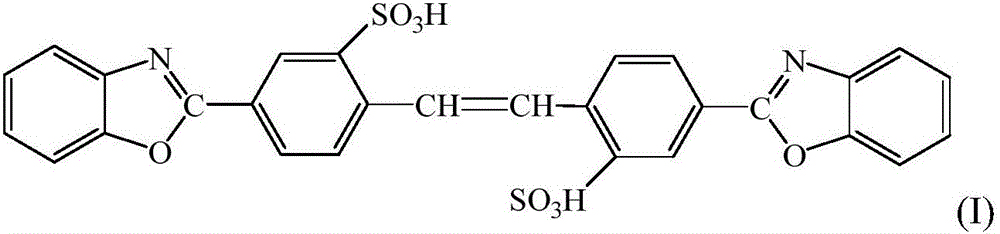

Anti-ultraviolet fluorescent whitening agent emulsion

A fluorescent whitening agent and anti-ultraviolet technology, applied in the direction of organic dyes, methine/polymethine dyes, styrene-based dyes, etc., can solve poor whitening effect, affect product appearance, increase the amount of brightener, etc. Problems, to achieve significant UV protection effect, improve user experience, and reduce potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 15g of fluorescent whitening agent to 20g of water, stir until completely dissolved, then add 4g of polyethylene glycol 400, 4g of sodium dodecylsulfonate, 6g of 2-hydroxy-4-acrylate benzophenone and 60g of petroleum ether, after 30 minutes of emulsification at room temperature using an emulsifier, stop the emulsification and just let it stand, and let it stand at room temperature for 2 weeks without delamination.

Embodiment 2

[0026] Add 20g of fluorescent whitening agent to 30g of water, stir until completely dissolved, then add 2.5g of polyethylene glycol 600, 7.5g of sodium dodecylsulfonate, 5g of 2-methyldibenzoylmethane and 70g of petroleum Ether, use an emulsifier to emulsify at room temperature for 30 minutes, stop the emulsification, and let it stand still, and stand at room temperature for 2 weeks without delamination.

Embodiment 3

[0028] Add 30g of fluorescent whitening agent to 40g of water, stir until completely dissolved, then add 4g of polyethylene glycol 400, 8g of sodium dodecylsulfonate, 8g of 2-hydroxy-4-acrylate benzophenone and 80g of petroleum ether, emulsified by emulsifier at room temperature for 30 minutes, stop emulsification, just let it stand, stand at room temperature for 2 weeks without delamination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com