Direct combustion type waste gas treatment and heat energy utilization system and utilization method

A waste gas treatment, direct combustion technology, applied in the combustion method, combustion type, heating device and other directions, can solve the problems of harm to human health, secondary pollution, high energy consumption, etc., to achieve the effect of convenient incineration and reasonable utilization of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

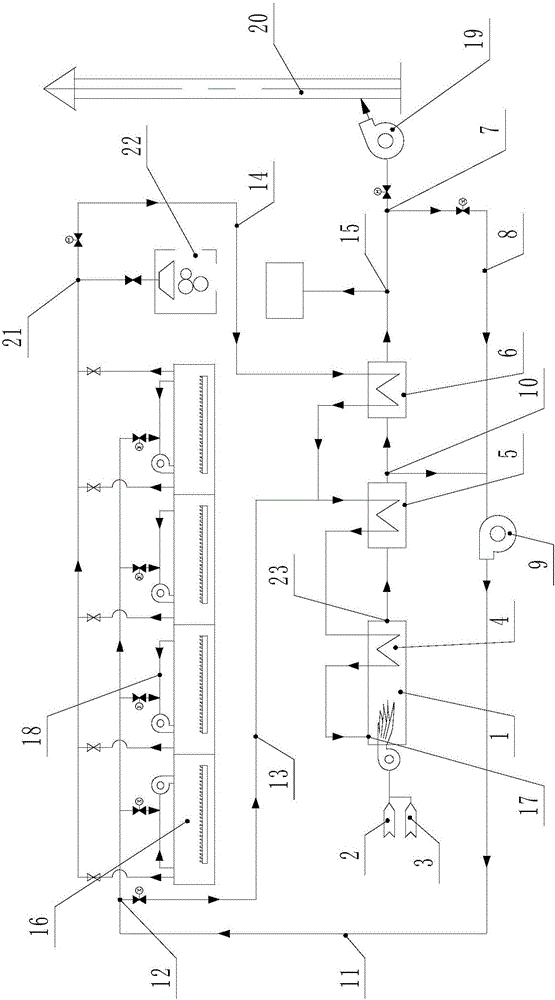

[0023] like figure 1 As shown, a direct-fired waste gas treatment and heat energy utilization system includes an oven 16, which is provided with a circulating air duct 18 with both ends communicating with the interior of the oven 16, and a circulating fan is arranged on the circulating air duct 18. This circulating air duct 18 is communicated with the hot blast supply system, and the hot blast supply system includes an incinerator 1, and the incinerator 1 is provided with an incinerator, and the incinerator is connected with the fuel supply pipe 2 and the combustion air supply pipe 3, and the incinerator 1 is provided with an exhaust port 23 and a waste gas recovery port 17. The waste gas recovery port 17 corresponds to the combustion position of the incinerator 1. The recovered organic waste gas is directly burned and decomposed into carbon dioxide and water at the combustion position. The waste gas recovery port 17 It communicates with the oven 16 through the waste gas recov...

Embodiment 2

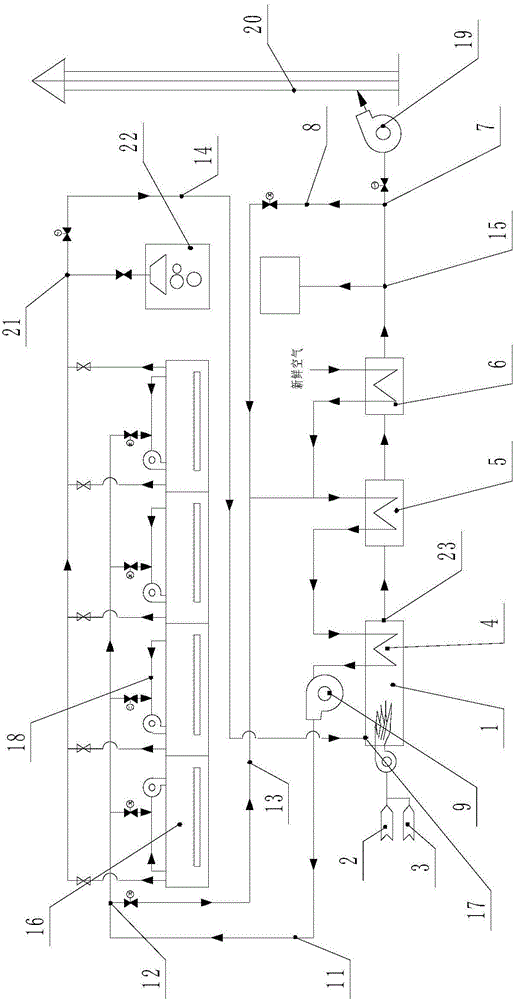

[0033] like figure 2 As shown, the basic idea of this embodiment is the same as that of the embodiment, both are to collect the organic waste gas produced by the oven and send it to the incinerator 1 for incineration, but the hot air generated after incineration in the incinerator 1 is not directly supplied To the oven 16, the reason is mainly to prevent the incomplete combustion of the organic waste gas in the incinerator 1, thereby causing the hot air generated by the combustion to bring new pollution to the oven 16 when the hot air is sent to the oven 16. At this time, the air supply pipeline 11 Directly communicate with the fresh air source, then the air supply line 11 exchanges heat with the hot air burned by the incinerator 1, and the fresh air is heated to a certain stability and then supplied to the oven 16 for heating. At this time, the air supply pipeline 11 is not communicated with the exhaust pipeline, but is communicated with the fresh air source, and the air s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com