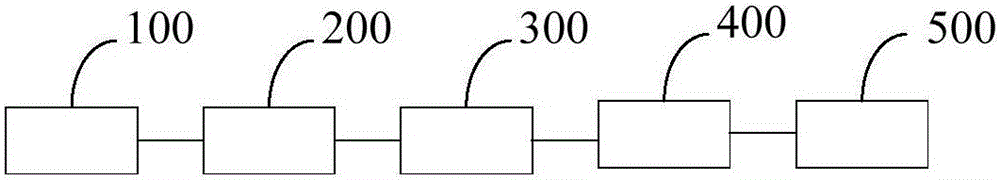

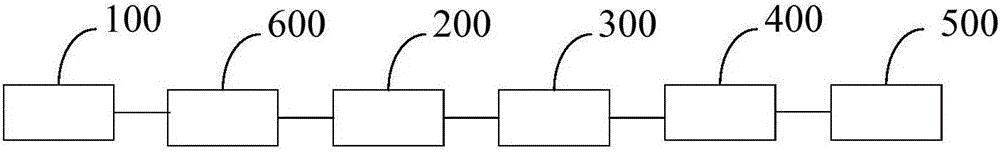

A technology for granulated iron and slag particles, which is applied in the field of the system for preparing granulated iron, can solve the problems of difficulty in engineering application, low thermal conductivity of slag, low thermal conversion efficiency, etc. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

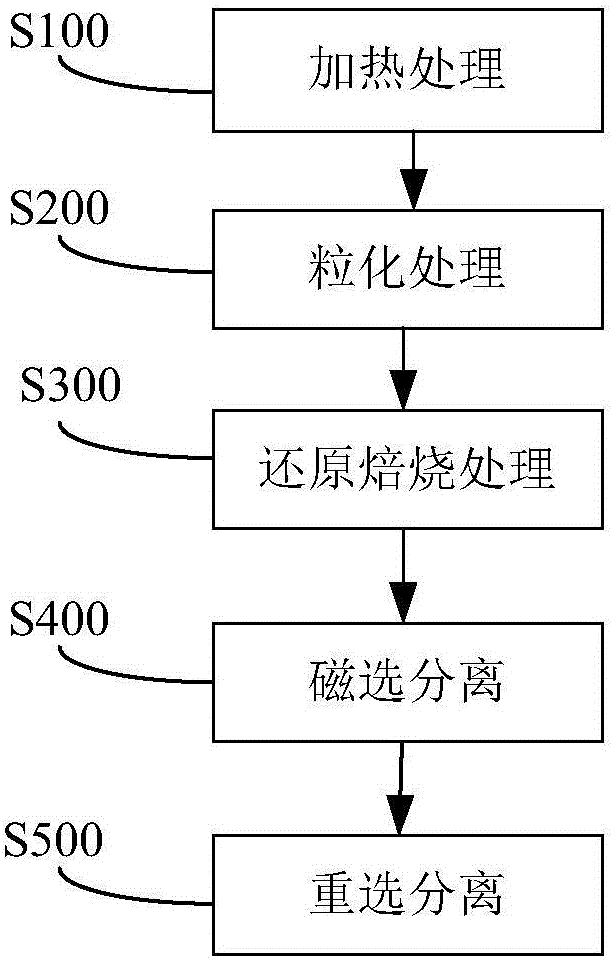

[0060] The high-temperature molten copper slag discharged from the copper smelting furnace is used as raw material to prepare iron granules. The specific method is as follows:

[0061] (1) The high-temperature molten copper slag discharged from the copper smelting furnace at a temperature of 1150 to 1350°C is poured directly into the slagging furnace in hot state.

[0062] (2) Raise the temperature in the slagging furnace to 1400~1450℃, and add 10% of the weight of copper slag to the furnace through the charging port on the top of the slagging furnace, and a quicklime block with a particle size of 5-10mm, which is coated with refractory materials. After stirring the molten pool for 10 minutes by inserting the mechanical stirring paddle into the molten slag, add heat to the furnace again, and keep it for 10 minutes to fully homogenize to obtain a homogenized mixed molten copper slag.

[0063] (3) Pour the homogenized mixed molten copper slag into the tundish, and flow into the granula...

Embodiment 2

[0068] The high-temperature molten copper slag discharged from the copper smelting furnace is used as the raw material to prepare iron granules.

[0069] (1) The high-temperature molten copper slag discharged from the copper smelting furnace at a temperature of 1150 to 1350°C is poured directly into the slagging furnace in hot state.

[0070] (2) Raise the temperature in the slagging furnace to 1380~1430℃, and add 20% of the weight of copper slag to the furnace through the charging port on the top of the slagging furnace, and a limestone block with a particle size of 10-15mm, which is coated with refractory materials. After stirring the molten pool for 20 minutes with the mechanical stirring blade inserted into the molten slag, the furnace is heated again, and the temperature is kept for 10 minutes to fully homogenize, and a homogenized mixed molten copper slag is obtained.

[0071] (3) Pour the homogenized copper slag into the tundish, and flow it into the granulator through the sla...

Embodiment 3

[0076] The high-temperature molten copper slag discharged from the copper smelting furnace is used as the raw material to prepare iron granules.

[0077] (1) The high-temperature molten copper slag discharged from the copper smelting furnace at a temperature of 1150 to 1350°C is poured directly into the slagging furnace in hot state.

[0078] (2) Raise the temperature in the slagging furnace to 1350~1400℃, and add 30% of the weight of copper slag to the furnace and a limestone block with a particle size of 15-20mm through the charging port on the top of the slagging furnace. After stirring the molten pool for 20 minutes with the mechanical stirring blade inserted into the molten slag, the furnace is heated again, and the temperature is kept for 20 minutes to fully homogenize to obtain a homogenized mixed molten copper slag.

[0079] (3) Pour the homogenized mixed molten copper slag into the tundish, and flow it into the granulator through the slag port, control the rotating cup of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com