Beta-dextran detection method based on fluorescence enhancement principle

A technology of fluorescence enhancement and detection method, which is applied in the field of fluorescence enhancement and achieves the effects of simple and effective method, wide application range and simple preparation device

- Summary

- Abstract

- Description

- Claims

- Application Information

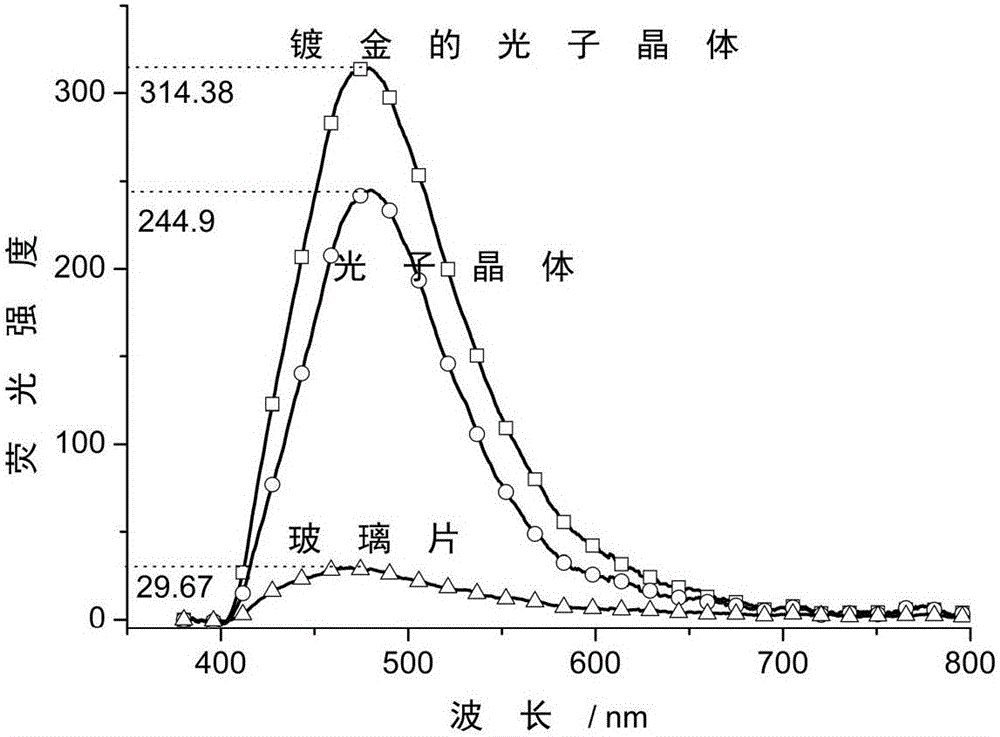

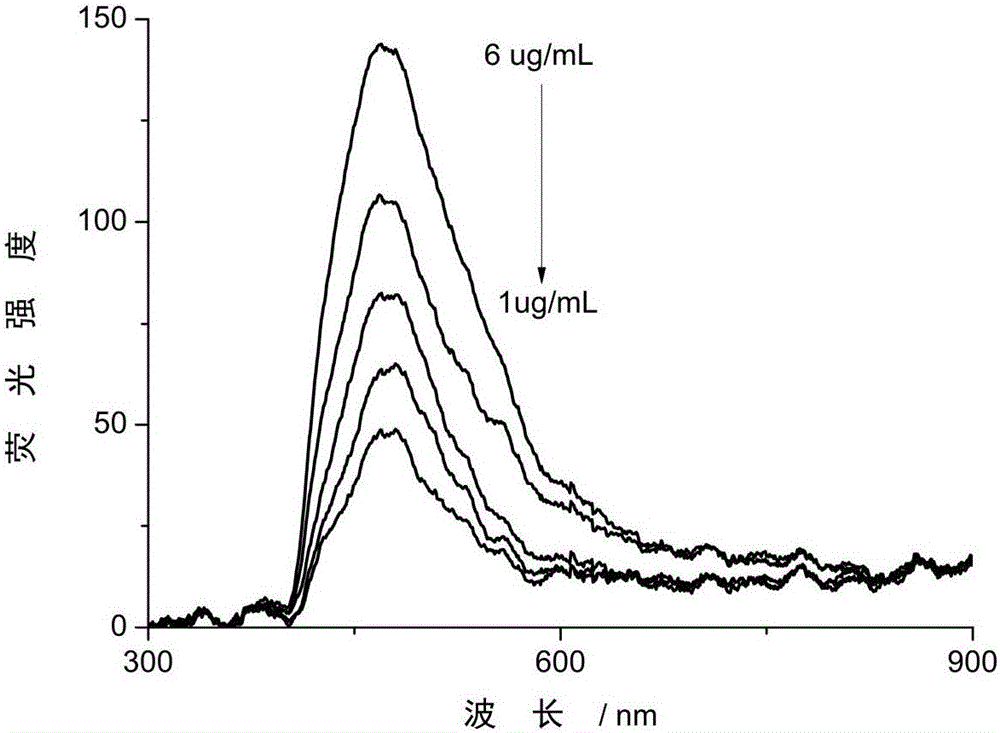

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Dip the silicon wafer in acetone solution for 30 minutes, then immerse it in ethanol solution for 30 minutes, and finally immerse it in H2O with a volume ratio of 1:3 2 SO 4 / H 2 o 2 Soak in the mixed solution for 12h, N 2 Blow dry to obtain a clean blank silicon wafer.

[0040] 2) Weigh 4g of tetrabutyl titanate and add it to 16ml of ethanol, slowly add 2ml of glacial acetic acid dropwise under magnetic stirring, and stir at room temperature for 5h to obtain light yellow transparent TiO with a concentration of 39mg / ml. 2 colloidal solution. Dissolve GO in water to make a GO colloid solution with a concentration of 0.25 mg / ml, pour the prepared 0.25 mg / mL GO hydrogel into a high-pressure reactor, and react at 90 ° C for 17 hours to obtain a concentration of 0.25 mg / ml. ml of GO hydrogel.

[0041] 3) TiO layer by layer 2 The colloidal solution and GO hydrogel were spin-coated onto the surface of the substrate, the spin-coating speed was 4500rpm, the spin-coatin...

Embodiment 2

[0049] 1) Dip the silicon wafer in acetone solution for 30 minutes, then immerse it in ethanol solution for 30 minutes, and finally immerse it in H 2 SO 4 / H 2 o 2 Soak in the mixed solution for 4h, N 2 Blow dry to obtain a clean blank silicon wafer.

[0050] 2) Weigh 4g of tetrabutyl titanate and add it to 16ml of ethanol, slowly add 2ml of glacial acetic acid dropwise under magnetic stirring, and stir at room temperature for 6h to obtain TiO with a concentration of 39mg / ml. 2 colloidal solution, and then diluted 3-fold to obtain a TiO concentration of 13 mg / ml 2 colloidal solution. Dissolve GO in water to make a GO colloid solution with a concentration of 0.5 mg / ml, pour the prepared 0.5 mg / mL GO hydrogel into a high-pressure reactor, and react at 90 ° C for 18 hours to obtain a concentration of 0.5 mg / ml. ml of GO hydrogel.

[0051] 3) TiO layer by layer 2 The colloidal solution and GO hydrogel were spin-coated onto the surface of the substrate, the spin-coating spe...

Embodiment 3

[0057] 1) Dip the silicon wafer in an acetone solution for 60 minutes, then immerse it in an ethanol solution for 60 minutes, and finally immerse it in H2O with a volume ratio of 3:7. 2 SO 4 / H 2 o 2 Soak in the mixed solution for 12h, N 2 Blow dry to obtain a clean blank silicon wafer.

[0058] 2) Weigh 4g of tetrabutyl titanate and add it to 16ml of ethanol, slowly add 2ml of glacial acetic acid dropwise under magnetic stirring, and stir at room temperature for 5h to obtain TiO with a concentration of 39mg / ml. 2 colloidal solution, and then diluted 5-fold to obtain a concentration of 7.8 mg / ml TiO 2 colloidal solution. Dissolve GO in water to prepare a GO colloid solution with a concentration of 0.25 mg / ml. Pour the prepared 0.25 mg / mL GO hydrogel into an autoclave and react at 100°C for 17 hours to obtain a concentration of 0.25 mg / ml. ml of GO hydrogel.

[0059] 3) TiO layer by layer 2 The colloidal solution and GO hydrogel were spin-coated onto the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com