A kind of preparation method of silicon dioxide for washing powder with high oil absorption value and high water absorption

A technology of silicon dioxide and water absorption, applied in the directions of silicon dioxide, silicon oxide, chemical instruments and methods, etc., can solve the problem of insufficient water absorption and oil absorption, save the cumbersome pH value control, and improve water absorption. , the effect of loose structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

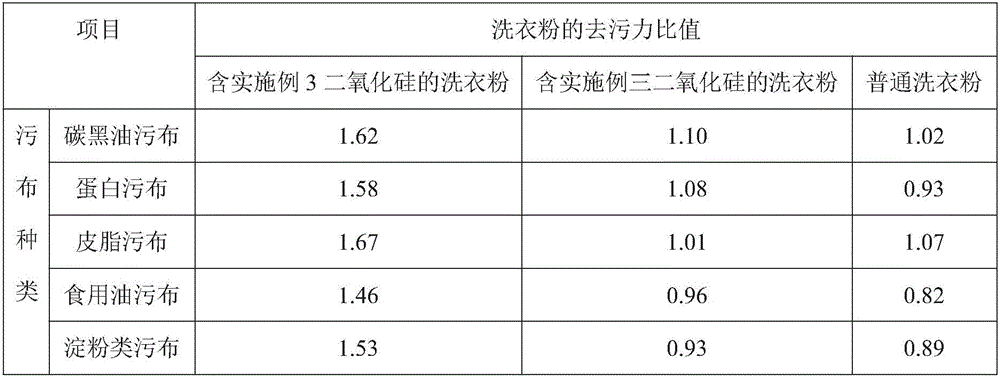

Examples

Embodiment 1

[0022] Embodiment 1, the preparation method of silicon dioxide for washing powder with high oil absorption value and high water absorption capacity of the present invention

[0023] S1, the SiO 2 :Na 2 The solid sodium silicate with O=3.3~3.45 is pressurized and heated to be liquefied, and then added with water to prepare a sodium silicate solution with a concentration of 2.0M, and prepare a saturated sodium bicarbonate solution for subsequent use;

[0024] S2, add 7m in reaction tank 3 water, warming up to 40°C, then adding 3.0m of saturated sodium bicarbonate solution dropwise at the same time 3 and 2.0M sodium silicate solution 3.5m 3 , controlled to finish dripping within 25 minutes, forming sol-like silica;

[0025] S3, heat up to 75°C, continue to add 5.2m of 2.0M sodium silicate solution to the reaction tank 3 , and then dropwise added saturated sodium bicarbonate solution 4.5m 3 , after the dropwise addition, titrate with 4M sulfuric acid until the end point pH i...

Embodiment 2

[0028] Embodiment 2, the preparation method of silicon dioxide for washing powder with high oil absorption value and high water absorption capacity of the present invention

[0029] S1, the SiO 2 :Na 2 The solid sodium silicate with O=3.3~3.45 is pressurized and heated to be liquefied, and then added with water to prepare a sodium silicate solution with a concentration of 0.8M, and prepare a saturated sodium bicarbonate solution for subsequent use;

[0030] S2, add 5m in reaction tank 3 water, warm up to 45°C, then add 2.2m of saturated sodium bicarbonate solution dropwise at the same time 3 and 0.8M sodium silicate solution 2.8m 3 , controlled to finish dripping within 35 minutes, forming sol-like silica;

[0031] S3, heat up to 65°C, continue to add 4.4m of 0.8M sodium silicate solution to the reaction tank 3 , and then dropwise add saturated sodium bicarbonate solution 3.5m 3 , after the dropwise addition, titrate with 4M sulfuric acid until the end point pH is 3, and...

Embodiment 3

[0034] Embodiment 3, the preparation method of silicon dioxide for washing powder with high oil absorption value and high water absorption capacity of the present invention

[0035] S1, the SiO 2 :Na 2 The solid sodium silicate with O=3.3~3.45 is pressurized and heated to be liquefied, and then added with water to prepare a sodium silicate solution with a concentration of 1.0M, and prepare a saturated sodium bicarbonate solution for subsequent use;

[0036] S2, add 6m in reaction tank 3 water, warming up to 40°C, then adding 2.7m saturated sodium bicarbonate solution dropwise at the same time 3 and 1.0M sodium silicate solution 3.2m 3 , controlled to finish dripping within 30 minutes, forming sol-like silica;

[0037] S3, heat up to 70°C, continue to add 4.8m of 1.0M sodium silicate solution to the reaction tank 3 , then dropwise add saturated sodium bicarbonate solution 4.0m 3 After the dropwise addition, titrate with 4M sulfuric acid until the end point pH is 6, and ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com