Flue gas desulfurization and denitration method

A technology for desulfurization, denitrification, and flue gas, which is applied in the field of flue gas purification, can solve the problems of impact and low denitrification efficiency, and achieve the effects of high efficiency, small equipment footprint, and low investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

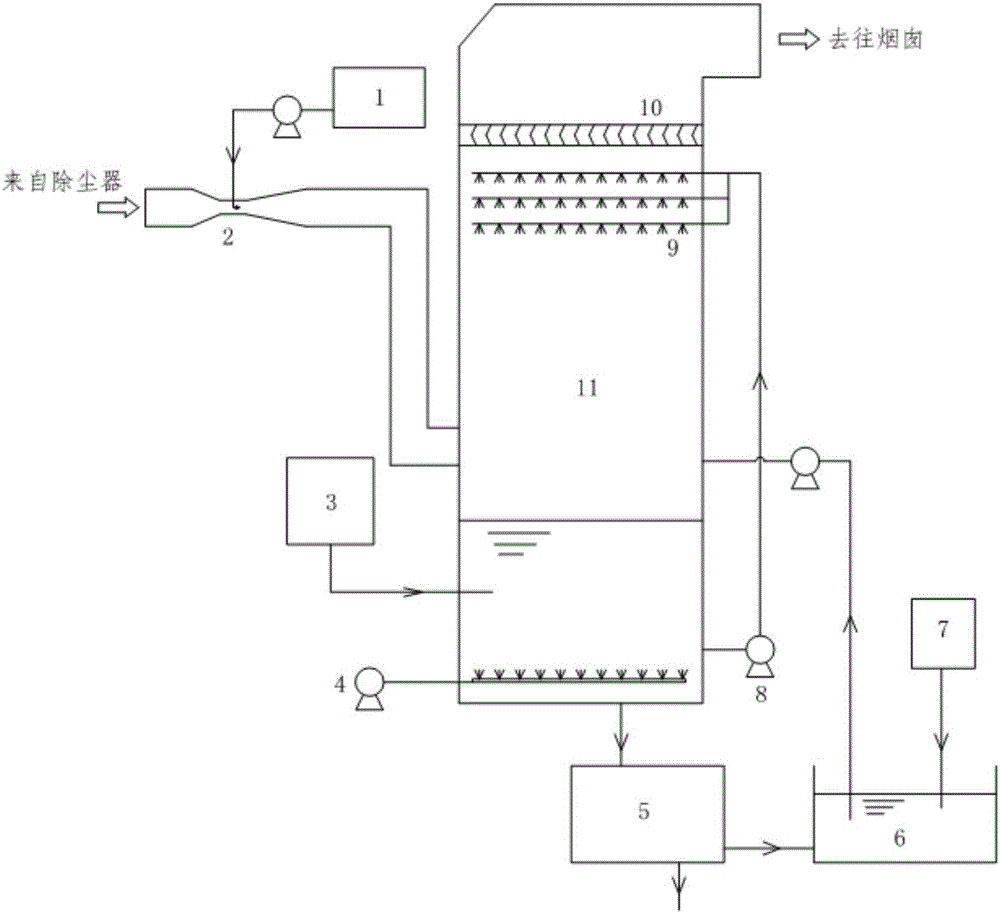

[0061] The method of flue gas desulfurization and denitrification in this embodiment will be specifically described by taking the flue gas treatment of a coal-fired power plant as an example.

[0062] The temperature of flue gas after dust removal in a coal-fired power plant is 190°C, SO 2 The concentration is 800mg / m 3 , NO concentration is 600mg / m 3 . 2% hydrogen peroxide solution is stored, and the flue gas after dust removal enters the Venturi mixer 2 and mixes with the 2% hydrogen peroxide solution in the hydrogen peroxide solution storage tank 1 . Hydrogen peroxide converts part of the SO 2 and NO are oxidized to SO 3 and NO 2 . Then the flue gas enters the absorption tower 11, and the SO produced by pre-oxidation 3 and NO 2 Dissolved in the absorption liquid to generate sulfuric acid and nitric acid respectively, at the same time, ethylenediamine cobalt in the absorption liquid catalyzes the oxidation of residual NO into high-valence nitrogen oxides. The alkali...

Embodiment 2

[0069] The method of flue gas desulfurization and denitrification in this embodiment is described by taking the treatment of flue gas from a sintering machine in a steel plant as an example.

[0070] The temperature of the flue gas from a sintering machine in a steel plant is 150°C after dust removal and waste heat recovery, SO 2 The concentration is 2000mg / m 3 , NO concentration is 700mg / m 3 . The flue gas after dedusting enters Venturi mixer 2 and mixes with 10% hydrogen peroxide solution. Hydrogen peroxide converts part of the SO 2 and NO are oxidized to SO 3 and NO 2 . Then the flue gas enters the absorption tower 11, and the SO produced by pre-oxidation 3 and NO 2 Dissolved in the absorption liquid to generate sulfuric acid and nitric acid respectively, at the same time, ethylenediamine cobalt in the absorption liquid catalyzes the oxidation of residual NO into high-valence nitrogen oxides. The alkaline slurry is 5% urea solution, and the amount of urea solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com