Preparation method and application of schottky junction explosive atmosphere sensing material

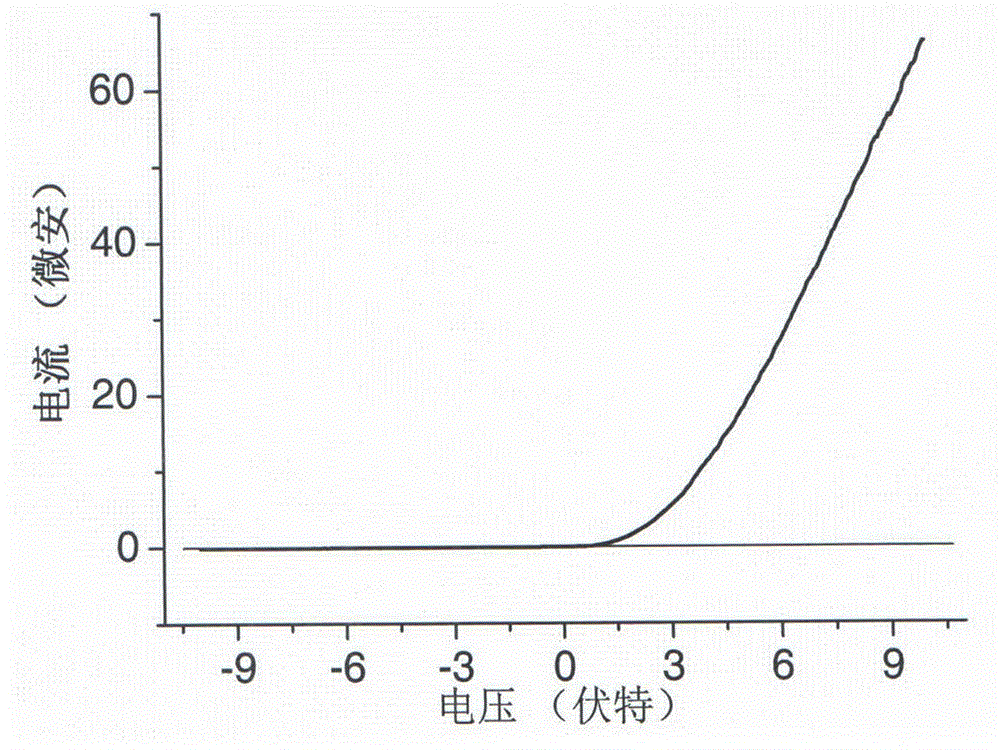

A technology of Schottky junction and sensing materials, which is applied in the direction of analyzing materials, analyzing materials through electromagnetic means, measuring devices, etc., and can solve problems such as complex components and difficult detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

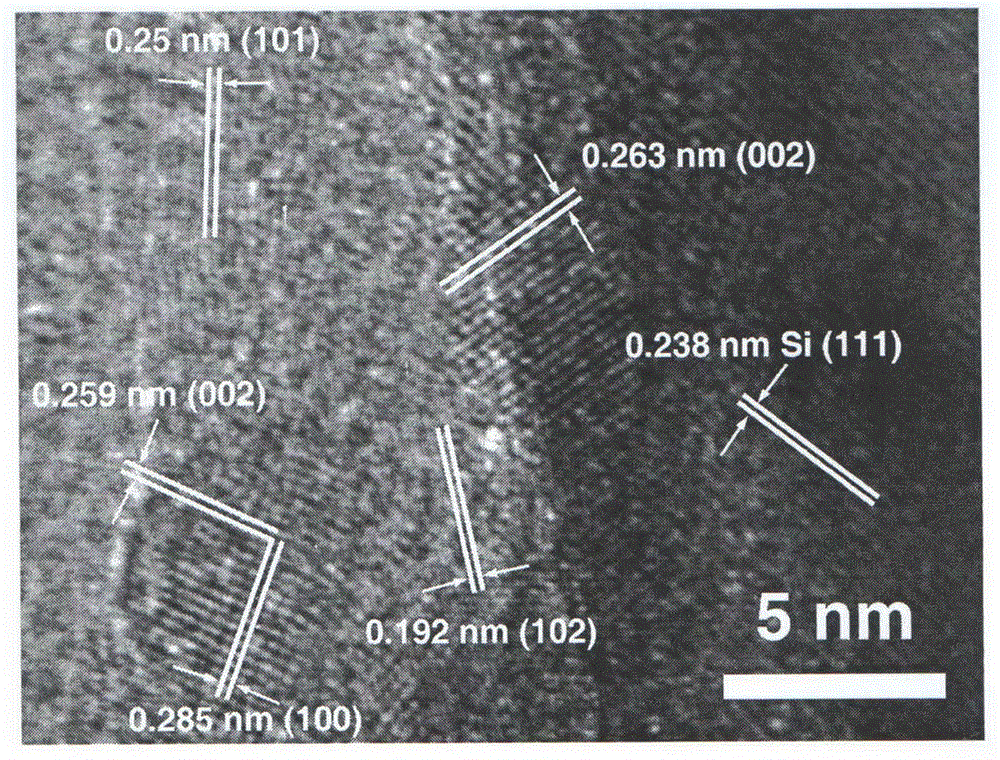

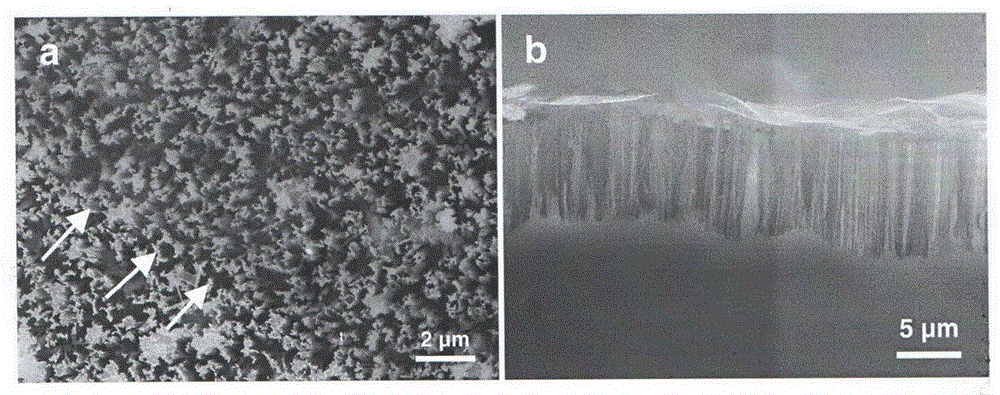

[0032] a. The silicon nanowire array prepared by conventional chemical etching method is used as the substrate, and the absolute ethanol solution of zinc acetate with a concentration of 0.005mol / L is prepared, added dropwise to the silicon nanowire, and dried with nitrogen, Take it out after annealing at 350°C for 0.5h to obtain a ZnO seed-modified silicon nanowire array;

[0033] B, configuration 125mL concentration is respectively the methanol solution of zinc acetate of 0.001mol / L and the methanol solution of potassium hydroxide of 0.003mol / L 65mL concentration, potassium hydroxide solution is added in the zinc acetate solution drop by drop, and step Put the silicon nanowire array modified by ZnO seed crystals obtained in a into the mixed solution, react at a temperature of 60°C for 2 hours, and then repeat the process of step b twice to obtain a silicon-zinc oxide core-shell nanowire array;

[0034] c, transferring the graphene obtained by the wet chemical method to the to...

Embodiment 2

[0038] a. The silicon nanowire array prepared by conventional chemical etching method is used as the substrate, and the absolute ethanol solution of zinc acetate with a concentration of 0.005mol / L is prepared, added dropwise to the silicon nanowire, and dried with nitrogen, Take it out after annealing at 350°C for 0.5h to obtain a ZnO seed-modified silicon nanowire array;

[0039] B, configuration 125mL concentration is respectively the methanol solution of zinc acetate of 0.001mol / L and the methanol solution of potassium hydroxide of 0.003mol / L 65mL concentration, potassium hydroxide solution is added in the zinc acetate solution drop by drop, and step Put the silicon nanowire array modified by ZnO seed crystal obtained in a into the mixed solution, react at a temperature of 50° C. for 2 hours, and then repeat the process of step b once to obtain a silicon-zinc oxide core-shell nanowire array;

[0040] c, transferring the graphene obtained by the wet chemical method to the to...

Embodiment 3

[0044] a. The silicon nanowire array prepared by conventional chemical etching method is used as the substrate, and the absolute ethanol solution of zinc acetate with a concentration of 0.005mol / L is prepared, added dropwise to the silicon nanowire, and dried with nitrogen, Take it out after annealing at 350°C for 0.5h to obtain a ZnO seed-modified silicon nanowire array;

[0045] b, configure 125mL concentration of methanol solution of zinc acetate of 0.05mol / L and 65mL concentration of methanol solution of potassium hydroxide of 0.15mol / L respectively, add potassium hydroxide solution drop by drop in the zinc acetate solution, and step Put the silicon nanowire array modified by ZnO seed crystals obtained in a into the mixed solution, react at a temperature of 80°C for 2 hours, and repeat the process of step b for 3 times to obtain a silicon-zinc oxide core-shell nanowire array;

[0046] c, transferring the graphene obtained by the wet chemical method to the top of the silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com