Method for stably growing GaN crystal material at high rate in HVPE

A crystal material, high-speed technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of hindering GaN materials, hindering GaN crystal rate, GaN corrosion, etc., to achieve the effect of increasing growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

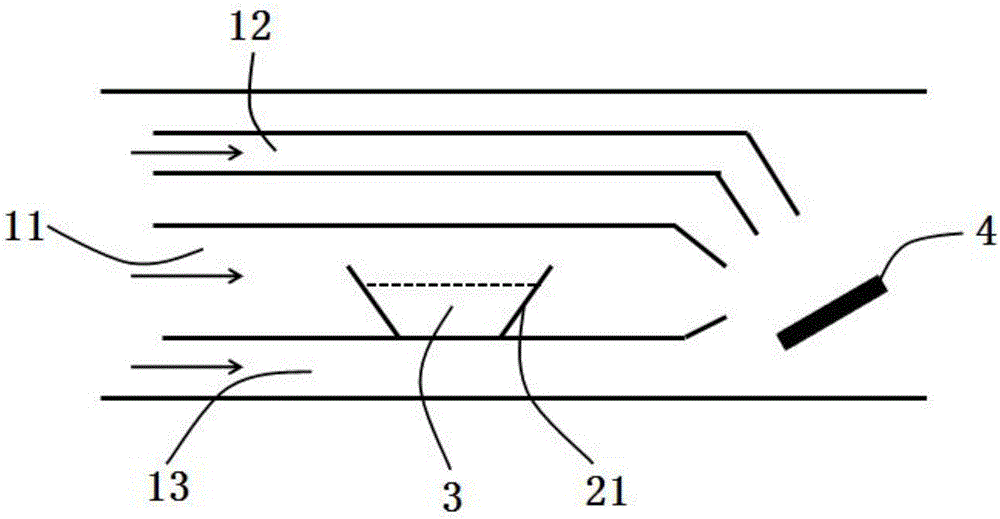

[0030] Embodiment one: as attached figure 2 As shown, in the horizontal HVPE system, the improved tortuous and extended HCl gas circulation path is adopted, and the HCl gas 11 is passed in from the lower side of the Ga boat 22, passing through the Ga in the HCl gas inlet and the liquid Ga. A zigzag and extended circulation path provided between the liquid surfaces of the boat 22, which is partly separated but communicated. In this way, the HCl gas 11 and the liquid metal Ga 3 have enough time to fully mix and completely react to generate GaCl gas; the GaCl gas generated by the reaction escapes from the upper liquid level of the liquid metal Ga 3 and is transported to the growth zone. near seed 4, with NH 3 12 reaction to generate GaN crystal material. Due to the tortuous and extended circulation path, the contact area between the HCl gas 11 and the liquid Ga 3 is increased and the reaction time is prolonged, so that the GaCl gas 11 and the liquid Ga 3 are fully contacted a...

Embodiment 2

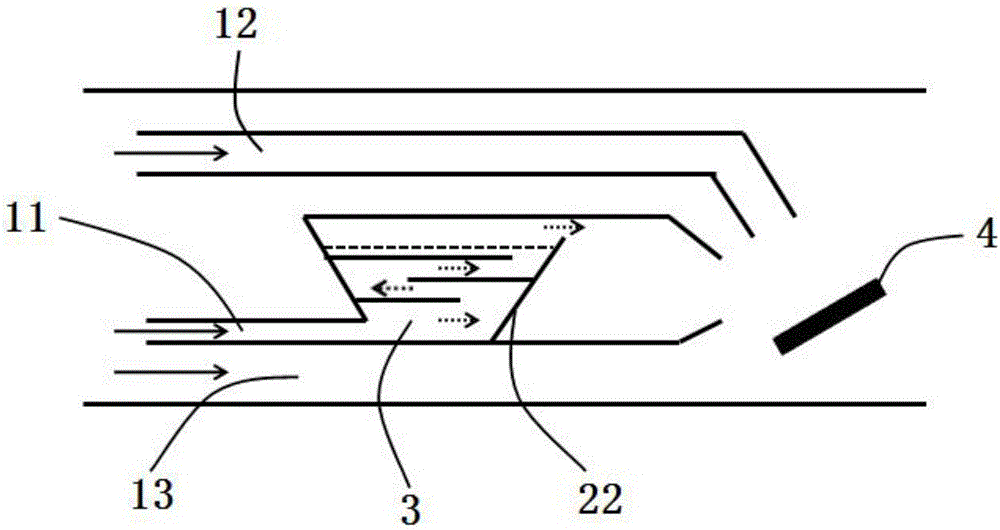

[0032] Embodiment two: as attached image 3As shown, in the horizontal HVPE system, the improved distribution path of the diffused HCl gas of the present invention is adopted, and the porous inlet diffused from the bottom of the Ga boat 23 is uniformly fed into the HCl gas 11 . Since each inlet of HCl gas is small and spread out, the small flow of HCl gas 11 emerging upward from each HCl inlet fully contacts with liquid Ga 3 to completely react to generate GaCl gas, therefore, there is almost no unreacted HCl gas 11 escapes from the liquid surface of liquid Ga 3 . Afterwards, the GaCl gas generated by the reaction escapes from the upper liquid level of the liquid Ga 3 and is transported to the vicinity of the seed crystal 4 in the reaction zone, and NH 3 12 reaction to generate GaN crystal material. Since there is no HCl gas near the seed crystal 4, the growth rate of the GaN crystal material is improved; and as the reaction continues, although the liquid level of the liqui...

Embodiment 3

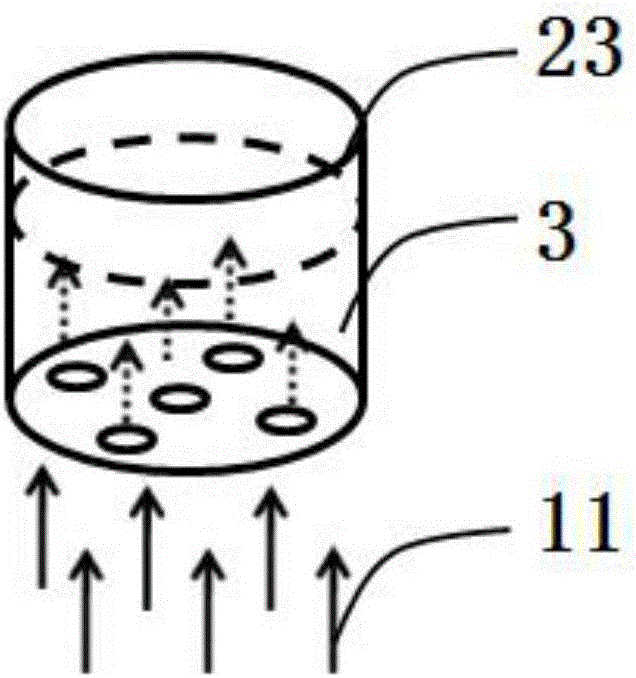

[0034] Embodiment three: as attached Figure 4 As shown, in the vertical HVPE system, the diffused circulation path in Embodiment 2 and the tortuous and extended circulation path in Embodiment 1 are used in combination, and the HCl gas 11 is transferred from the circular ring of liquid Ga on the upper part of the Ga boat 24 The liquid surface of the circular ring outside the shape spreads out, bypasses the tortuous and extended circulation path in which the lower part is connected but the middle and upper parts are separated from each other, the HCl gas 11 is fully mixed with the liquid Ga 3 and reacts completely to form GaCl gas, from Ga boat 24 top liquid Ga inner ring liquid surface of the ring escapes; Through the tortuous and extended flow path, it fully contacts with liquid Ga3 and completely reacts to generate GaCl gas. Therefore, almost no unreacted HCl gas 11 escapes from the liquid surface of the inner ring of liquid Ga3. Finally, after the GaCl gas generated by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com