Rare-earth permanent magnet and fabrication method thereof

A rare-earth permanent magnet and magnet technology, which is applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., can solve problems such as insufficient diffusion, insignificant coercivity effect, magnet remanence and squareness deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a method for preparing rare earth permanent magnets, which includes the following steps:

[0032] S1, respectively providing a master alloy magnetic powder and a low melting point alloy, and the low melting point alloy is a rare earth-transition metal alloy;

[0033] S2, hot-press forming the mother alloy magnetic powder under vacuum conditions to obtain a hot-pressed magnet;

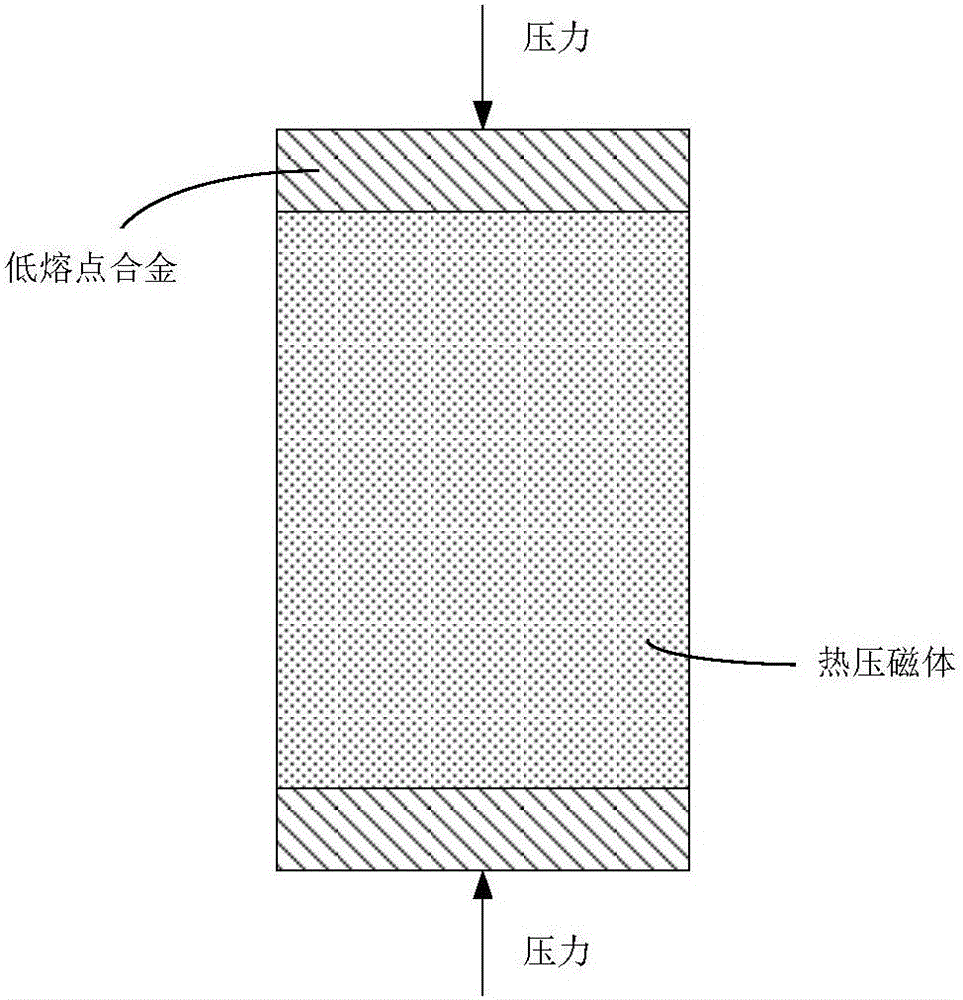

[0034] S3, covering the low-melting point alloy on the end surface of the hot-pressed magnet, and simultaneously pressing the low-melting-point alloy and the hot-pressed magnet in an argon atmosphere to perform hot deformation molding to obtain a hot-deformed magnet;

[0035] S4, performing two-stage heat treatment on the thermally deformed magnet to obtain a rare earth permanent magnet.

[0036] In step S1, the preparation method of the low melting point alloy is specifically as follows:

[0037] S11, according to the proportion of the elements in the low melting point alloy;...

Embodiment 1

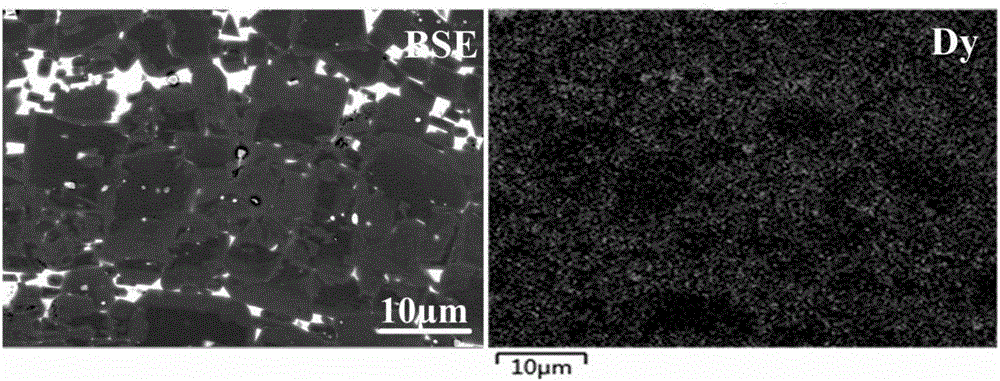

[0057] According to dysprosium copper alloy (Dy 85.65 Cu 14.35 ) The proportions of dysprosium and copper are accurately mixed, and the ingot is made in a vacuum induction melting furnace. The ingot is cut into a block of dysprosium copper alloy with an electric spark cutter, and the surface is processed with sandpaper of different sizes. Coarse grinding and fine grinding.

[0058] Set the ingredients to Nd 30 Ga 0.5 Fe bal. Co 4 B 1 The neodymium-iron-boron master alloy magnetic powder is induction heated in a vacuum environment. When the temperature rises to 200°C, the first pressure is applied to the first mold. The maximum temperature is controlled to 670°C to obtain a hot-pressed magnet, which rises from room temperature to The time for the highest temperature is 5 minutes to 6 minutes, the first pressure is 150 MPa, and the vacuum degree during the hot pressing process is better than 1×10 -1 Pa.

[0059] Put the hot-pressed blank into a second mold with a larger diameter, pl...

Embodiment 2

[0063] This preparation method is basically the same as Example 1, except that the first-stage heat treatment time in the two-stage heat treatment process is 30 minutes.

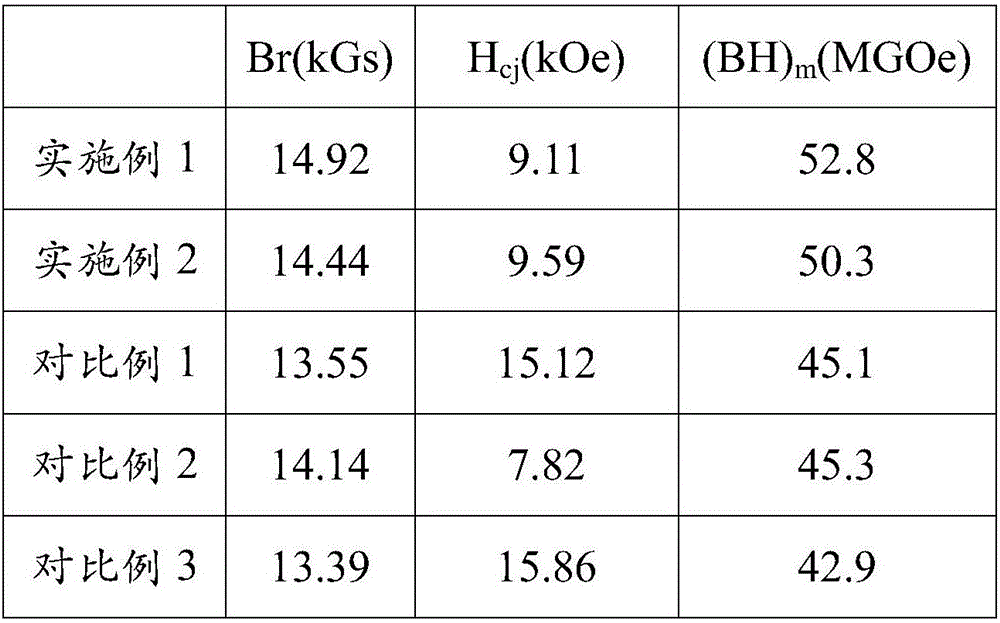

[0064] The magnetic properties of the obtained rare earth permanent magnets were tested at room temperature, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanence | aaaaa | aaaaa |

| Magnetic energy product | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com