Vegetable salt and method for preparing suaeda salsa vegetable salt by adopting biological heavy-metal-removing technology utilizing chitosan

A technology of Suaeda salsa and heavy metal removal, which is applied in the field of plant salt extraction to achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

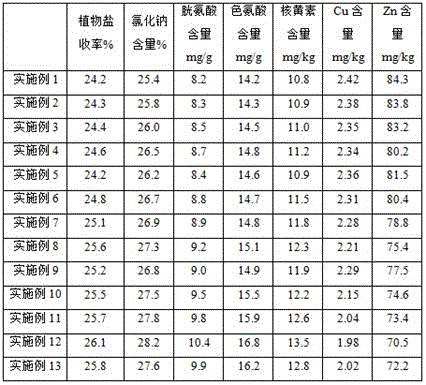

Examples

Embodiment 1

[0036] Example 1 A chitosan biosorbent

[0037] The biosorbent, in parts by weight, includes 7-8 parts of chitosan, 3-8 parts of carrageenan, 0.2-0.3 parts of Saccharomyces cerevisiae powder, 0.2-0.8 parts of Penicillium chrysogenum powder, 0.1-0.5 parts of Aureobasidium pullulans powder, 0.3-0.4 parts of Phanerochaete chrysosporium powder;

[0038] The Saccharomyces cerevisiae powder: containing 1.2×10 Saccharomyces cerevisiae 9 each / g, the carrier is potato starch;

[0039] The Penicillium chrysogenum powder: containing Penicillium chrysogenum 4 × 10 8 Individual / g, the carrier is corn starch;

[0040] The Aureobasidium pullulans powder: containing Aureobasidium pullulans 2 × 10 8 Individual / g, the carrier is corn starch;

[0041] The Phanerochaete chrysosporium bacteria powder: containing Phanerochaete chrysosporium 3 × 10 8 Individual / g, the carrier is soybean protein powder; the above-mentioned microorganisms are cultured by conventional culture methods respectively...

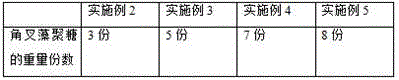

Embodiment 2

[0042] Example 2 Single factor analysis experiment of carrageenan content

[0043] A chitosan biosorbent, comprising the following raw materials: chitosan, carrageenan, Saccharomyces cerevisiae powder, Penicillium chrysogenum powder, Aureobasidium pullulans powder, Phanerochaete chrysosporium powder ;

[0044] The ratio of the following raw materials is unchanged: 7.5 parts of chitosan, 0.2 part of Saccharomyces cerevisiae powder, 0.5 part of Penicillium chrysogenum powder, 0.3 part of Aureobasidium pullulans powder, and 0.4 part of Phanerochaete chrysosporium powder; Only change the content proportioning of carrageenan, carry out embodiment 2-5; The parts by weight of the carrageenan that embodiment 2-5 adopts is shown in Table 1;

[0045] The parts by weight of the carrageenan that table 1 embodiment 2-5 adopts

[0046]

[0047] The Saccharomyces cerevisiae powder: containing 1.2×10 Saccharomyces cerevisiae 9 each / g, the carrier is potato starch;

[0048] The Penicill...

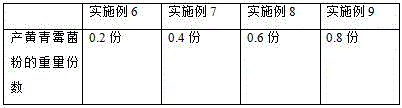

Embodiment 6

[0051] Example 6 Single factor analysis experiment of Penicillium chrysogenum powder content

[0052]A chitosan biosorbent, comprising the following raw materials: chitosan, carrageenan, Saccharomyces cerevisiae powder, Penicillium chrysogenum powder, Aureobasidium pullulans powder, Phanerochaete chrysosporium powder ;

[0053] The ratio of the following raw materials is unchanged: 7.5 parts of chitosan, 7 parts of carrageenan, 0.2 part of Saccharomyces cerevisiae powder, 0.3 part of Aureobasidium pullulans powder, and 0.4 part of Phanerochaete chrysosporium powder; Only change the content proportioning of Penicillium chrysogenum powder, carry out embodiment 6-9; The parts by weight of the Penicillium chrysogenum powder that embodiment 6-9 adopts is shown in Table 2;

[0054] The parts by weight of the Penicillium chrysogenum powder that table 2 embodiment 6-9 adopts

[0055]

[0056] The Saccharomyces cerevisiae powder: containing 1.2×10 Saccharomyces cerevisiae 9 each / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com